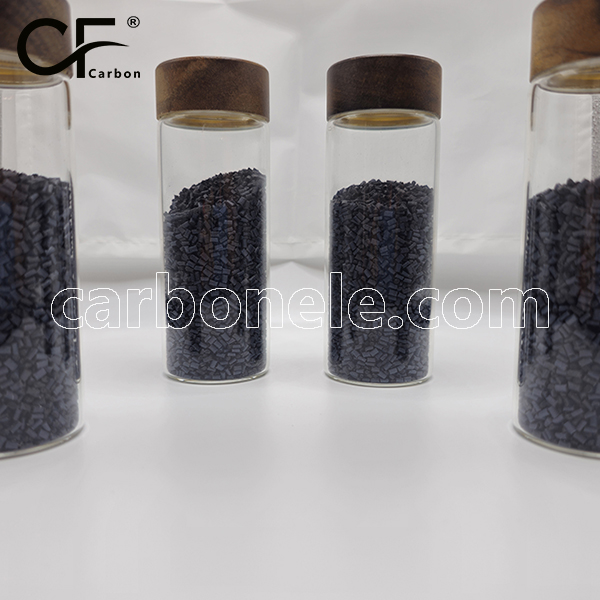

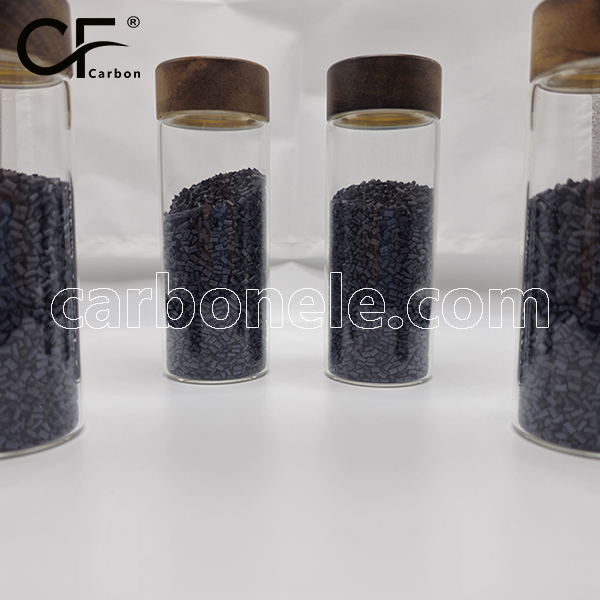

PPS Carbon Fiber Reinforced Composites

The process flow of PPS CF Reinforced Composites typically involves several steps. First, the PPS resin and carbon fibers are carefully selected and prepared. Then, they are mixed thoroughly using specialized equipment to ensure uniform distribution. Next, the mixture is heated and molded under high pressure to form the desired shape. Finally, the composites undergo post-processing for surface treatment and quality control. The main characteristics of PPS CF Reinforced Composites include high strength and stiffness, excellent heat resistance, good chemical resistance, and low moisture absorption. These properties make them suitable for applications in harsh environments and where high mechanical performance is required.

In which fields are PPS CF Reinforced Composites mainly applied? PPS CF Reinforced Composites are mainly applied in the following fields: In the aerospace field, they are used to manufacture structural components of aircraft, such as some components of wings and fuselages, due to their high strength and high-temperature resistance. In the automotive industry, they can be used to make parts around the engine, transmission system components, etc., which helps reduce the weight of vehicles and improve performance. In the electronic field, they can be used to make high-demanding electronic component housings and heat sinks, with good heat resistance and electrical insulation. In industrial machinery, they are used to manufacture parts that bear heavy loads and high-temperature environments, such as gears and bearings. In addition, they are also applied in sports goods, such as high-performance bicycle parts and sports equipment.

Product By Features

High Wear Resistance CF30 PPS Pellets for Rack ...

High Wear Resistance CF30 PPS Pellets are a high-performance composite materi...

Learn More

High Dimensional Stability CaCo3 Filled PPS CF ...

The material consists of PPS with thermal, chemical & mechanical merits, CaCo3 filler for dimensional stability, and CF which boosts tensile, stiffness & impact resistance, each playing a crucial role.

Learn More

High Strength Talc Filled PPS CF Pellets PPS-CF...

High Strength Talc Filled PPS CF Pellets combine PPS, CF and talc. CF boosts strength for heavy loads, talc improves stability and flow. Widely used in electronics, automotive etc., it’s a great engineering choice.

Learn More

High Wear Resistant PPS-CF-MoS2 Pellets

High Wear Resistant PPS-CF-MoS2 Pellets, combining PPS with CF and MoS2, have enhanced properties like strength, wear resistance and thermal stability, thus being widely used in various industries.

Learn More

Glass Beads Filled PPS CF 10 Composites

Glass Beads Filled PPS CF 10, with PPS as the base, 10% CF and glass beads as reinforcements, combines unique properties and finds use in automotive, electronics and industrial fields for balanced performance.

