Composite Materials Extraordinaire: PA610 CF

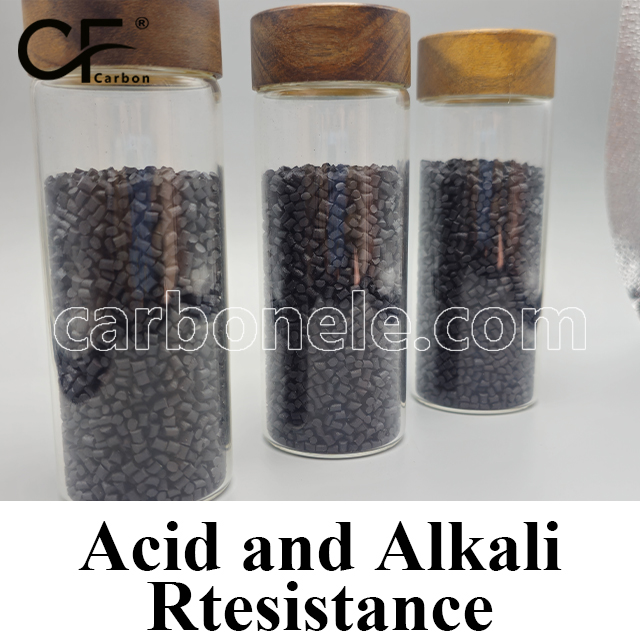

PP CF30 refers to a type of 30% carbon fiber reinforced polypropylene thermoplastic composite. It is typically formed by combining carbon fibers with polypropylene through specific processes and techniques. Excellent properties. It has high strength and stiffness, capable of withstanding considerable external forces without deformation. Simultaneously, it is relatively lightweight, which helps reduce the weight of products. It demonstrates good heat resistance and stability. PP CF30 finds applications in numerous fields such as automotive, aerospace, and electronics, bringing innovation and improvement to these industries.

PA610 CF (Carbon Fiber Reinforced PA610) has wide applications in various fields. In the aerospace industry, it is used to manufacture structural components of aircraft, such as wings and fuselages. Its lightweight and high strength help reduce the aircraft's weight and enhance fuel efficiency and flight performance. The automotive sector benefits from it as well. Components like engine parts and chassis elements can be made with PA610 CF, enabling lightweight design and ensuring the strength and durability of the vehicle to lower energy consumption and improve performance. It is also employed in the production of sports equipment. High-performance items like golf clubs, tennis rackets, and bicycle frames can be crafted from this material, offering better user experience and competitive advantages to athletes. In industrial equipment, it is suitable for manufacturing composite rollers and mechanical arms. While maintaining strength, it reduces the weight of the equipment and enhances production efficiency and operational stability. The medical device field utilizes its X-ray transmissibility to create mobile platforms for X-ray inspection devices. Its excellent mechanical properties also make it suitable for manufacturing orthopedic and organ transplant-related medical devices, as well as rehabilitation products like prosthetics and orthotics. In the energy sector, it can be used to produce gas diffusion layer electrode materials for proton exchange membrane fuel cells, or for manufacturing wind turbine blades, flywheels, and batteries, expanding its application in energy and energy storage. In rail transportation, it is a key material choice for the next generation of high-speed rail train bodies. It makes the train bodies lightweight, improves high-speed running performance, reduces energy consumption, and enhances safety. The application trend extends from non-load-bearing structural parts to load-bearing components and from small parts to large structures. In civil engineering, it is used to create composite rods, fiber-reinforced laminated plates, carbon fiber-reinforced concrete, and carbon fiber reinforcement materials, improving the brittleness and low tensile strength of cement and other materials, providing new material options for the civil construction field.

