PA6 CF - Pushing Boundaries in Materials Science

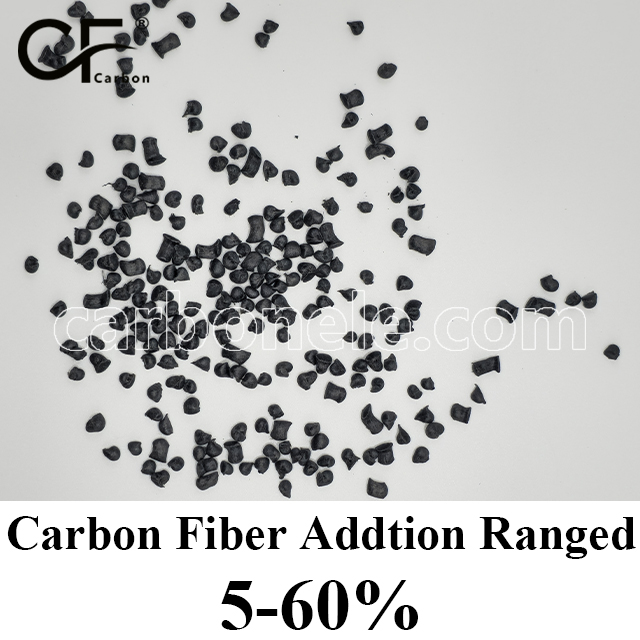

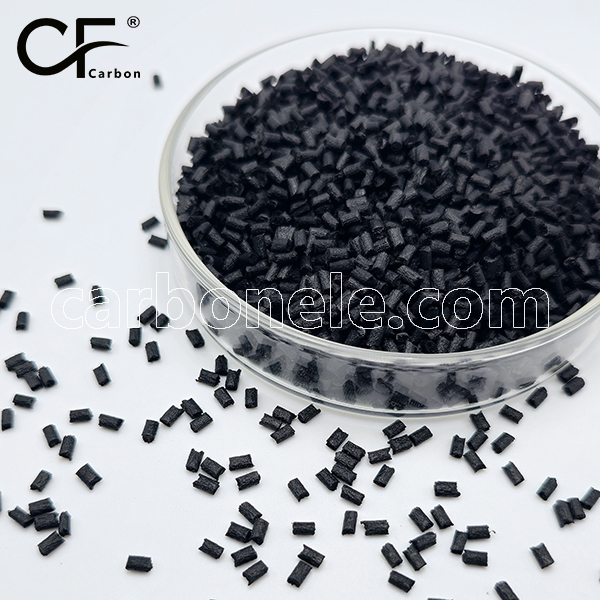

PA6 CF Reinforced Composites elegantly combine PA6 and carbon fibers. Polyamide 6 exhibits commendable mechanical properties. The integration of carbon fibers remarkably escalates tensile strength, modulus, and heat resistance. Moreover, it presents exceptional fatigue resistance, ensures excellent dimensional stability, and boasts low thermal expansion. All these traits make it highly suitable for diverse demanding applications.

Ideal for the aerospace industry where lightweight and high strength are crucial for fuel efficiency and performance. In the automotive sector, it helps improve vehicle efficiency and safety. The sports field benefits from it too, enhancing equipment durability and performance. However, the manufacturing process of PA6 CF Reinforced Composites is complex. It requires advanced techniques and precise control, leading to high production costs. Also, it has anisotropic properties, meaning its properties vary depending on the direction, which requires careful design and engineering. Despite these challenges, it remains a high-performance material, well-suited for demanding applications that demand superior mechanical and thermal properties.

Product By Features

PA6-CF20 composite materials

PA6-CF20 is a high performance PA6 composite reinforced with 20% carbon fiber, offering significantly enhanced strength, stiffness, and dimensional stability. It provides excellent wear resistance, reduced moisture absorption, and improved thermal performance, making it ideal for demanding industrial and automotive applications.

Learn More

PA6-CF10 Carbon fiber reinforced PA6

PA6-CF10 is a carbon fiber reinforced polyamide 6 with 10% carbon fiber, offering enhanced strength, stiffness, and wear resistance compared to standard PA6. It features improved dimensional stability, lower moisture absorption, and higher thermal resistance, making it ideal for structural, automotive, and industrial applications requiring increased mechanical performance and durability.

Learn More

High Strength Lightweight CF30 PA6 Pellets for ...

CF30 PA6 Pellets (30% carbon fiber reinforced nylon 6 pellets) are particularly well-suited for robotic 3D printing due to their high strength, lightweight properties, heat resistance, and print compatibility.

