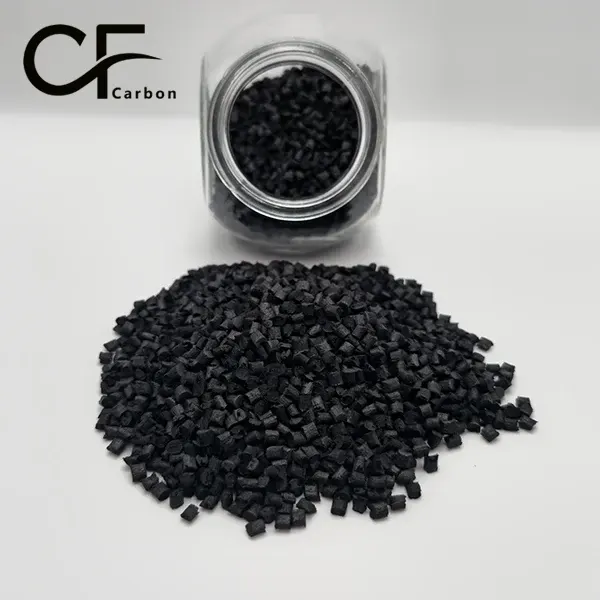

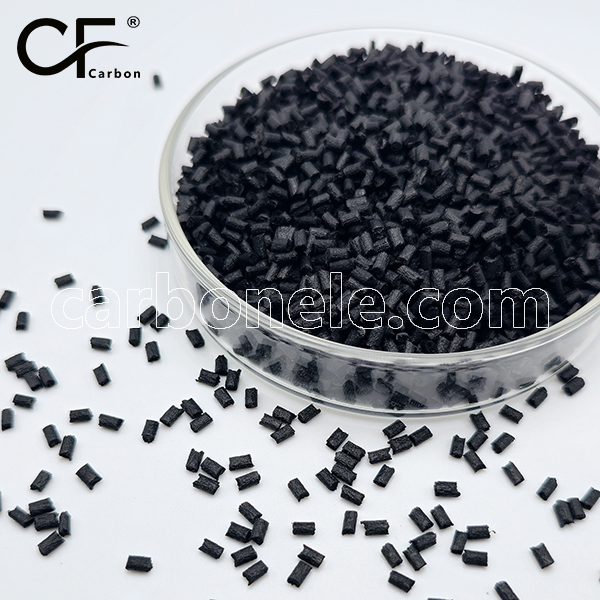

PA66 CF20 Black PA66-CF-BCA2 Manufacturer

PA66 CF20 combines the properties of PA66 with the benefits of carbon fiber reinforcement, resulting in a high-performance material suitable for a wide range of demanding applications across various industries like automobile parts.

- Model: PA66-CF-BCA2

- Manufacturer: Yes

- MOQ: 1000kgs

- Free Sample: 1-10kgs

- OEM/ODM: Acceptable

- Filler: Carbon fibers, additives, etc.

- Molding Process: Injection/extrusion molding

What’s PA66 CF20 ?

PA66 CF20 refers to a type of composite material made from Polyamide 66 (PA66) reinforced with 20% carbon fiber (CF). PA66 is a synthetic thermoplastic polymer known for its strength, stiffness, and resistance to heat, wear, and chemicals. When carbon fiber is added to PA66 in a 20% concentration, it enhances these properties even further:

1. Strength and Stiffness: Carbon fiber reinforcement significantly increases the tensile strength and stiffness of PA66 CF20% compared to unfilled PA66. This makes it suitable for applications requiring structural integrity and durability.

2. Lightweight: Despite being strong and stiff, carbon fiber is lightweight. Incorporating it into PA66 reduces the overall weight of the composite compared to metals, while maintaining or even improving strength.

3. Heat Resistance: PA66 20%CF retains the good heat resistance typical of PA66, making it suitable for applications where exposure to high temperatures is a concern.

4. Dimensional Stability: Carbon fiber reinforcement also improves dimensional stability, reducing warping or deformation under load or temperature changes.

