PA66 CF30 Reinforcement Compound Manufacturer

The density of PA66/CF composite material like pa66 cf30 is less than 1.3. Compared with the density of steel (7.85), it is less than one-sixth of its density, achieving the purpose of lightweight and conducive to energy saving and consumption reduction. As the CF content increases, the tensile strength and the flexural strength and flexural modulus of PA66 CF30 composite materials increase significantly.

- Matrix Resins: Nylon 66, polyamide 6.6, PA 66 6/6

- Molding Process: Injection, extrusion

- Filler: 30% carbon fibers

- Free Samples: 3-15kgs

- Manufacturer: Yes

- Model No.: PA66-CF-BCA3

What’re PA66 CF30 compounds?

PA66 CF30 is a polyamide 66 (nylon 66) product filled with 30% carbon fiber. Features include: conductive, high strength, wear-resistant, high strength, can be used in injection molding, extrusion molding processes, light density, and diversified product structures.

1. The density of PA66/CF composite material is less than 1.3. Compared with the density of steel (7.85), it is less than one-sixth of its density, achieving the purpose of lightweight and conducive to energy saving and consumption reduction.

2. In the PA66/CF composite material system, the length of CF is about 0.5~0.7mm, the interface between the PA66 matrix and the carbon fiber is fully combined, the nylon 66 is well wrapped around the carbon fiber, the fracture surface of the PA66/CF sample is relatively rough, and the PA66/CF sample is relatively rough. CF composite materials are tough materials.

3. Compared with PA66, the mechanical properties of PA66/CF composite materials have been greatly improved. When 4 bundles of CF are added, the tensile strength of PA66/CF reaches 200.2MPa, which is approximately 130% higher than that of nylon 66, and the elongation at break is 3.3%; the bending strength reaches 280.2MPa, which is approximately 211% higher than PA66. The bending die The amount reached 13560.8MPa, which is approximately 362% higher than PA66.

Advantages of PA66 CF30 Composites

PA66 CF30 offers several advantages over traditional materials:

1. High Strength and Stiffness: The addition of carbon fiber significantly increases the strength and stiffness of the PA66 matrix. This results in a material with enhanced mechanical properties, making it suitable for applications requiring high structural integrity.

2. Lightweight: Despite its enhanced strength and stiffness, PA66 CF30% remains relatively lightweight compared to metals like steel or aluminum. This makes it an attractive choice for applications where weight reduction is critical, such as automotive and aerospace industries.

3. Improved Dimensional Stability: The incorporation of carbon fiber helps reduce dimensional changes due to temperature variations, moisture absorption, or other environmental factors. This improved stability ensures tighter tolerances and better part consistency in manufacturing processes.

4. Enhanced Chemical Resistance: PA66+CF30 exhibits better resistance to chemicals, oils, and solvents compared to unfilled PA66. This makes it suitable for applications exposed to harsh environments or chemical exposure.

5. Excellent Thermal Properties: Carbon fiber reinforcement enhances the thermal conductivity of the material, leading to improved heat dissipation. This property is advantageous in applications requiring thermal management, such as electronic components or automotive parts.

6. Reduced Wear and Abrasion: The presence of carbon fiber improves the wear resistance of 30%CF PA66, making it suitable for applications subject to friction and abrasion, such as gears, bearings, and bushings.

7. Good Electrical Insulation: PA66 30%CF maintains the electrical insulation properties of PA66 while offering improved mechanical strength. This combination makes it suitable for electrical and electronic applications where insulation and structural integrity are essential.

8. Design Flexibility: Composite materials like PA66 CF30 offer greater design freedom compared to traditional materials. Manufacturers can create complex shapes and features without sacrificing structural performance, allowing for innovative designs and cost-effective manufacturing processes.

