Transforming Industries through Advanced Nylon CF

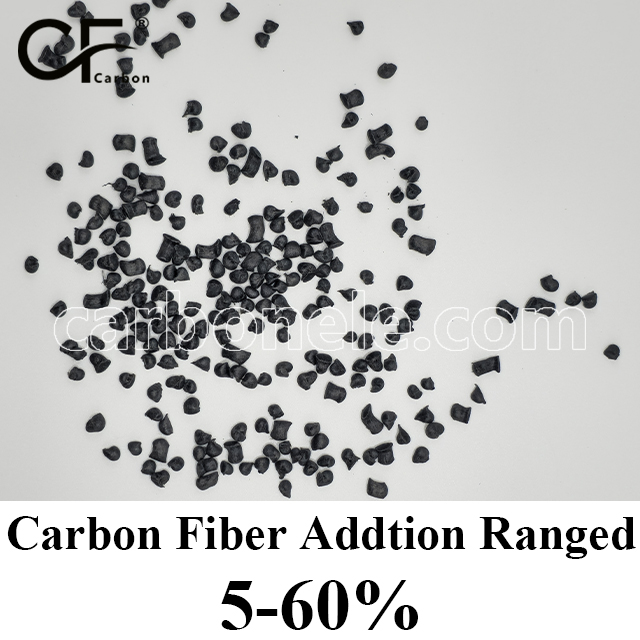

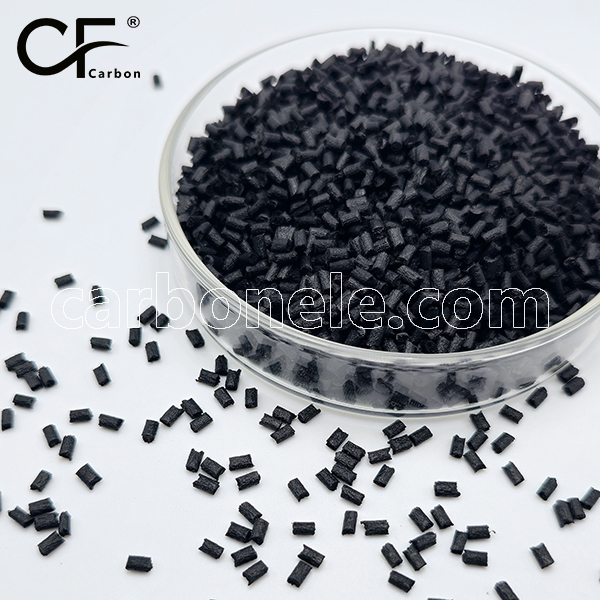

Carbon fiber reinforced nylon composite material refers to a modified composite material prepared by a certain production process with nylon as the base material and carbon fiber as the filler. This material has excellent properties such as high strength, high hardness, light weight, wear resistance, conductivity, anti-static property, etc., and is widely used in aerospace, military equipment, rail vehicles, automotive industry, household goods and other fields.

Nylon CF Reinforced Composites have several common application areas. They are widely used in the automotive industry for manufacturing parts like engine covers and gears due to their high strength and heat resistance. In the aerospace field, they can be found in structural components for lightweight and durability. They are also employed in the production of sports equipment, such as tennis rackets and bicycle frames, where strength and weight reduction are essential. Additionally, they are utilized in the manufacturing of industrial machinery parts for enhanced performance and longevity.

Product By Features

PA6-CF20 composite materials

PA6-CF20 is a high performance PA6 composite reinforced with 20% carbon fiber, offering significantly enhanced strength, stiffness, and dimensional stability. It provides excellent wear resistance, reduced moisture absorption, and improved thermal performance, making it ideal for demanding industrial and automotive applications.

Learn More

PA6-CF10 Carbon fiber reinforced PA6

PA6-CF10 is a carbon fiber reinforced polyamide 6 with 10% carbon fiber, offering enhanced strength, stiffness, and wear resistance compared to standard PA6. It features improved dimensional stability, lower moisture absorption, and higher thermal resistance, making it ideal for structural, automotive, and industrial applications requiring increased mechanical performance and durability.

Learn More

High Strength Lightweight CF30 PA6 Pellets for ...

CF30 PA6 Pellets (30% carbon fiber reinforced nylon 6 pellets) are particularly well-suited for robotic 3D printing due to their high strength, lightweight properties, heat resistance, and print compatibility.