5. Electrical Conductivity: Carbon fiber can add some degree of electrical conductivity to PA66 20% CF, depending on the specific formulation and fiber type used.

Applications of PA66 CF20 include automotive components, aerospace parts, industrial equipment, and sporting goods where a balance of strength, stiffness, and light weight is critical. However, it’s important to note that the exact properties and performance can vary depending on the manufacturing process and the specific carbon fiber used.

A real application case of PA66 CF20 manufactured by Carbon (Xiamen) New Material

Recently, a type of PA66 + CF20 (20% carbon fiber reinforced polyamide 66) developed by Carbon (Xiamen) New Material Co., Ltd. has been applied in a high-performance racing project named “Future Power”. This racing project is committed to creating an ultra-lightweight and high-strength racing car to challenge the ultimate speed and provide more energy-efficient solutions in the context of increasingly strict environmental protection regulations.

In the “Future Power” project, the application of PA66 20% Carbon Fiber is reflected in multiple key components of the racing car. The car body shell adopts PA66+CF20 provided by Carbon (Xiamen) New Material Co., Ltd. This material not only has excellent mechanical strength and rigidity, but also is much lighter in weight than traditional metal materials. The design of the racing car body has undergone precise calculation and optimization, significantly reducing the weight of the body and thereby improving the acceleration performance and handling stability of the racing car.

In addition, the suspension system and brake calipers of the racing car also use PA66 CF20 provided by Carbon (Xiamen) New Material Co., Ltd. These components perform outstandingly when subjected to high-frequency impacts and high-temperature environments, ensuring the reliability of the racing car under extreme conditions. Due to the superior thermal stability of the PA66 – CF20 material, when the racing car is running at high speed, the deformation and wear of the components are minimal, greatly improving the overall durability.

This case not only demonstrates the revolutionary application of PA66 + 20% CF material produced by Carbon (Xiamen) New Material Co., Ltd. in the field of racing, but also highlights the potential of future high-performance materials in promoting technological innovation and enhancing environmental sustainability.

What significant advantages does PA66 CF20 has compared to other materials?

Nylon 66 CF20 has extremely excellent mechanical strength and rigidity, far surpassing many common materials. In terms of weight, it is much lighter than traditional metal materials, greatly reducing the overall load and thereby effectively improving the portability and flexibility of the product. Its thermal stability is extremely superior and it can easily withstand high-temperature environments and high-frequency impacts. In addition, Polyamide 66 CF20 is relatively low in cost and has a high cost performance. Because of this, it has a broad application prospect in many fields. For example, in the automotive manufacturing industry, it can not only significantly improve the performance of the car, but also control the cost well.

Learn more about 0ther PA66 crabon fiber compounds or carbon fiber reinforced nylon composites by clicking here or watching relevant videos on YouTube.

About Us

Combining R&D, production and sales, depending on a professional R&D team, the modern and advanced factory as well as meticulous pre-sales and after-sales services, Carbon (Xiamen) New Material is dedicated to supplying high-quality carbon fiber reinforced thermoplastics, establishing one-stop services and providing comprehensive solutions of CFRTP products.

Our Laboratory

1. Performance Evaluation Equipment Featuring versatile material testing machines, dynamic mechanical analyzers (DMA), thermogravimetric analyzers (TGA), differential scanning calorimeters (DSC), thermal conductivity meters, and electrical property analyzers, this equipment is designed to thoroughly assess the diverse properties of materials. 2. Microstructural Analysis Instruments Including scanning electron microscopes (SEM), transmission electron microscopes (TEM), and X-ray diffraction (XRD) analyzers, these instruments are used for examining and analyzing the microstructure and phase composition of materials.

Our R&D Team

Our R&D team already possesses interdisciplinary professional knowledge, covering fields such as materials science and chemical engineering. They have acute market insight and can accurately grasp the industry demands and trends. They are equipped with innovation capabilities and continuously optimize the performance of carbon fiber reinforced materials. They are also proficient in advanced R&D technologies and tools, and have a teamwork spirit to complete R&D tasks efficiently.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.