Comparison of PA66 CF30 and PA66 GF30

| No. | Comparison Items | PA66 CF30 | PA66 GF30 |

|---|---|---|---|

| 1 | Reinforcing material | Carbon fiber – 30% | Glass fiber – 30% |

| 2 | Strength | Higher strength than PA66 GF30 in general | Relatively high strength |

| 3 | Weight | Relatively light | Heavier than PA66 CF30 |

| 4 | Corrosion resistance | Good corrosion resistance | Relatively good corrosion resistance |

| 5 | Thermal conductivity | Good thermal conductivity | Relatively poor thermal conductivity |

| 6 | Cost | Higher cost | Relatively low cost |

| 7 | Appearance | Darker color | Usually white or light color |

| 8 | Dimensional stability | Good dimensional stability | Relatively good dimensional stability |

| 9 | Specific applications | Suitable for components in aerospace fields and high-end sports equipment that require extremely high strength and low weight. | Widely used in fields such as automotive parts and electronic appliance enclosures. |

If you had any interest in this product, kindly contact us by email or send us an inquiry directly.

Read more information on chopped carbon fiber filled NYLON composites or long carbon fiber reinforced polyamide compounds, please click here.

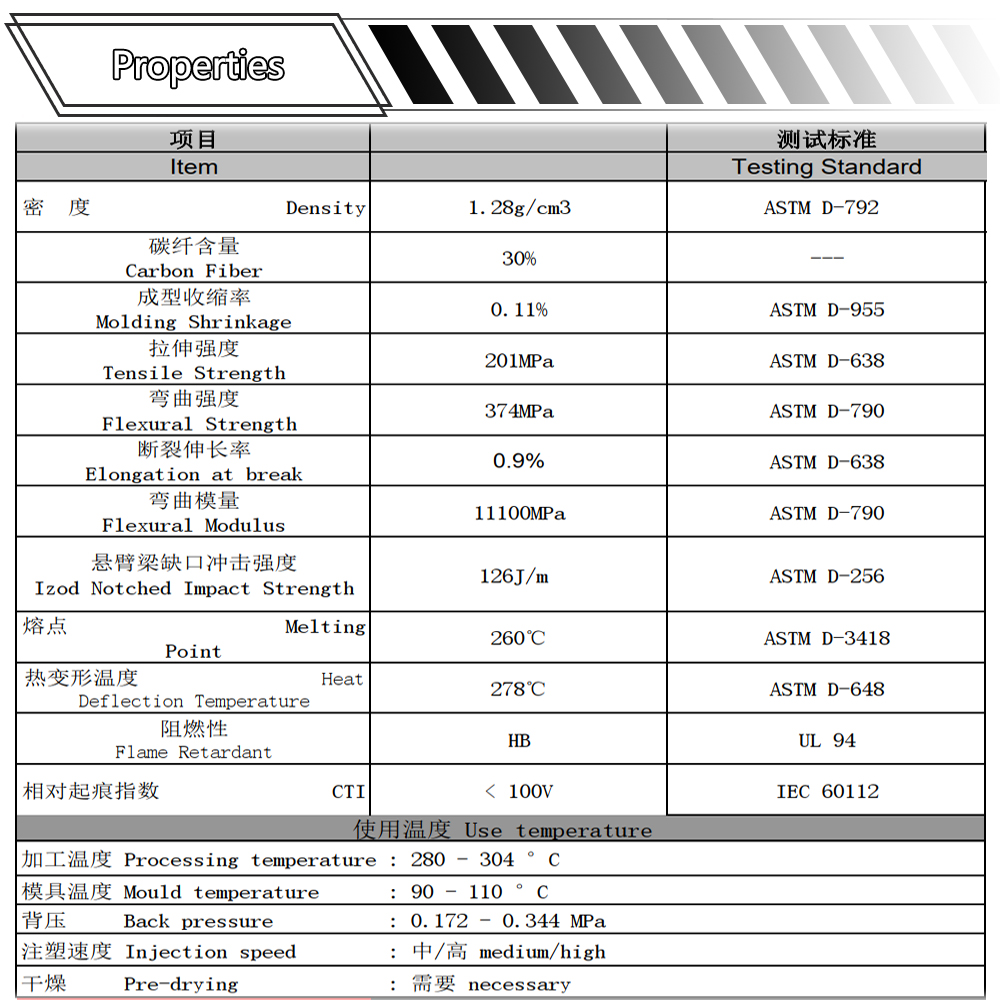

Main Technical Datasheet

Polyamide 66 (PA66) reinforced with 30% carbon fiber (CF30) offers enhanced mechanical properties compared to standard PA66.

