PA6-CF20 Composite – 20% Carbon Fiber Strength

PA6-CF20 is a high-performance polyamide composite with 20% carbon fiber reinforcement, ideal for automotive, industrial, and consumer goods applications. It offers tensile strength, impact resistance, thermal stability, low water absorption, customizable fiber length and concentration, and is recyclable, making it a sustainable choice.

- Model number: PA6-CF-BCA2

- Matrix Resin: Nylon6 (Polyamide6) (PA6)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PA6-CF20: Overview and Key Advantages

PA6 CF20 is a cutting edge polyamide composite that incorporates 20% carbon fibers, offering an exceptional blend of strength, flexibility, and lightweight characteristics. This innovative material is specifically designed for applications where high durability and performance are crucial, yet without the excessive weight typically associated with traditional composites. Below is an in-depth overview of its key properties and advantages:

| Property | Value/Description |

|---|---|

| Base Material | Polyamide 6 (PA6) |

| Reinforcement | Carbon Fibers (CF) |

| Density | Approximately 1.4 g/cm³ |

| Tensile Strength | 120-160 MPa (varies with fiber content) |

| Flexural Modulus | 5000-6000 MPa |

| Impact Resistance | Very High (up to 150% improvement over unreinforced PA6) |

| Thermal Stability | Stable up to 220°C |

| Melt Flow Index (MFI) | Low (typically < 12 g/10 min) |

| Water Absorption | Very Low (up to 0.5% moisture uptake) |

| Color | Typically black (custom colors available) |

| Processing Method | Injection molding, extrusion |

PA6-CF20 Key Properties

Flexibility and Strength: The integration of 20% carbon fibers greatly enhances the flexibility and strength of PA6 CF20. This makes it particularly well-suited for demanding automotive and industrial applications. The high carbon fiber content allows the material to endure substantial stress without compromising its structural integrity. As a result, components made from PA6 CF20 can operate reliably under heavy loads and dynamic conditions.

Impact Resistance: One of the standout features of PA6 CF20 is its exceptional impact resistance, which shows an impressive improvement of up to 150% over unreinforced PA6. This enhanced durability is critical for applications involving outdoor equipment and products that undergo rigorous use, such as automotive parts and industrial tools. By ensuring reliable performance over time, PA6 CF20 minimizes the risk of failure, making it a trusted choice for manufacturers.

Thermal Stability: PA6 CF20 exhibits remarkable thermal stability, withstanding temperatures up to 220°C. This property is essential for industrial applications, where materials must endure high temperatures without losing functionality. The ability to maintain mechanical properties in elevated temperature conditions makes PA6 CF20 ideal for components that are exposed to heat, such as those used in automotive engines or electronic housings.

Water Absorption: Another critical advantage of PA6 CF20 is its very low water absorption, typically less than 0.5%. This characteristic is vital for extending the lifespan of products, especially in outdoor and humid environments. Low moisture uptake reduces the risk of dimensional changes and material degradation, ensuring that components retain their integrity and performance over time.

Customization and Sustainability

PA6 CF20 offers significant customization options, allowing manufacturers to modify fiber length and concentration to meet specific performance requirements. The 20% carbon fiber content can be tailored to enhance particular properties, making this material adaptable to various applications. This flexibility in design not only improves product functionality but also expands the possibilities for innovative engineering solutions.

In addition to its performance benefits, PA6 CF20 is a recyclable material, aligning with the growing demand for environmentally friendly products. As sustainability becomes increasingly important in manufacturing, the ability to recycle PA6-CF20 contributes to reduced waste and a lower environmental impact. This makes it an appealing choice for companies looking to meet eco-conscious consumer preferences.

Applications

PA6 CF20 is versatile and is utilized across various sectors, including:

- Automotive: This composite is ideal for a range of automotive components, including structural parts, interior trims, and under the hood applications. Its lightweight nature contributes to improved fuel efficiency, while its high strength and durability enhance vehicle safety and performance.

- Consumer Goods: PA6 CF20 is suitable for robust consumer products such as sports equipment, luggage, and protective gear. Its impact resistance and low water absorption make it a preferred material in these markets, where performance and durability are essential.