Product By Features

PA610-CF60 High-performance nylon material

PA610-CF60 is a high performance composite material reinforced with 60% carbon fiber, offering exceptional stiffness, strength, and wear resistance. It is ideal for extreme mechanical performance applications, maintaining excellent durability, thermal stability, and chemical resistance. PA610-CF60 provides outstanding wear resistance in high-friction conditions and is easily processed using standard thermoplastic…

Learn More

High-performance nylon material PA610-CF50

PA610-CF50 is a high performance composite material reinforced with 50% carbon fiber, offering exceptional stiffness, strength, and wear resistance. It is ideal for applications requiring superior mechanical performance in harsh environments. Despite the high fiber content, PA610-CF50 maintains good processability, making it suitable for demanding industries such as automotive, industrial…

Learn More

Carbon fiber nylon parts PA610-CF40

PA610-CF40 is a high-performance composite material reinforced with 40% carbon fiber, offering exceptional stiffness, strength, and wear resistance. With excellent thermal and chemical stability, it performs reliably in demanding environments. Suitable for automotive, industrial, electronics, and consumer goods applications, PA610-CF40 combines superior durability with ease of processing, making it ideal…

Learn More

PA610-CF30 Carbon fiber nylon parts

PA610-CF30 is a high performance composite material reinforced with 30% carbon fiber, offering superior stiffness, strength, and wear resistance compared to unreinforced PA610. It combines high mechanical performance with excellent dimensional stability, making it ideal for demanding applications in automotive, industrial manufacturing, electronics, and consumer goods. PA610-CF30 is also resistant…

Learn More

PA610-CF20 carbon fiber composite sheet

PA610-CF20 is a high performance material with 20% carbon fiber reinforcement, offering improved stiffness, strength, and wear resistance compared to unreinforced PA610. It maintains excellent processability and is ideal for moderate to demanding applications requiring enhanced durability and resistance to chemicals, oils, and moderate friction. With good thermal stability and…

Learn More

Carbon fiber composite sheet PA610-CF10

PA610-CF10 is a high performance thermoplastic reinforced with 10% carbon fiber, offering improved stiffness, strength, and wear resistance compared to unreinforced PA610. It maintains the flexibility and ease of processing typical of PA610, making it ideal for moderate to demanding applications in automotive, industrial manufacturing, electronics, and consumer goods. PA610-CF10…

Learn More

Carbon fiber composite sheet PA610-CF5

PA610-CF5 is a moderately reinforced composite material with 5% carbon fiber, offering improved mechanical properties over pure PA610. It provides enhanced stiffness, strength, and wear resistance while maintaining good processability and flexibility. Ideal for light-duty automotive, industrial, and consumer goods applications, PA610-CF5 balances performance and durability in moderate environments.

Learn More

Carbon Fiber Nylon 610 Raw PA610 CF Plastic Mat...

PA610 CF plastic materials, with their composition and properties, are widely used in various industries like automotive, aerospace, electronics, and mechanical engineering.

Learn More

PA610 CF5 Nylon 610 5% Carbon Fiber Combinations

PA610 CF5 composites combine nylon 610 with 5% carbon fiber, offering enhanced mechanical strength, lightweight design, and chemical resistance. They find applications in automotive, aerospace, and industrial sectors requiring durable and reliable materials.

Learn More

Conductive PA610 CF60 Compounds Factory Price

Conductive PA610 CF60 composites combine the benefits of polyamide 610 with 60% carbon fiber reinforcement, making them ideal for demanding applications across automotive, aerospace, electronics, and industrial sectors where electrical conductivity, mechanical strength, and lightweight design are essential requirements.

Learn More

High Quality PA610 CF50 For Automotive Parts

PA610 CF50 composites combine polyamide 610 with 50% carbon fiber, offering high strength, stiffness, and heat resistance. They find applications in automotive components, aerospace parts, and industrial machinery where lightweight and durable materials are essential for performance and efficiency.

Learn More

High Quality PA610 CF40 at Competitive Prices

PA610 CF40 compounds are blends of polyamide 610 (PA610) reinforced with 40% carbon fiber. They provide enhanced mechanical properties such as strength, stiffness, and dimensional stability for industrial use.

