Unveiling the Potential of ABS CF Reinforced Composites

ABS CF (Acrylonitrile Butadiene Styrene with Carbon Fiber) reinforced composites integrate the advantages of ABS plastic and the strength and rigidity of carbon fiber, creating a material with improved mechanical attributes and durability. ABS CF reinforced composites present a persuasive combination of enhanced mechanical properties and flexibility, making them suitable for a wide array of challenging applications across diverse industries. With technological progress, their usage is likely to increase further, driven by the demand for lightweight, strong, and durable materials in modern manufacturing.

Main features: 1. Incorporating carbon fiber boosts ABS's strength and rigidity, ideal for firmness-demanding applications. 2. Remains lightweight compared to metals, beneficial for weight reduction. 3. Enhances dimensional stability, minimizing distortion for precise manufacturing. 4. Shows better heat resistance than standard ABS. 5. Has a smoother and more appealing surface finish. Applications: Used in automotive, aerospace, consumer goods, industrial equipment, and prototyping/tooling for its properties.

Product By Features

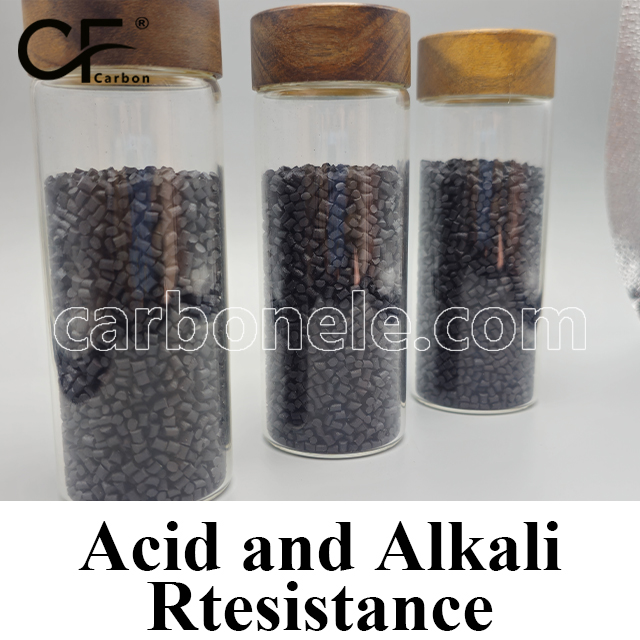

Carbon-fiber Reinforced Polymers CF30-ABS Plast...

CF30-ABS plastic raw materials feature 30% carbon fiber reinforcement for high strength, are lightweight, have good impact resistance from ABS, excellent thermal stability, chemical resistance, high rigidity, dimensional stability, and are easily moldable.

Learn More

Carbon Fiber Reinforced Thermoplastics CF30 ABS...

CF30 ABS is a material featuring high strength from carbon fiber reinforcement, good thermal stability, 30% carbon fiber for rigidity, excellent impact resistance from ABS, lightweight nature, chemical resistance, easy processability, and dimensional stability.

Learn More

Lightweight Durable ABS CF60 Materials for Dron...

Lightweight Durable ABS CF60 Materials feature 60% carbon fiber for high strength, enhanced rigidity, wear resistance, thermal stability, low expansion, conductivity, and are easy to process.

Learn More

ABS CF50 Plastic Raw Material Pellets for UAV C...

ABS CF50 plastic raw material pellets feature high strength from 50% carbon fiber, enhanced rigidity, good wear resistance, excellent thermal stability, low thermal expansion, some electrical conductivity, are lightweight and easy to process for UAV control boards.

Learn More

High-impact ABS CF40 Plastic Pellets for Drone ...

High-impact ABS CF40 plastic pellets, with 40% carbon fiber providing high strength for tough applications, offer enhanced rigidity, excellent wear resistance, good thermal stability, low thermal expansion, some electrical conductivity, are lightweight, and are easily processed by common methods.

Learn More

High Strength ABS CF30 Raw Material Pellets for...

ABS CF30 raw material pellets feature high strength for heavy loads, 30% carbon fiber for rigidity and dimensional stability, good wear resistance, excellent thermal stability, low thermal expansion, some electrical conductivity, and easy processing for efficient production.