PA66 CF30 Applications

1. Automotive Components 2. Electrical and Electronic Components 3. Industrial Equipment 4. Sporting Goods 5. Consumer Goods 6. Aerospace and Defense 7. Mechanical Engineering 8. Renewable Energy

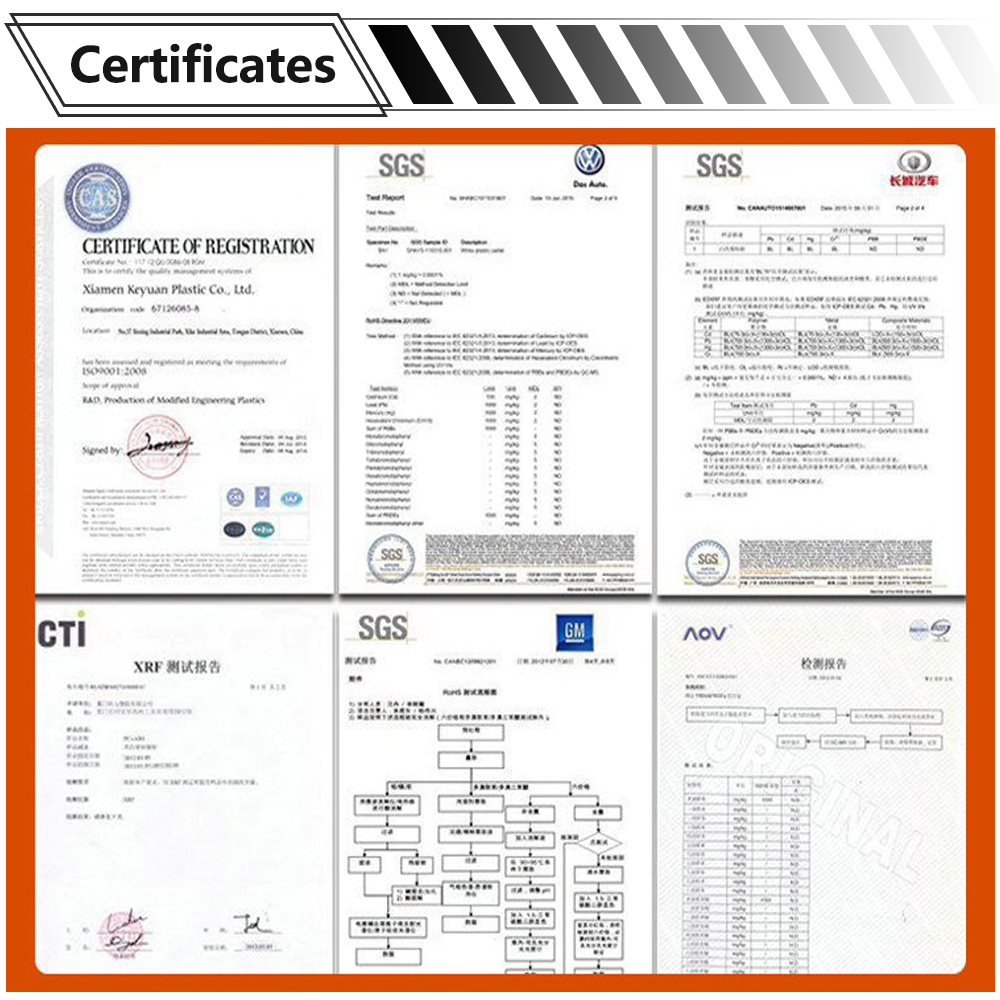

Our Certificate

**ISO Certified**: Compliant with International Organization for Standardization standards, ensuring quality management systems. **SGS Verified**: Products verified by Société Générale de Surveillance, a global leader in inspection, verification, testing, and certification services. **CTI Certified**: Certified by the Composite Technology Institute, validating product quality and performance in the field of composite materials.