Learn More

High Strength CF30 PA6 Compounds for Robots

CF30 PA6 Compounds are ideal for applications requiring metal-like performance + polymer processing flexibility, redefining lightweight design paradigms for next-gen robotics.

Learn More

High Strength-to-weight Ratio PA6-CF Materials ...

PA6-CF materials are widely used in robotics due to its high strength, lightweight, fatigue resistance, and chemical stability, with key applications including Robotic Arms & Joint Components and Robot Housings & Structural Parts, etc.

Learn More

PA CF Compounds PA-CF-BCA as Shoe Materials

PA CF is widely used in the footwear industry due to its high strength, lightweight, wear resistance, and elasticity, particularly in high-performance sports shoes and functional footwear.

Learn More

PA6-CF5 Wear resistant engineering plastics

PA6-CF5 is a carbon fiber-reinforced polyamide 6 with 5% carbon fiber, offering improved strength, stiffness, and wear resistance compared to standard PA6. It features lower moisture absorption, enhanced dimensional stability, and better thermal resistance, making it ideal for lightweight structural, automotive, and industrial applications requiring moderate reinforcement and durability.

Learn More

High Strength PA6 CF30 Pellet Materials for Art...

High Strength PA6 CF30 Pellet Materials feature high tensile strength, excellent impact resistance, good chemical resistance, high rigidity, low friction coefficient, good thermal stability and dimensional stability for reliable performance.

Learn More

Carbon Fiber Modified Thermoplastics Nylon PA6-...

Nylon PA6-CF30, reinforced with 30% carbon fiber, offers exceptional tensile strength, lightweight properties, enhanced stiffness, heat and wear resistance, dimensional stability, and chemical resistance, making it ideal for high-performance structural and industrial applications.

Learn More

Wear Resistant Polymers PA6 CF30 PTFE Pellets

PA6 CF30 PTFE Pellets feature high wear & chemical stability, enhanced strength, low friction, good toughness, dimensional stability, and easy processability.

Learn More

Electric-conducting Materials PA6 CF30 Pellets ...

PA6 CF30 pellets feature good electrical conductivity for stable auto – part current transmission, high strength and rigidity for durability and shape – maintenance, wear and chemical corrosion resistance, good dimensional and thermal stability, and easy processability.

Learn More

Virgin High Strength PA6 CF30 Raw Materials for...

PA6 CF30 raw materials feature high strength for armrest durability against external forces, high purity for stable performance, good rigidity to resist deformation, excellent wear resistance to extend lifespan, easy processability for shaping, and good chemical stability against car – common chemicals.

Learn MoreProduct Feature Box

WEAR RESISTANCE

CONDUCTIVE MATERIALS

HIGH STRENGTH

ANTI STATIC

SCRATCH RESISTANCE

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

Company Advantage

Skilled and Motivated Workforce

Talented employees with expertise and a passion for their work can drive productivity and innovation. Google is known for attracting top talent.

Adaptive and Agile Culture

Quickly respond to changes in the market and adapt its strategies and operations is more likely to succeed. Netflix has demonstrated this ability in the evolving media landscape.

Strategic Partnerships and Alliances

Collaborating with other businesses can provide access to new technologies, markets, or resources. Microsoft's partnerships in the cloud computing space have strengthened its position.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What are the main advantages of PA6 CF Reinforced Composites?

They offer high tensile strength, improved heat resistance, and excellent fatigue resistance. Also, they provide good dimensional stability and low weight compared to traditional materials.

-

How is the durability of PA6 CF Reinforced Composites in harsh environments?

These composites have excellent resistance to chemicals, moisture, and temperature variations, making them suitable for use in various harsh conditions.

-

Can PA6 CF Reinforced Composites be machined easily?

While they can be machined, it requires specialized tools and techniques due to their high strength and hardness.

-

What is the typical cost range of PA6 CF Reinforced Composites?

The cost varies depending on factors such as the quality, quantity, and specific properties required. Generally, it is higher than common materials, but the performance justifies the expense in many applications.

-

Are there any limitations to the use of PA6 CF Reinforced Composites?

Their complex manufacturing process and higher cost can be limiting factors. Also, their anisotropic properties need to be considered in design.

-

How does the addition of carbon fibers affect the electrical conductivity of PA6?

The carbon fibers can increase the electrical conductivity to some extent, but it depends on the fiber content and orientation.

-

What kind of surface treatments are available for PA6 CF Reinforced Composites?

Common surface treatments include painting, coating, and plasma treatment to enhance adhesion, corrosion resistance, or aesthetic appearance.

-

How do the mechanical properties of PA6 CF Reinforced Composites change with temperature?

The mechanical properties remain relatively stable over a wide temperature range, but they may start to degrade at extremely high temperatures.