PA6 CF30 Nylon 6 30% Carbon Fiber Reinforced Compounds

PA6 CF30 is a 30% carbon fiber reinforced polyamide 6 with high flexural strength and good sliding performances. PA6 CF30 is a material that tends to absorb moisture from the air. If PA6 CF30 is not fully dried before injection molding, problems can occur during the injection molding or molding process. For best print quality, the filament should be pre-dried at 70°C for 12-24 hours before printing, or a special drying chamber can be used to dry the filament under controlled conditions.

- Product: PA6 CF30 Compounds

- Formula: Carbon fibers, additives, etc.

- Color: Black

- Manufacturer: Yes

- OEM/ODM: Acceptable

- Molding Process: Injection Molding

- Features: Conductivity, wear resistance, lightweight, etc.

-

What’s PA6 CF30?

Fiber-reinforced plastics such as PA6 CF30% polymers are composite materials composed of high-strength fibers and elastic plastics. They have high stiffness and strength, making the products superior in heat resistance, impact resistance, and dimensional stability, which meet their needs in industrial products and daily life. usage requirements. In recent years, automobiles have been developing toward miniaturization and light-weighting. The volume of the engine room has shrunk and the temperature has increased, requiring components under the hood to be more resistant to high temperatures.

PA6 CF 30 can fully meet the above requirements, so it is widely used in the manufacturing process of automobile parts. For example, car engine parts, electrical parts, body parts, airbags and many other parts can not only provide good protection, but also make the car more beautiful.

-

Why to Choose PA6 CF30 Compared to Nylon 6 (PA6)?

PA6 CF30 has higher strength and rigidity, which can meet the application scenarios with higher requirements for mechanical properties. It performs outstandingly in terms of tensile resistance and compression resistance. At the same time, PA6 30%CF has better thermal stability and can still maintain good performance in high-temperature environments, with a wider application range.

In addition, the wear resistance of PA6 30% CF is also better, which can effectively extend the service life of the product. In some occasions where weight reduction is required, due to the addition of carbon fibers, PA6 + CF30 is lighter while ensuring strength. For example, in the fields of automotive parts and aerospace, PA6 CF30 is often a better choice.

