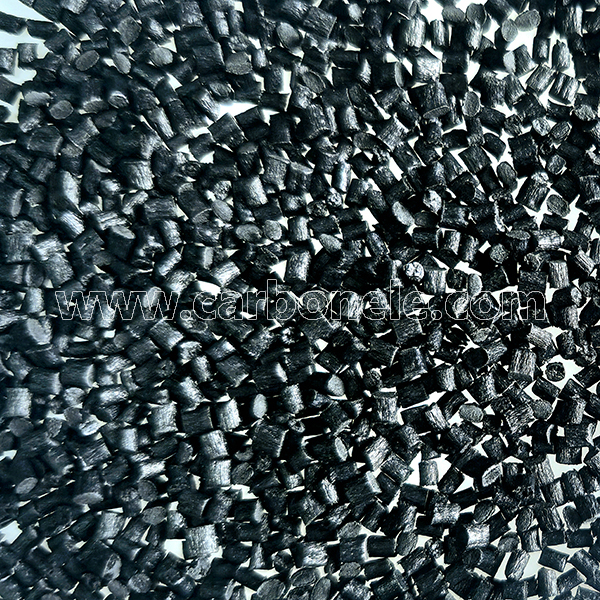

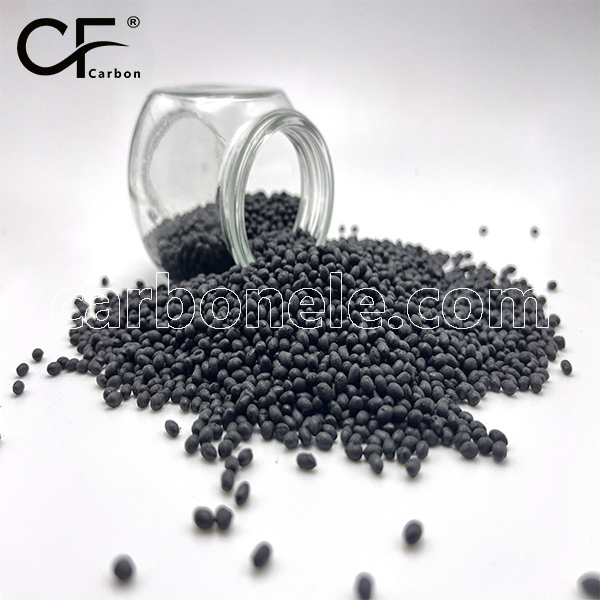

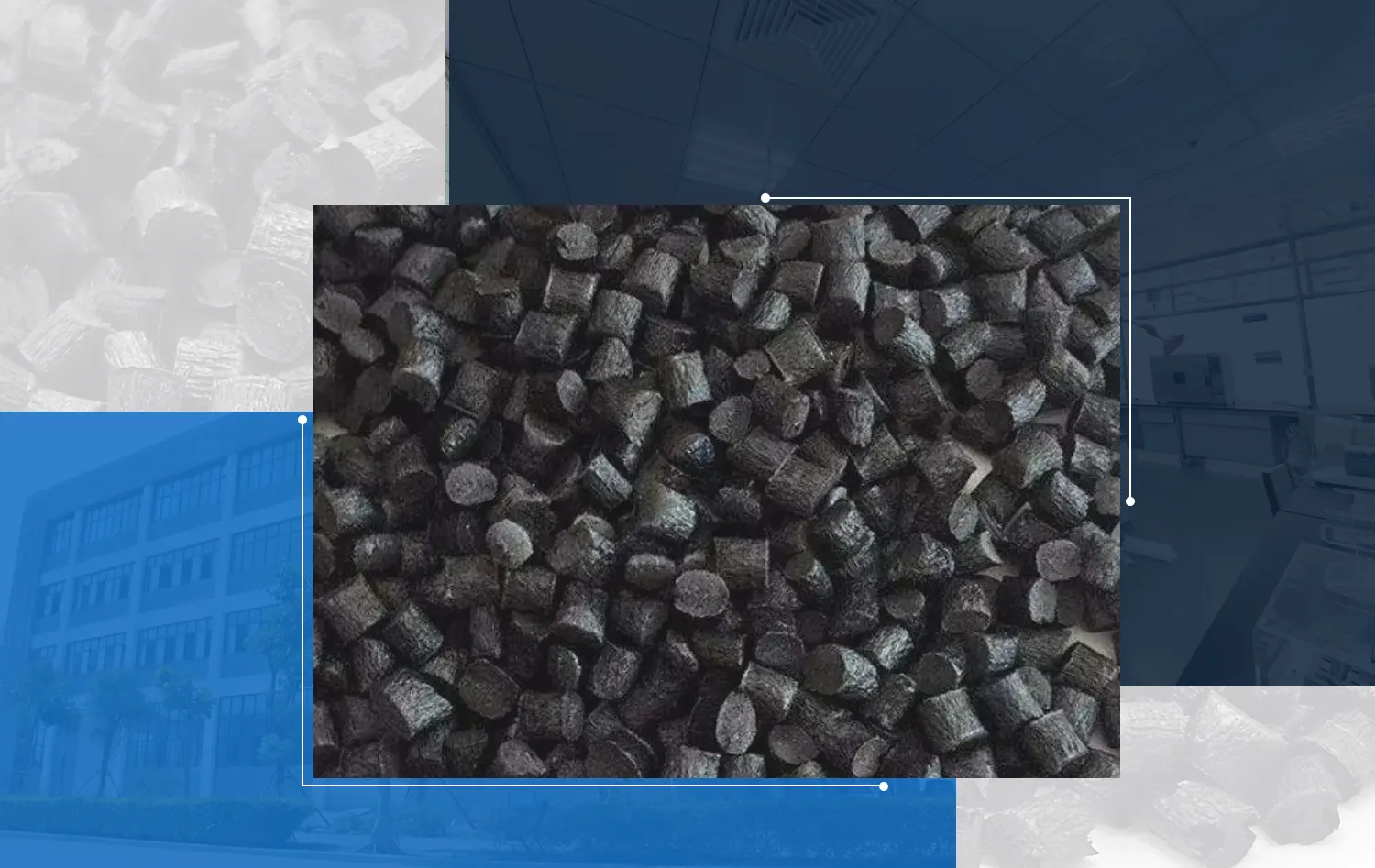

PA12 Carbon Fiber Composite Materials

PA12 Carbon Fiber Composite Materials are a new high-performance compound that mixes carbon fiber with polyamide 12 to form a uniform particle mass. PA12 Carbon Fiber material is heat-resistant, corrosion-resistant, lightweight, strong and stiff. It is widely used in multiple industries (including but not limited to) aerospace, automotive industry, rail vehicles and medical equipment.

- Brand: Carbonele

- Material: PA12 Carbon Fiber Compounds

- Color: Black

- Advantage: Corrosion Resistance, Conductivity

- OEM/ODM: Acceptable

What’re the composites?

PA12 Carbon Fiber Composite Materials represent a kind of advanced polymer composite that integrates polyamide 12 (PA12) with carbon fibers. PA12 is renowned for its remarkable toughness, extremely low moisture absorption rate, and outstanding chemical resistance. Meanwhile, the addition of carbon fibers significantly enhances its mechanical properties. Typically, this composite incorporates a considerable proportion of carbon fiber – often approximately ranging from 20% to 30% – which leads to substantial improvements in strength, stiffness, and dimensional stability.

Key features of PA12 Carbon Fiber Composites

1. Exceptionally High Strength-to-Weight Ratio: The carbon fibers play a crucial role in significantly escalating the material’s tensile strength and stiffness, all the while maintaining its lightweight nature. This characteristic makes it an ideal choice in scenarios where minimizing weight while maximizing strength is of paramount importance.

2. Minimal Thermal Expansion: The inclusion of carbon fibers effectively reduces the thermal expansion of PA12. This results in enhanced dimensional stability and a significant reduction in warping during fluctuations in temperature. Such properties are especially valuable in applications where precise dimensions and stability are critical.

3. Superb Chemical Resistance: The inherent chemical resistance of PA12 is successfully preserved within the composite, thereby rendering it highly suitable for use in harsh and demanding environments. This ensures the material’s longevity and reliability even when exposed to aggressive chemicals.

4. Impressive Impact Resistance: The combination of PA12 and carbon fibers offers superior impact resistance when compared to materials that are not reinforced. This makes the composite a reliable option in applications where the ability to withstand sudden and forceful impacts is essential.