- Electrical and Electronics: In the electrical and electronics sector, PA6 CF20 is used for housings and components that require strength and thermal stability. This is particularly important for applications involving heat-generating electronics, where reliable operation is critical for safety and performance.

- Industrial: The composite is widely employed in machinery and tools, offering reliability and longevity in demanding industrial environments. Its mechanical properties help reduce maintenance costs and downtime, making it a cost-effective solution for manufacturers.

Personal Thoughts

PA6 CF20 stands out as an innovative material that combines lightweight design with exceptional mechanical performance. Its customizable features allow manufacturers to create products tailored to specific applications, particularly in automotive and industrial sectors. Moreover, its recyclability addresses the growing demand for sustainable materials, making it a responsible choice for manufacturers. Overall, PA6 CF20 enhances performance while promoting sustainability, establishing itself as an excellent option for future applications.

Conclusion

In summary, PA6 CF20 is a highly versatile, high performing material that integrates the advantages of polyamide with the strength of carbon fibers. Its unique properties make it suitable for a wide range of applications across multiple industries. As the demand for advanced materials continues to rise, PA6 CF20 emerges as a reliable solution for manufacturers seeking to enhance performance while ensuring cost efficiency and sustainability.

If you want to get more information about PA6-CF20, you can vist Youtube.

Click here to contact us.

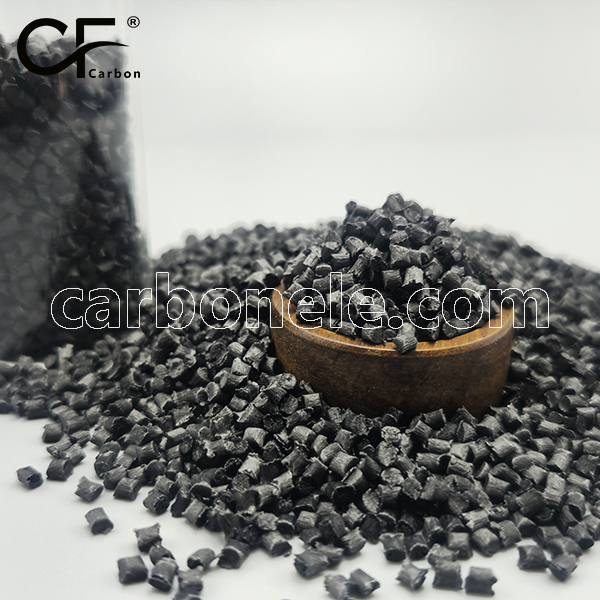

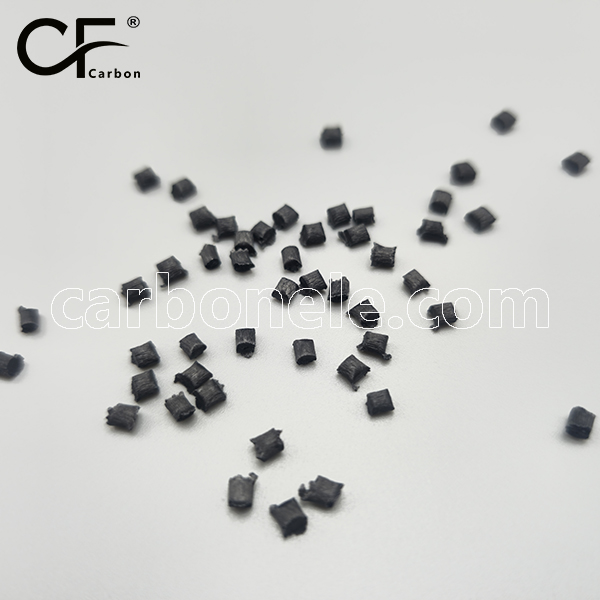

PA-CF20 granules

PA-CF20 granules typically have a round or irregular shape, with diameters generally ranging from 2 to 5 millimeters. This shape allows for uniform flow during processing, ensuring consistency in molding and extrusion techniques. The granules have a smooth surface, facilitating easy mixing with other materials and enhancing their applicability across various uses. Their small size also makes PA-CF20 granules convenient for storage and transportation, effectively minimizing space requirements.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.