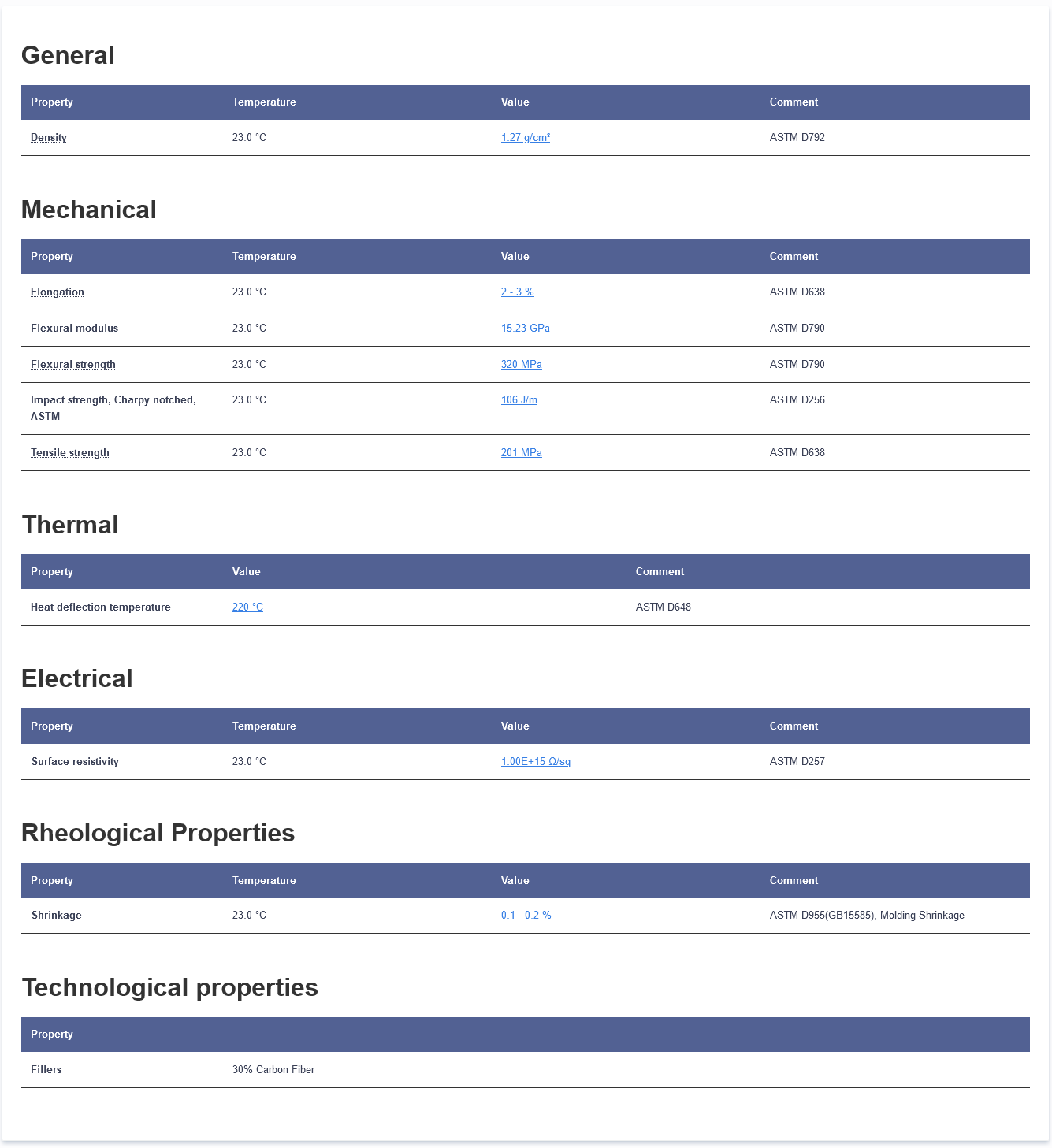

Figure 1 – The Technical Datasheet of Nylon Polyamide 6 CF30 Composites

-

A Real Case Shared with You

In the fiercely competitive, innovative and excellent modern automotive industry, PA6 CF30 developed and produced by Carbon (Xiamen) New Material has occupied a pivotal position by virtue of its outstanding performance. Take the car engine hood, a key component, as an example. Traditional materials tend to encounter thorny problems such as deformation, aging and performance degradation under the harsh working environment of high temperature and high intensity.

PA6 30% carbon fiber exhibits remarkable high-temperature resistance and high strength. When the car engine is in continuous operation, it will continuously generate a large amount of heat. At this time, PA6 CF30 provided by Carbon (Xiamen) New Material can remain as stable as a mountain in this high-temperature environment, maintaining good structural stability and hardly showing any deformation. Meanwhile, its high-strength feature enables the engine hood to calmly cope with various external impacts and frequent vibrations, providing a solid and reliable safety protection for the engine.

In the actual application scenario, a world-renowned and prestigious automotive brand resolutely adopted PA6 – CF30 from Carbon (Xiamen) New Material to manufacture the engine hood. After a long period of use and going through the severe tests of various complex road conditions, this engine hood has always performed excellently. It not only shows no common problems such as deformation and cracking at all, but also weighs about 20% less compared to the engine hood made of traditional materials.

This significant weight reduction achievement effectively improves the fuel economy of the car, saving a lot of fuel expenses for car owners. Moreover, due to the good corrosion resistance of Nylon 6 CF30, the service life of the engine hood is significantly prolonged. This means that the cost of vehicle maintenance is significantly reduced, and car owners do not need to replace the engine hood frequently, bringing a more economical and convenient usage experience to users.

Read more about Nylon PA6 CF composites, please click here. or watch relevant CFRTPs videos on YouTube.

What's Carbon Fiber?

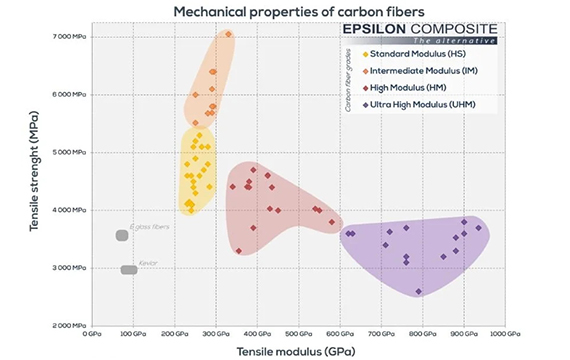

Carbon fiber exhibits several mechanical properties that make it highly desirable for various engineering applications. Here are some key properties:

1. High Strength

2. Stiffness

3. Low Density

4. Fatigue Resistance

5. Corrosion Resistance

6. Temperature Resistance

7. Electrical Conductivity

8. Dimensional Stability

PA6 CF30 & PA6 GF30

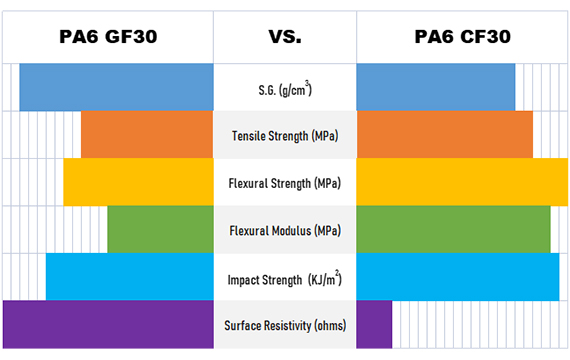

PA6 is a semi transparent or opaque milky white particle with characteristics such as thermoplastic, lightweight, good toughness, chemical resistance, and durability. Its melting point is 223 ℃.

GF: refers to glass fiber, with a density of 2.7g/cm3.

CF: refers to carbon fiber, with a density of 1.8 g/cm3.

Compared with fiberglass reinforced PA6, carbon fiber reinforced PA6 has the characteristics of low density, high strength, and conductivity.

Stringent Quality Control System

Carbon (Xiamen) New Material has put into effect a thorough quality inspection process throughout the entire course, ranging from the selection of raw materials to the dispatch of finished products. In the acquisition of raw materials, high-precision tests are conducted. During the production process, each stage is closely monitored and sampled. Non-destructive testing is utilized to detect flaws in the finished goods. This meticulous method, along with continuous improvement endeavors based on the analysis of quality data, guarantees that every product leaving the factory conforms to or exceeds the most exacting industry standards. A prime example is their zero-defect record for a specific high-demand product line.

Our Lab.

Carbon (Xiamen) New Material Co., Ltd. is a factory integrating research, production and sales, specializing in thermoplastic engineering plastics reinforced with carbon fibers. The laboratory of this company should have advanced testing equipment to accurately analyze the properties of carbon fiber reinforced thermoplastic engineering plastics. There should be devices to simulate various usage environments to test the stability of the materials. It also needs to be equipped with a professional team that can carry out innovative research and development to ensure the leading position and high quality of the company's products.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.