What Is Different Between PP And PP-CF? - Carbon Fiber Compounds Manufacturer | Supplier

Oct-25-2024

Differences Between PP and PP-CF.

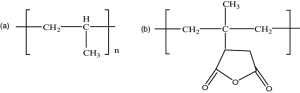

Chemical structure of (a) polypropylene and (b) CF-PP

-

Composition:

- PP (Polypropylene): A thermoplastic polymer made from propylene monomers, recognized for its versatility, lightweight nature, and ease of processing.

- PP CF (Polypropylene Carbon Fiber Composite): A composite material that enhances polypropylene with carbon fibers, significantly improving its mechanical properties.

-

Mechanical Properties:

- PP: Offers moderate tensile and flexural strength suitable for various general-purpose applications.

- PP CF: Incorporation of carbon fibers greatly enhances tensile and flexural strength, making it stronger and stiffer than standard polypropylene.

-

Weight:

- PP: While lightweight, it may not perform as well under high-load conditions.

- PP CF: Retains a low weight while providing improved strength, making it ideal for weight-sensitive applications, particularly in automotive and aerospace sectors.

-

Stiffness:

- PP: Generally less rigid, making it more susceptible to deformation.

- PP CF: The carbon fibers increase rigidity, allowing the material to maintain its shape and resist deformation under stress.

-

Impact Resistance:

- PP: Provides basic impact resistance but may not withstand severe conditions.

- PP CF: Demonstrates superior impact resistance, making it suitable for demanding applications requiring durability.

-

Chemical Resistance:

- PP: Known for excellent resistance to a wide range of chemicals, making it versatile for various applications.

- PP CF: Retains the chemical resistance of polypropylene while offering enhanced strength, ideal for industrial settings where exposure to corrosive substances is common.

-

Moisture Absorption:

- PP: Exhibits moderate moisture absorption, potentially affecting its dimensional stability in humid conditions.

- PP CF: Typically has lower moisture absorption rates, maintaining dimensional stability and mechanical properties.

Applications of PP-CF

1. Automotive Components:

- PP CF5: Used for lightweight interior parts, such as dashboards and trims, balancing strength with cost-effectiveness.

- PP CF10: Ideal for structural components requiring higher strength and impact resistance, enhancing vehicle safety.

- PP CF20: Suitable for exterior parts, offering resistance to environmental factors while maintaining performance.

2. Industrial Products:

- PP CF20: Applied in machinery parts and housings that need enhanced durability and stiffness for long-term use.

- PP CF30: Used in tools requiring high performance under stress, along with better chemical resistance.

- PP CF40: Ideal for industrial applications where superior mechanical properties are critical, such as manufacturing equipment.

3. Consumer Goods:

- PP CF5: Commonly used in luggage and sporting equipment, providing a lightweight yet durable solution.

- PP CF20: Perfect for high-end household items, ensuring both strength and aesthetic appeal.

- PP CF30: Applied in premium consumer products demanding high performance, such as advanced electronics casings.

4. Aerospace:

- PP CF30: Suitable for lightweight components needing high strength and rigidity, contributing to overall weight reduction in aircraft.

- PP CF40: Designed for critical structural parts in aerospace, offering maximum durability and reliability under extreme conditions.

- PP-CF60: Utilized in advanced aerospace applications where the highest levels of strength and performance are required.

Summary

In summary, the differences between PP and PP-CF are significant, particularly in terms of mechanical properties, weight, and applications. PP-CF offers enhanced strength, rigidity, and impact resistance, making it ideal for demanding environments. Different grades of PP-CF—such as PP-CF5, PP-CF10, and PP-CF20—cater to various industrial needs, including automotive, industrial products, consumer goods, and aerospace applications. With the integration of carbon fibers, PP-CF is positioned as a versatile solution for performance-driven applications across multiple sectors.

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...