Learn More

ABS-CF60 Impact Protection

ABS-CF60 is a high performance composite material with 60% carbon fiber reinforcement, offering exceptional stiffness, strength, and wear resistance. Ideal for extreme mechanical loads and severe stress conditions, it excels in high temperature and chemically aggressive environments. ABS-CF60 is perfect for applications in automotive, industrial manufacturing, electronics, and consumer goods,…

Learn More

Impact Protection ABS-CF50

ABS-CF50 is a high performance carbon fiber reinforced material, offering exceptional strength, wear resistance, and thermal stability. With 50% carbon fiber content, it excels in extreme conditions, making it ideal for demanding applications in automotive, industrial, and electronics industries. Its superior durability and impact protection ensure long-lasting performance in high-load,…

Learn More

Carbon Fiber Components Tailored ABS-CF40

ABS-CF40, with 40% carbon fiber reinforcement, offers unparalleled strength, wear resistance, and impact protection. It excels in high-temperature and chemically aggressive environments, making it ideal for heavy-duty automotive, industrial, and electronic applications. With low moisture absorption and excellent dimensional stability, it ensures reliable performance in the harshest conditions.

Learn More

Tailored Carbon Fiber Components ABS-CF30

ABS-CF30, with 30% carbon fiber reinforcement, delivers exceptional strength, wear resistance, and impact protection. It performs well under extreme temperatures and chemical exposure, making it ideal for heavy-duty automotive, industrial, and electronic applications. With excellent dimensional stability and low moisture absorption, it offers superior durability in challenging environments.

Learn More

Tailored ABS-CF20 Carbon Fiber Components

ABS-CF20, with 20% carbon fiber reinforcement, offers exceptional strength, wear resistance, and impact protection. It performs well under high temperatures and chemical exposure, making it ideal for heavy-duty automotive, industrial, and electronics applications. It also boasts excellent dimensional stability, low moisture absorption, and is easy to process via injection molding…

Learn More

ABS-CF10 custom carbon fiber parts

ABS-CF10, with 10% carbon fiber, offers improved strength, wear resistance, and impact resistance compared to standard ABS. It performs well under moderate to high temperatures and chemical exposure, and is ideal for automotive, industrial, and consumer applications requiring higher durability. Easy to process via injection molding and extrusion.

Learn MoreProduct Feature Box

WEAR RESISTANCE

CONDUCTIVE MATERIALS

HIGH STRENGTH

ANTI STATIC

SCRATCH RESISTANCE

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

Company Advantage

Innovation-driven R & D capabilities

Our company is committed to continuous investment in research and development, fostering a team of highly skilled and creative experts. This enables us to stay at the forefront of industry trends and develop cutting-edge products and solutions that meet the evolving needs of the market.

Strong supply chain management

We have established strategic partnerships with reliable suppliers, ensuring a stable and efficient supply of high-quality raw materials. Our advanced inventory management system and logistics network minimize lead times and costs, providing a competitive edge in delivering products to customers promptly.

Exceptional customer service

Placing customers at the core of our business, we have built a dedicated customer service team that is available 24/7 to address inquiries and concerns. We strive to exceed customer expectations by providing personalized support, prompt responses, and effective solutions, thereby fostering long-term relationships based on trust and satisfaction.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How does the price of ABS CF Reinforced Composites compare to traditional materials?

The price of ABS CF Reinforced Composites is usually slightly higher than that of traditional materials because of its superior performance and the inclusion of reinforcing components such as carbon fiber. However, the specific price is affected by factors such as market supply and demand and production scale.

-

What level of strength can this material reach?

The strength of this material is significantly higher than that of ordinary ABS materials. The specific strength level depends on factors such as the content and distribution of carbon fiber and can generally meet the needs of various high-strength applications.

-

How is the corrosion resistance of ABS CF Reinforced Composites?

ABS CF Reinforced Composites have good corrosion resistance and can resist the erosion of various chemicals. However, the specific degree of corrosion resistance is also affected by factors such as the type and concentration of chemicals.

-

How does its performance behave in high-temperature environments?

It can still maintain good mechanical properties and dimensional stability in high-temperature environments. Compared to ordinary ABS materials, its high-temperature resistance performance has improved significantly.

-

How to process ABS CF Reinforced Composites?

Common processing methods include injection molding, extrusion molding, etc. During processing, adjustments need to be made according to specific process requirements and equipment conditions.

-

How to distinguish the quality of ABS CF Reinforced Composites?

To distinguish the quality, it can be judged from aspects such as the uniformity of the appearance, strength tests of the material, and checking relevant quality certifications.

-

How long is the service life of ABS CF Reinforced Composites approximately?

Its service life depends on factors such as the usage environment and load conditions. Under normal usage and maintenance conditions, it usually has a long service life.

-

Compared to other reinforced composites, what are its unique advantages?

Compared to other reinforced composites, it combines the good processing performance of ABS and the advantages of high strength and high rigidity brought by carbon fiber, and the cost is also relatively reasonable.

-

Where can I buy high-quality ABS CF Reinforced Composites?

High-quality materials can be purchased from professional composite material suppliers, large building material markets, or by directly contacting related manufacturers.

-

How is the environmental performance of this material?

This material is relatively environmentally friendly during production and use and can be recycled. However, relevant environmental standards and regulations still need to be followed for processing.