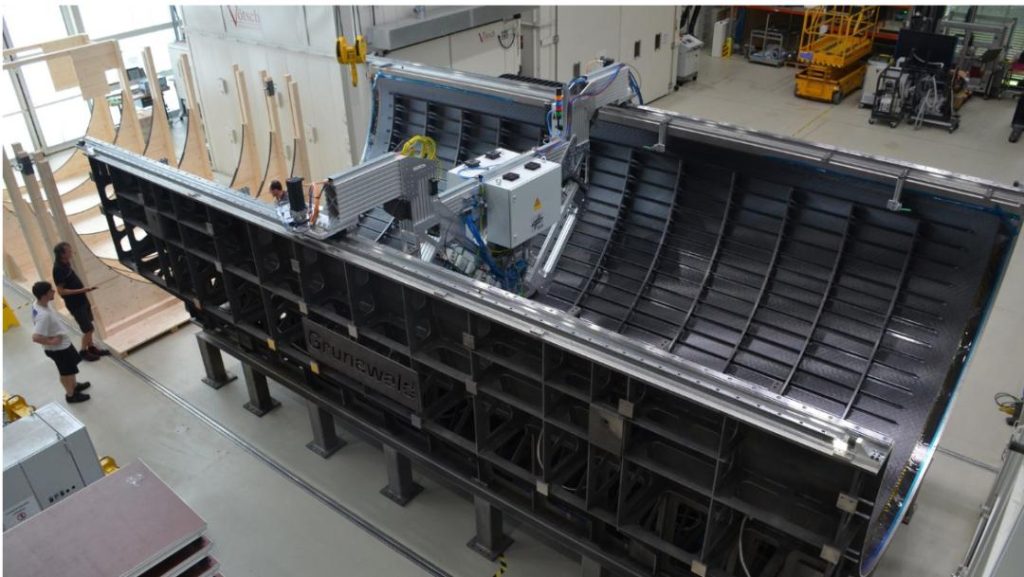

The World's Largest Carbon Fiber Reinforced Thermoplastic Composite Fuselage Successfully Manufactured

The world’s largest carbon fiber reinforced thermoplastic composite fuselage has been successfully manufactured.

Upper and lower body shells: As part of the “Intelligent Multi functional Integrated Thermoplastic Composite Body” (STUNNING) project, the lower body shell of the thermoplastic composite material is cured and formed by hot pressing tanks under high temperature and high pressure conditions. The upper body shell of thermoplastic composite materials is manufactured using fiber strip laying and in-situ consolidation technology, which is jointly completed by multiple teams.

The upper and lower body shells both have a high degree of pre integration and are designed with an almost rivet free architecture, reducing weight by 10% compared to existing traditional bodies. Automated pre integration further improves manufacturing efficiency and enhances local manufacturing flexibility, eliminating the need for all components to be placed inside enclosed bodies and manually installed in narrow space conditions.

In addition, the reduction in aircraft structural weight significantly improves fuel efficiency during flight.

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...