Learn More

High Strength yet Lightweight PA66 CF40 Compoun...

PA66 CF40 compounds offer the best balance of strength, weight, and cost while enabling complex geometries for mass production and through the synergy of material science and engineering design, has become the gold standard for high-performance drone propellers and UAV blades.

Learn More

High Strength-to-weight Ratio CF40 PA66 for Agr...

CF40 PA66 is the Optimal Material for Drone Blades: ✅ High strength-to-weight ratio (close to metal, 45% lighter) → Longer flight time & higher payload. ✅ Fatigue & chemical resistance → Ideal for intensive farming operations. ✅ High stiffness & low vibration → Stable flight, fewer failures. ✅ Injection molding…

Learn More

High Strength CF30 PA6 Compounds for Robots

CF30 PA6 Compounds are ideal for applications requiring metal-like performance + polymer processing flexibility, redefining lightweight design paradigms for next-gen robotics.

Learn More

High Strength-to-weight Ratio PA6-CF Materials ...

PA6-CF materials are widely used in robotics due to its high strength, lightweight, fatigue resistance, and chemical stability, with key applications including Robotic Arms & Joint Components and Robot Housings & Structural Parts, etc.

Learn More

PA CF Compounds PA-CF-BCA as Shoe Materials

PA CF is widely used in the footwear industry due to its high strength, lightweight, wear resistance, and elasticity, particularly in high-performance sports shoes and functional footwear.

Learn More

Conductive PAMXD6 CF30 Plastic Raw Materials fo...

Conductive PAMXD6 CF30 is a carbon fiber-reinforced polyamide composite offering high electrical conductivity (10²–10⁵ Ω/sq), exceptional strength (>200 MPa), heat resistance (>200°C), low moisture absorption (<1%), chemical resistance, and lightweight wear resistance.

Learn More

PA6-CF5 Wear resistant engineering plastics

PA6-CF5 is a carbon fiber-reinforced polyamide 6 with 5% carbon fiber, offering improved strength, stiffness, and wear resistance compared to standard PA6. It features lower moisture absorption, enhanced dimensional stability, and better thermal resistance, making it ideal for lightweight structural, automotive, and industrial applications requiring moderate reinforcement and durability.

Learn More

High stress applications MXD6-CF60

MXD6-CF60 is a high-performance polyamide composite reinforced with 60% carbon fiber, providing maximum strength, stiffness, wear resistance, and thermal stability. With a heat deflection temperature of ~360°C, very low moisture absorption, and excellent chemical resistance, it is ideal for automotive, industrial, and extreme engineering applications. Suitable for injection molding and…

Learn More

MXD6-CF50 high stress applications

MXD6-CF50 is a high performance polyamide composite reinforced with 50% carbon fiber, delivering maximum strength, stiffness, wear resistance, and thermal stability. With a heat deflection temperature of ~340°C, very low moisture absorption, and excellent chemical resistance, it is ideal for automotive, industrial, and extreme engineering applications. Suitable for injection molding…

Learn MoreProduct Feature Box

WEAR RESISTANCE

HIGH STRENGTH

LIGHT WEIGHT

SCRATCH RESISTANCE

ABRASION RESISTANCE

CONDUCTIVE MATERIALS

ANTI STATIC

ECO FRIENDLY

Exceptional Traits of CF Nylon Composites

1. Exceptional mechanical properties

It has high strength and hardness, capable of withstanding large loads and stresses.

2. Lightweight

Compared to traditional materials, it is lighter, helping to reduce the weight of the overall structure, which is of great significance in fields such as aerospace and automotive.

3. Good wear resistance

This enables it to perform well in components with frequent friction, prolonging the service life of the product.

4. Outstanding thermal stability

It can maintain stable performance in high-temperature environments and is suitable for high-temperature working components such as engines.

5. Conductivity and antistatic properties

This feature can prevent the accumulation of static electricity in the electronic and electrical fields, ensuring the safe operation of equipment.

6. Chemical resistance

It can resist the erosion of various chemicals and adapt to different working environments.

7. Design flexibility

It can be customized in shape and size according to specific needs to meet complex design requirements.

8. Cost-effectiveness

Although the initial cost may be higher, due to its long service life and high performance, it is cost-effective in the long run.

