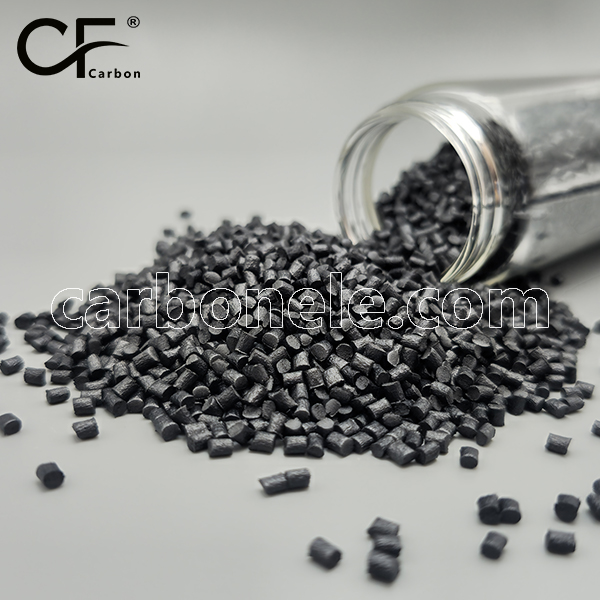

PETG CF Pellets for 3D Printing PETG-CF Filament

PETG CF Pellets for 3D Printing have multiple characteristics including good mechanical, thermal, chemical properties, unique appearance, easy processing and being lightweight, making them suitable for various applications.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model: PETG-CF-BCA3

- Fillers: Carbon fiber

PETG CF Pellets for 3D Printing PETG-CF Filament

Mechanical Properties

– High Strength: High tensile & flexural strength. E.g., Nanovia’s can reach 43 MPa (tensile) & 3800 MPa (flexural), better than ordinary PETG, for load-bearing parts.

– High Rigidity: Maintains shape well, suits precise parts.

– Good Impact Resistance: Withstands complex forces, good for mechanical parts.

Thermal Properties

– High Temperature Resistance: Has relatively high heat distortion temp., like Bambu Labs’ reaching 74 °C, usable in some heat.

– Low Shrinkage Rate: Small thermal shrinkage in printing, reduces warping, boosts accuracy.

Chemical Properties

– Corrosion Resistance: Tolerates many chemicals, not easily corroded, for complex chem. environments.

– Weather Resistance: Some UV resistance, okay for outdoors but may need extra protection for long-term.

Appearance and Texture

– Matte Finish: Prints have matte look, looks industrial, for special appearance parts.

– Color Options: Limited but has options like dark gray, etc., more than plain carbon fiber.

Processing Properties

– Easy Extrusion: Good fluidity, passes nozzle/mold smoothly, no clogging easily, smooth surface after.

– Strong Interlayer Adhesion: Layers bond firmly in printing, enhances strength & stability.

Lightweight

Low density due to carbon fiber, enables lightweight design, fits weight-sensitive fields like aerospace, automotive.

| Aspect | PETG CF Pellets for 3D Printing | Regular PETG Pellets |

|---|---|---|

| Composition | Contain carbon fiber | No carbon fiber |

| Mechanical Properties | Higher strength and stiffness, improved durability and dimensional stability | Relatively lower strength and less stiffness, normal durability and dimensional stability |

| Melting Behavior | Slightly different, may need adjusted processing temperatures for filament making or 3D printing | Normal melting behavior with standard processing temperature settings for common applications |

Table 1 Main characteristics of PETG CF Pellets for 3D Printing compared to regular PETG pellets

Question: How can PETG-CF Filament be produced from PETG CF Pellets for 3D Printing?

Answer: Generally, PETG-CF Filament can be produced through an extrusion process. First, the PETG CF Pellets are fed into an extruder, which heats the pellets to their melting point. Then, under the pressure generated by the extruder’s screw, the molten material is pushed through a die with a specific diameter to form a continuous filament. During this process, it’s crucial to control parameters such as the temperature profile along the extruder barrel, the screw speed to ensure consistent melting and proper flow of the material with carbon fiber evenly distributed within the filament, and finally, the cooling of the extruded filament to solidify it in the desired shape and diameter suitable for 3D printing.

Question: In which applications is PETG-CF Filament more preferred in 3D printing?

Answer: PETG-CF Filament is highly preferred in several 3D printing applications. For example, in the manufacturing of mechanical parts like gears, brackets, or tool handles, its enhanced strength and rigidity provided by the carbon fiber make it suitable to withstand mechanical stress and loads. It’s also favored for creating prototypes in industries such as automotive and aerospace where lightweight yet sturdy components are needed. Additionally, for artistic or decorative items that require a unique texture and good durability, the carbon fiber in the PETG-CF Filament can add an appealing visual effect while maintaining the structural integrity of the printed object.

Question: What challenges might one encounter when using PETG-CF Filament for 3D printing and how to solve them?

Answer: Some common challenges include clogging of the printer nozzle. Due to the presence of carbon fiber, the filament may not flow as smoothly as pure PETG, and if the printing temperature is not properly set or if there is debris in the nozzle, it can lead to blockages. To solve this, make sure to set an appropriate printing temperature within the recommended range for the specific PETG-CF Filament being used, usually a bit higher than that for regular PETG, and regularly clean the nozzle. Another challenge is layer adhesion. Sometimes the carbon fiber can affect how layers bond together. To improve layer adhesion, adjusting the printing speed to a proper level (slower than normal in some cases) and ensuring proper cooling settings can help, as well as making sure the printing bed is clean and has good adhesion promotion for the filament to stick well to it.

If you want more information on PETG CF pellets or more carbon fiber modified nylon materials, please click here.

Contact Us

If you want to obtain information such as product specifications, performance, and price, choose a suitable product according to your own needs. Meanwhile, you can ask the manufacturer to provide samples for testing to ensure that the material meets your usage requirements. If you are interested in purchasing this composite material, please contact the manufacturer Carbon (Xiamen) New Material directly.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.