Professional Manufacturer

**Specialized in CFRP**: Focused solely on Carbon Fiber Reinforced Polymer, ensuring expertise and quality in every product. **OEM/ODM Available**: Offering Original Equipment Manufacturing and Original Design Manufacturing options for tailored solutions. **Manufacturer & Exporter**: Handling the entire production process in-house and delivering globally. **Customized Reinforcement**: Providing tailored reinforcement solutions to meet specific project requirements. **Injection/Extrusion Grade**: Offering CFRP materials suitable for both injection molding and extrusion processes. **Competitive Prices**: Ensuring the best pricing without compromising on quality. **In-time Delivery**: Commitment to timely delivery schedules, ensuring projects stay on track. **Excellent Service**: Dedicated to providing outstanding customer service and support throughout the process.

How to cooperate with us?

Carbon (Xiamen) New Material Co., Ltd. is located in Xiamen, a beautiful coastal city of China. Add.: No.27 Hongxi Road, Xiang'an Dist., Xiamen, Fujian Province, China. Welcome to contact us at any time.

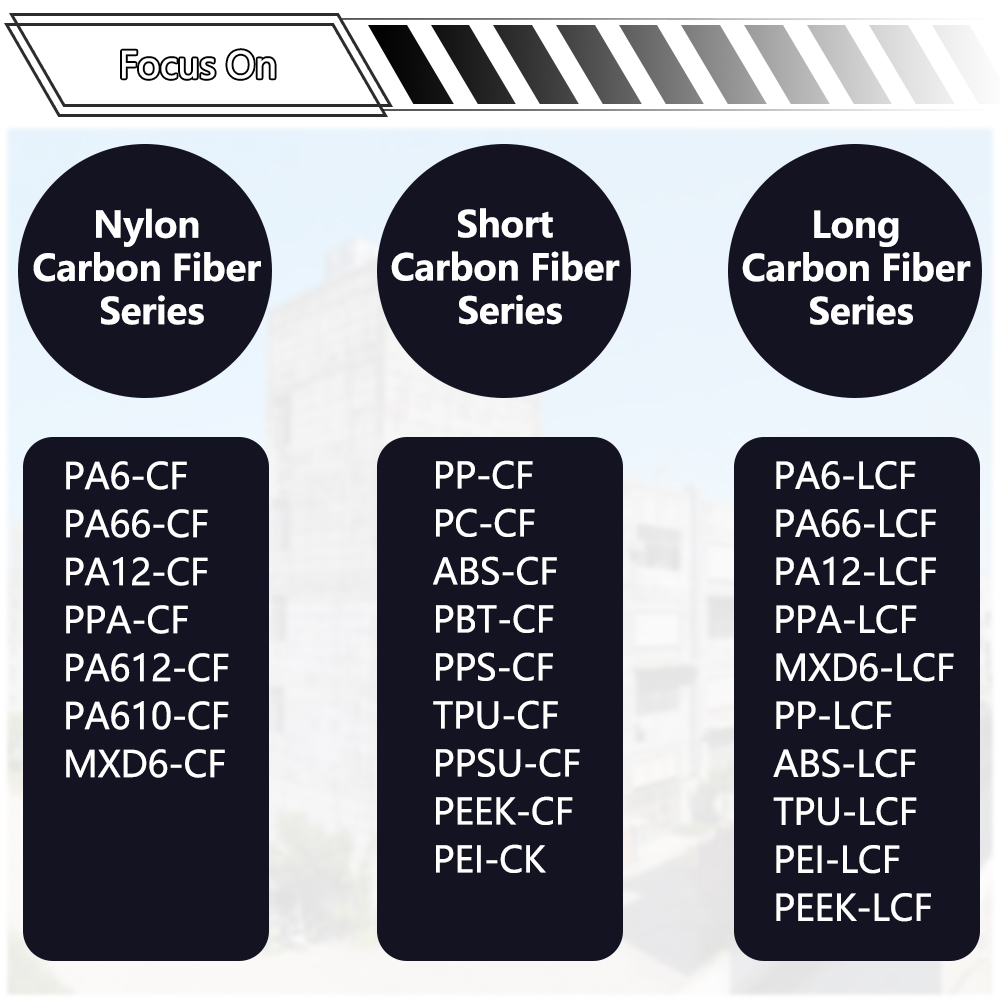

Focus On

We're committed to offering a series of customized services of carbon fiber composite materials, focusing on carbon fiber modified materials such as reinforcement, conductivity, anti-static, etc. to meet your various application demands.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.