Learn MoreProduct Feature Box

WEAR RESISTANCE

CONDUCTIVE MATERIALS

HIGH STRENGTH

SCRATCH RESISTANCE

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

ANTI STATIC

Company Advantage

Advanced Production Technology

Carbon (Xiamen) New Material is equipped with state-of-the-art carbon fiber composite production processes and advanced equipment. It has highly automated layup devices for precise fiber control, ensuring mechanical property consistency. Advanced curing methods like vacuum-assisted or autoclave curing improve efficiency and product quality. The company also regularly invests in research and development to introduce innovative production techniques, enhancing its ability to meet diverse customer needs and stay ahead in the competitive market.

Stringent Quality Control System

Carbon (Xiamen) New Material has a comprehensive quality inspection process in place, from raw material selection to finished product delivery. In raw material procurement, high-precision tests are done. During production, each step is monitored and sampled. Non-destructive testing checks for defects in finished products. This meticulous approach, coupled with continuous improvement efforts based on quality data analysis, ensures that every product leaving the factory meets or exceeds the most stringent industry standards.

Customization Production Capacity

Carbon (Xiamen) New Material is flexible and can meet unique customer demands. For aerospace, it uses advanced design and simulation for complex, high-performance parts. For the automotive industry, it combines strength with aesthetic and surface treatment. By closely collaborating with customers at every stage of the production process and leveraging its technical expertise, the company ensures that the final product precisely aligns with the customer's specifications and expectations.

Export Qualifications and Certifications

Carbon (Xiamen) New Material has export qualifications and international certifications like ISO 9001 and AS9100. These boost product recognition and competitiveness, opening doors to high-end markets and various industries. It is constantly working towards obtaining additional certifications and adhering to the latest industry standards to expand its market presence and meet the evolving demands of global customers.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What is Carbon Fiber Reinforced PA610 Composite?

Carbon Fiber Reinforced PA610 Composite is a type of carbon fiber reinforced PA610 thermoplastic composite. It combines the properties of PA610 with the reinforcing effect of carbon fibers to offer enhanced mechanical, thermal, and physical properties.

-

How does PA610 Carbon Fiber-Reinforced Material differ from regular PA610?

The addition of carbon fibers in PA610 Carbon Fiber-Reinforced Material significantly increases its strength, stiffness, and heat resistance compared to plain PA610. It also provides better dimensional stability and fatigue resistance.

-

What are the main advantages of using PA610 Reinforced with Carbon Fiber?

The main advantages include high strength-to-weight ratio, excellent mechanical performance, good chemical resistance, and the ability to be processed using various manufacturing techniques. It also offers design flexibility and can replace heavier metal components in many applications.

-

In which industries is Carbon Fiber-Enhanced PA610 commonly used?

Carbon Fiber-Enhanced PA610 is widely used in aerospace, automotive, sports equipment, medical devices, and industrial machinery. For example, it can be found in aircraft components, car parts, sports gear, and specialized medical equipment.

-

How is PA610 Composite Reinforced by Carbon Fiber processed?

It can be processed through methods such as injection molding, extrusion, and compression molding. These processes allow for the creation of complex shapes and components with precise dimensions.

-

What factors should be considered when selecting Carbon Fiber Strengthened PA610 for a specific application?

Factors like the required mechanical properties, operating environment (temperature, chemical exposure), part geometry, and manufacturing volume should be taken into account. Also, the cost and availability of the material are important considerations.

-

How does the cost of PA610 with Carbon Fiber Reinforcement compare to other materials?

PA610 with Carbon Fiber Reinforcement is generally more expensive than conventional plastics but can be cost-effective in applications where its superior properties lead to longer product life, reduced weight, or improved performance, outweighing the initial material cost.

-

Is Carbon Fiber Reinforced PA610 Composite recyclable?

While it is not as straightforward to recycle as some other materials, efforts are being made to develop recycling processes for Carbon Fiber Reinforced PA610 Composite to reduce its environmental impact. In some cases, it can be reprocessed within specific industrial recycling systems.