Strength Different Between PPA And PPA-CF - Carbon Fiber Compounds Manufacturer | Supplier

Dec-24-2024

Differents between TPU and TPU-CF (Thermoplastic Polyurethane – Carbon Fiber Reinforced Plastic)

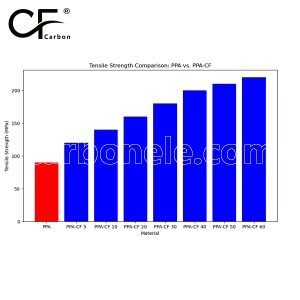

The strength difference between PPA (Polyphthalamide) and PPA-CF (Carbon Fiber Reinforced Polyphthalamide) is significant, primarily due to the incorporation of carbon fibers into the PPA matrix. Here’s a breakdown of the key differences:

Tensile Strength

- PPA: Polyphthalamide is known for its excellent mechanical properties, including high tensile strength, stiffness, and resistance to creep. It typically offers good performance in structural applications but is not as strong as carbon fiber-reinforced versions.

- PPA-CF: Adding carbon fibers to PPA increases its tensile strength dramatically. The carbon fibers reinforce the polymer matrix, making PPA CF much stronger, especially in terms of load bearing and resistance to deformation under stress. Tensile strength can be enhanced by 30-50%, depending on the fiber content (e.g., 10% vs. 30% carbon fiber).

Flexural Strength

- PPA: PPA has high flexural strength, making it suitable for applications where bending or flexing is required. It is resistant to deformation and provides good dimensional stability.

- PPA-CF: The carbon fibers in PPA CF significantly enhance its flexural strength. Carbon fiber reinforcement adds stiffness and rigidity, making PPA CF less prone to bending and more capable of withstanding higher loads without deflection.

Impact Resistance

- PPA: PPA generally has good impact resistance, though it can be brittle at lower temperatures.

- PPA-CF: The impact resistance of PPA CF is usually lower than that of pure PPA. While carbon fibers strengthen the material in terms of stiffness, they can make it more brittle, reducing its ability to absorb impact energy. The balance between fiber content and resin matrix plays a key role here.

Stiffness (Modulus of Elasticity)

- PPA: Polyphthalamide is already a stiff material with good dimensional stability, especially in high-temperature environments.

- PPA-CF: The modulus of elasticity increases significantly with carbon fiber reinforcement, making PPA CF much stiffer. This makes it ideal for applications where rigidity and resistance to deformation under load are critical.

Wear and Abrasion Resistance

- PPA: PPA offers excellent wear resistance, especially at higher temperatures.

- PPA-CF: Carbon fibers improve the wear resistance of PPA, especially in applications involving friction or sliding components. The carbon fiber reinforcement enhances the durability of the material under abrasive conditions.

Summary

- PPA provides strong mechanical properties on its own, but PPA CF is significantly stronger, stiffer, and more resistant to deformation under load due to the reinforcing effect of the carbon fibers.

- PPA-CF is ideal for high-strength, high-stiffness applications where weight reduction and dimensional stability are important, but the material can become more brittle, reducing its impact resistance.

If you want to get more information about PPA-CF, you can vist our Youtube.

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...