For example, in the aerospace field, its lightweight and high-strength characteristics help reduce the fuel consumption of aircraft. In electronic devices, conductivity and antistatic properties ensure the normal operation of the equipment without being affected by static electricity interference.

Company Advantage

Excellent After-sales Service

Carbon (Xiamen) New Material offers all-round, prompt, and professional after-sales support. A dedicated team responds within 24 hours. They solve problems remotely or on-site and provide installation and maintenance training. Feedback is used to improve service. The company also establishes long-term relationships with customers by providing regular maintenance checks and updates, ensuring the longevity and optimal performance of its products.

Stringent Quality Control System

Carbon (Xiamen) New Material has a comprehensive quality inspection process in place, from raw material selection to finished product delivery. In raw material procurement, high-precision tests are done. During production, each step is monitored and sampled. Non-destructive testing checks for defects in finished products. This meticulous approach, coupled with continuous improvement efforts based on quality data analysis, ensures that every product leaving the factory meets or exceeds the most stringent industry standards.

Modern Factory Facilities

In modern factory facilities, carbon fiber-reinforced thermoplastic composites are becoming increasingly important. They are precisely manufactured on highly automated production lines, combining the advantages of carbon fibers and thermoplastics. With strict quality checks and continuous R&D, they are delivered efficiently to customers worldwide, facilitating industrial development.

Advanced Laboratory Equipment

1. Performance Testing Equipment Equipped with universal material testing machines, dynamic mechanical analyzers (DMA), thermogravimetric analyzers (TGA), differential scanning calorimeters (DSC), thermal conductivity testers, electrical property testers, etc., to comprehensively evaluate various properties of the materials. 2. Microstructure Analysis Instruments Including scanning electron microscopes (SEM), transmission electron microscopes (TEM), X-ray diffraction analyzers (XRD), etc., for observing and analyzing the microstructure and phase distribution of the materials.

Customization Production Capacity

Carbon (Xiamen) New Material is flexible and can meet unique customer demands. For aerospace, it uses advanced design and simulation for complex, high-performance parts. For the automotive industry, it combines strength with aesthetic and surface treatment. By closely collaborating with customers at every stage of the production process and leveraging its technical expertise, the company ensures that the final product precisely aligns with the customer's specifications and expectations.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

FAQ 1: What are the key properties of Nylon Fiber-Reinforced Composites?

Answer: These composites typically exhibit increased strength, stiffness, and improved heat resistance compared to plain nylon.

-

FAQ 2: How are Nylon Carbon Fiber Reinforced Materials manufactured?

Answer: They are usually produced through processes such as injection molding or extrusion, where carbon fibers are incorporated into the nylon matrix.

-

FAQ 3: In what applications are Nylon Fiber-Reinforced Composites commonly utilized?

Answer: They are frequently found in automotive components, aerospace parts, and industrial machinery due to their high performance.

-

FAQ 4: What are the advantages of using Nylon Carbon Fiber Reinforced Materials over traditional metals?

Answer: They offer weight reduction, better corrosion resistance, and design flexibility.

-

FAQ 5: How does the cost of Nylon Fiber-Reinforced Composites compare to other composites?

Answer: The cost can vary depending on the specific formulation and manufacturing process, but it may be higher than some common composites.

-

FAQ 6: Are Nylon Carbon Fiber Reinforced Materials recyclable?

Answer: To some extent, but the recycling process can be challenging and may not be as straightforward as for some other materials.

-

FAQ 7: What kind of maintenance is required for products made from Nylon Fiber-Reinforced Composites?

Answer: Generally, minimal maintenance is needed. Regular cleaning and inspection for damage are often sufficient.

-

FAQ 8: Can the properties of Nylon Carbon Fiber Reinforced Materials be customized?

Answer: Yes, by adjusting the composition and processing parameters, the properties can be tailored to specific requirements.

-

FAQ 9: How do environmental factors affect the performance of Nylon Fiber-Reinforced Composites?

Answer: Exposure to extreme temperatures, humidity, and UV radiation can have an impact, but they are designed to withstand certain environmental conditions.

-

FAQ 10: What are the latest trends in the development of Nylon Carbon Fiber Reinforced Materials?

Answer: Current trends include the development of more efficient manufacturing methods, improved fiber-matrix adhesion, and enhanced material performance.