These composites are frequently utilized in high-performance applications within the aerospace, automotive, and industrial sectors, where factors such as strength, durability, and precision hold crucial significance. Their unique properties make them indispensable in the creation of components that must meet the most exacting standards and operate reliably under challenging conditions.

Please click here to watch videos on carbon fiber reinforced thermoplastics.

PA12 carbon fiber composite materials in drones

PA12 carbon fiber composite materials have gained widespread attention in the aerospace industry for their exceptional performance. Recently, a leading aerospace equipment manufacturer incorporated this advanced material into the design of their latest drone, successfully addressing the strength and weight challenges that traditional materials could not.

The company faced the challenge of developing a drone wing that was both lightweight and capable of withstanding extreme operating conditions. PA12 carbon fiber composites emerged as the ideal solution. The key advantage of this material lies in its outstanding strength-to-weight ratio, allowing the wing to achieve high structural strength while significantly reducing overall weight. This improvement enhanced the drone’s flight efficiency and extended its range.

Moreover, PA12 carbon fiber composites exhibit extremely low thermal expansion. In practical use, this characteristic ensures that the wing maintains high stability and precision even when subjected to severe temperature fluctuations. This is crucial for the reliability of high-performance drones in various flying conditions.

The PA12 carbon fiber composites supplied by Carbon (Xiamen) New Material supported the manufacturer’s innovative design with their superior quality, leading to a significant breakthrough in the drone industry. This successful case not only highlights the immense potential of PA12 carbon fiber composites but also paves the way for new possibilities in the design and application of future aerospace vehicles.

If you are interested in our products, please do not hesitate to send an inquiry now.

PA12 CF Composites

Heat-resistant, corrosion-resistant, lightweight, strong and stiff. Widely used in multiple industries aerospace, automotive industry, medical equipment.

High Quality Carbon Fibers

Carbon fiber has attracted the attention of researchers due to its excellent properties such as light weight, high high-temperature load-bearing strength, low density, high modulus and good chemical resistance.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.