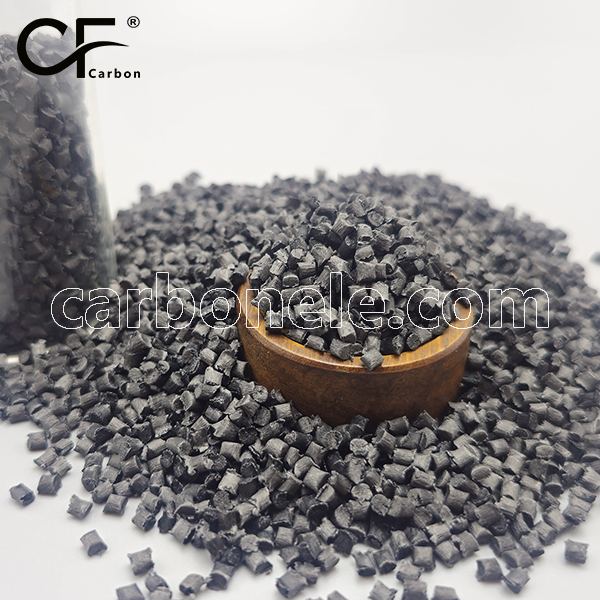

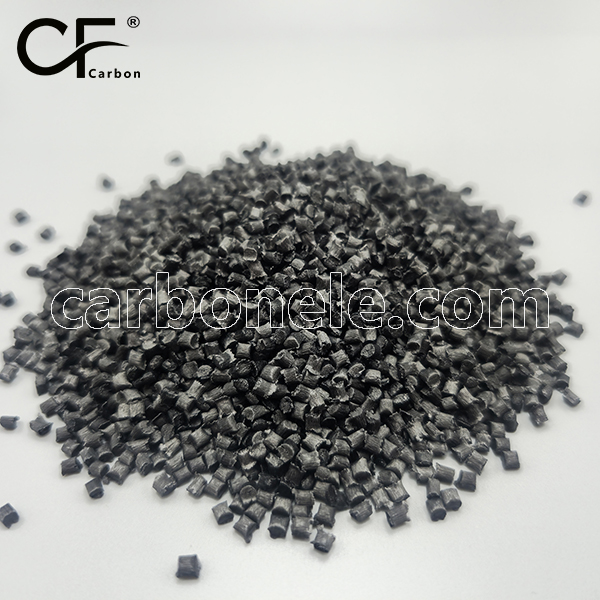

PC Carbon Fiber Polycarbonate Raw Materials for 3D Printing PC-CF Filaments

PC Carbon fiber composites offer excellent mechanical, physical and processing properties, along with environmental friendliness and aesthetics. PC CF is widely used in 3D printing filaments.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model : PC-CF-BCA4

Why to Choose PC Carbon Fiber raw materials as 3D printing filaments?

Carbon fiber reinforced polycarbonate (PC carbon fiber) has excellent mechanical properties, good physical properties, outstanding processing performance (good fluidity and compatibility), and other advantages.

1. Excellent mechanical properties:

– High strength: Carbon fiber boosts polycarbonate’s strength. Printed products can handle stress and load, suitable for high-strength parts like auto, mechanical, and tools.

– High stiffness: Enhances rigidity, reducing deformation for precise dimensions and stability.

– Good impact resistance: Higher than pure polycarbonate, resistant to external impacts for collision-prone applications.

2. Good physical properties:

– Light weight: Low density due to carbon fiber, important for aerospace to reduce weight and improve performance.

– Stable dimensions: Low thermal expansion for stable size in different temperatures, reducing deviations.

– Good wear resistance: Improves surface durability, suitable for wear-prone parts like gears and rails.

3. Outstanding processing performance:

– Good fluidity: Smoothly passes through nozzle for seamless printing, reducing clogging and breakage.

– Compatibility: Works with most 3D printers, no special modifications needed, lowering costs.

4. Other advantages:

– Environmental friendliness: Polycarbonate and carbon fiber are recyclable to some extent, meeting sustainable requirements.

– Aesthetics: Prints unique parts with black carbon fiber texture, adding tech and quality for high-appearance products.

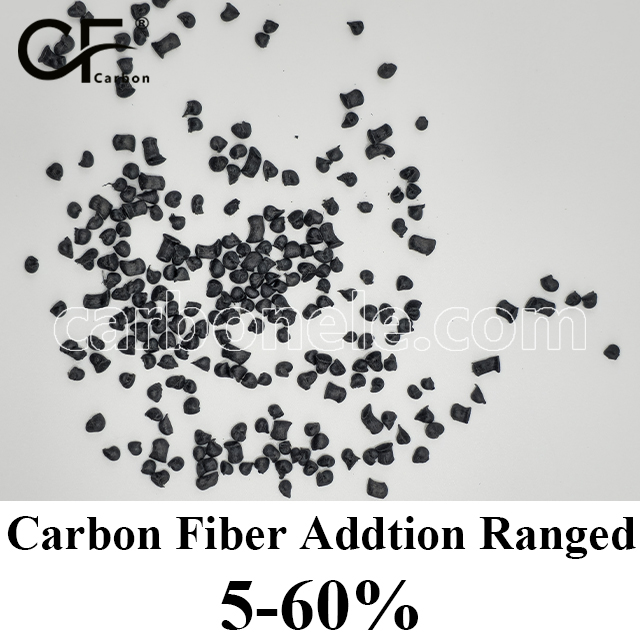

What types of carbon fiber reinforced PC raw materials are suitable for 3D printing filaments?

1. High proportion carbon fiber reinforced raw materials:

– PC-CF-BCA2: Containing 20% carbon fiber modified reinforcement, this material as PC carbon fiber raw materials exhibits outstanding performance in mechanical properties like strength and rigidity. It is ideal for manufacturing parts that have high structural strength requirements, such as the shells or internal structural components of laptops, OA equipment, and electrical appliances.

– PC-CF-BCA3: Boasting 30% carbon fiber reinforcement, the carbon fiber content is relatively high. This enables a further enhancement of the material’s strength and rigidity. It can be utilized to manufacture mechanical structural parts and drone parts that have extremely high material performance requirements. For instance, it is suitable for making the wings and fuselage structural parts of some high-performance drones.

2. PC CF raw materials with low shrinkage rate:

– PC-CF-BCA1: This is a product with good performance in shrinkage control. It is suitable for manufacturing electronic equipment shells and precision instrument parts with strict dimensional accuracy requirements. For example, it can be used to manufacture the fine shell structure of electronic devices such as mobile phones and tablets, as well as the shells and internal brackets of various precision instruments.

3. PC carbon fiber raw materials with good compatibility with common 3D printers:

– This type of product has been optimized in design. Its melting point, fluidity and other parameters can well adapt to the working conditions of most 3D FDM printers. For example, for some common desktop 3D FDM printers such as Creality Ender series and Anycubic series, these universal PC CF filaments can be printed smoothly without excessive adjustment and modification of the printer. The printing process is stable and there are no problems such as clogging and wire breakage. It can be used to print some small creative models and tool parts.

4. PC carbon fiber raw materials with good fluidity:

– PC CF filaments produced by this raw material has been improved in formulation and production process and has good fluidity. For models with complex structures and rich details, such as decorative items with fine internal hollow structures and industrial parts models with complex pipeline structures, this kind of filament can better fill tiny structures and gaps and print out more refined products.

If you want to obtain more information about PC carbon fiber raw materials or other carbon fiber reinforced composites, please contact us.

Contact Us

If you are interested then feel free to reach out for additional information or any other material information with any questions.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.