Learn More

High Temp Resistance PPS GF/CF Pellets

High Temp Resistance PPS GF/CF Pellets: With PPS as matrix, added GF and CF. PPS has good high-temp, chemical stability and mechanical properties. The composite works well in high-temp scenarios, with broad prospects.

Learn More

Carbon Fiber Filled PPS-CF 20 Pellet 25 Kg Price

PPS-CF 20 Pellet, a high-performance composite with PPS as matrix resin and 20% CF for enhancement, has good properties and is favored in electronics, automotive and aerospace fields.

Learn More

High-Strength PPS-LCF10 Composite Materials

PPS-LCF10 is a carbon fiber-reinforced polyphenylene sulfide with 10% carbon fiber. It offers good strength, rigidity, and thermal stability, making it suitable for moderate-load industrial applications. The material has excellent chemical resistance, high-temperature performance, and low water absorption, ideal for automotive, manufacturing, electronics, and aerospace uses. It also features improved…

Learn More

High-Strength PPS-CF60 Composite Materials

PPS-CF60 is a high-performance plastic with 60% carbon fiber, offering excellent strength, stiffness, and dimensional stability. It performs well under high loads, extreme temperatures, and aggressive chemicals. Ideal for demanding applications in automotive, aerospace, and industrial sectors, it provides outstanding wear resistance and thermal stability.

Learn More

Pinnacle High-Strength PPS-CF50 Composite Mater...

PPS-CF50 (Polyphenylene Sulfide with 50% Carbon Fiber) is a high-performance material offering exceptional strength, stiffness, and chemical resistance. With a 50% carbon fiber reinforcement, it excels in high-load, high-stress environments, providing superior wear resistance and thermal stability. Ideal for automotive, aerospace, and industrial applications, it performs well under extreme temperatures…

Learn More

The Pinnacle of High-Strength Composite Materia...

PPS-CF40 is a high-performance plastic reinforced with 40% carbon fiber, offering exceptional strength, stiffness, and thermal stability (up to 280°C). It resists harsh chemicals and wear, making it ideal for high-load applications in industries like automotive, aerospace, and manufacturing.

Learn More

PPS-CF30: The Pinnacle of High-Strength Composi...

PPS-CF30 is a high performance plastic reinforced with 30% carbon fiber, offering exceptional strength, stiffness, and thermal stability. With a tensile strength of ≥ 180 MPa and a heat deflection temperature of ~320°C, it excels in demanding applications in automotive, aerospace, and industrial sectors, providing superior chemical resistance and wear…

Learn MoreProduct Feature Box

WEAR RESISTANCE

CONDUCTIVE MATERIALS

HIGH STRENGTH

ANTI STATIC

SCRATCH RESISTANCE

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

Company Advantage

Rich Industry Experience

Years of involvement give Carbon (Xiamen) New Material production and trade knowledge. It supplies to major projects, enhancing skills and reputation. Active in global events, it keeps up with trends and gains information for growth. By leveraging this experience, the company is able to anticipate market shifts and proactively adjust its strategies and product offerings to stay relevant and competitive.

Export Qualifications and Certifications

Carbon (Xiamen) New Material has export qualifications and international certifications like ISO 9001 and AS9100. These boost product recognition and competitiveness, opening doors to high-end markets and various industries. It is constantly working towards obtaining additional certifications and adhering to the latest industry standards to expand its market presence and meet the evolving demands of global customers.

Excellent After-sales Service

Carbon (Xiamen) New Material offers all-round, prompt, and professional after-sales support. A dedicated team responds within 24 hours. They solve problems remotely or on-site and provide installation and maintenance training. Feedback is used to improve service. The company also establishes long-term relationships with customers by providing regular maintenance checks and updates, ensuring the longevity and optimal performance of its products.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What is the maximum temperature that PPS CF Reinforced Composites can withstand?

PPS CF Reinforced Composites can typically withstand temperatures up to around 260°C.

-

How does the addition of carbon fibers improve the properties of PPS?

Carbon fibers enhance the strength, stiffness, and thermal conductivity of PPS, making the composites more suitable for demanding applications.

-

Are PPS CF Reinforced Composites electrically conductive?

Depending on the carbon fiber content and distribution, they can have varying degrees of electrical conductivity.

-

Can PPS CF Reinforced Composites be recycled?

The recyclability of PPS CF Reinforced Composites is a complex issue. While it is possible to recycle them to some extent, it presents certain challenges. The difficulty lies in the separation of the PPS resin and carbon fibers during the recycling process. However, some advanced recycling technologies and methods are being developed and explored to improve the recyclability of these composites. In some cases, they can be reprocessed and reused in applications where the performance requirements are not as stringent. But achieving a high level of efficient and sustainable recycling is still an area that requires further research and innovation.