PP-CF Is The Perfect Combination Of Light Weight And High Strength - Carbon Fiber Compounds Manufacturer | Supplier

Materials science is pushing invention in all spheres of life in the age of efficiency and performance of today. Among them, PP-CF20 and PP-CF30 is a composite material that has lately been a rising star in the material scene because to its great performance and broad applications possibilities. Let’s examine now how these materials shine in the domains of consumer electronics, aircraft, sports equipment, and vehicles.

High-strength PP-CF30 for helmets

What is PP-CF?

One product adding carbon fibre to polypropylene is PP-CF, or polypropylene carbon fibre composite. While polypropylene is a lightweight, chemically resistant thermoplastic, carbon fibre itself is renowned for its very great strength and stiffness. Combining these two materials generates the PP-CF series, which has much enhanced stiffness, durability, and strength.

The ideal mix of strength and lightness

Let us first acquaint yourself with PP-CF20 and PP-CF30. Though its strength and stiffness are somewhat poor, PP, or polypropylene, is a lightweight, chemically resistant thermoplastic with high processing qualities. Scientists blended high-strength material, carbon fibre, with PP to generate PP-CF20 and PP-CF30, therefore offsetting this deficiency. PP-CF30 has 30% carbon fibre; PP-CF20 has 20%. While keeping the original lightweight qualities of PP, this change in proportion greatly enhanced the toughness and form of the material.

The wonders of carbon fibre

Long well-known in the domains of aviation, racing, etc., carbon fibre is a material with remarkably great strength and low weight. Combined with PP, it not only increases the mechanical qualities of the material but also its thermal stability. The inclusion of carbon fibre improves the thermal stability of PP-CF20 and PP-CF30, therefore enabling it to retain steady performance in high temperature conditions, which is clearly a great benefit for components needing to operate at severe temperatures.

Simple to handle composite materials

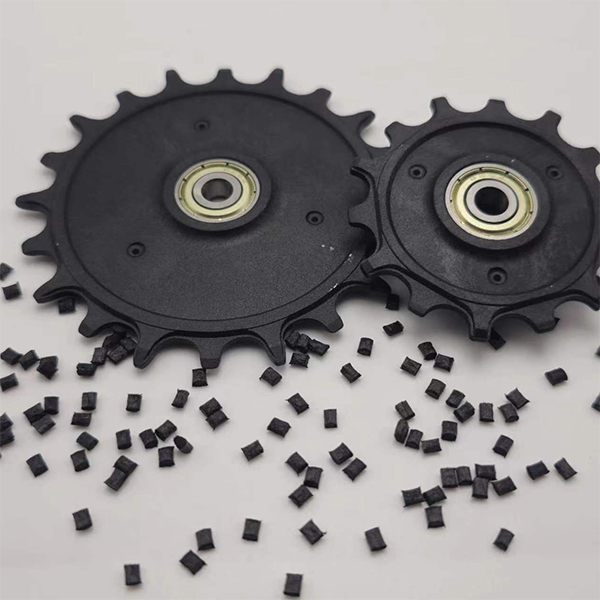

While carbon fibre reinforced polymers are usually challenging to process, PP-CF20 and PP-CF30 maintain PP’s high processability. Common industrial processing techniques like injection moulding and extrusion, which gives designers and engineers more freedom and inventiveness, can thus be developed by them. The lightweight and high-strength properties of PP-CF30 are extensively used in the automotive sector to make bumpers, dashboard brackets, door linings, and other components, thereby lowering the weight of the whole vehicle and increasing fuel economy and carbon emissions reduction.

A future star in the aerospace industry

In the aerospace sector, constant goals are lightweight and high strength. PP-CF30 has evolved into the perfect material for manufacturing structural and interior parts with its lightweight and high-strength properties. When the aircraft is flying at high speed, it can not only lighten its weight and increase fuel economy but also resist different stresses and temperature fluctuations, thereby guaranteeing the safety and performance of the aircraft.

A new sports equipment favourite

PP-CF30’s great strength and durability make it the perfect material for sporting equipment like skis, tennis rackets, bicycle frames, etc. PP-CF30’s chemical resistance and weather resistance only satisfy the necessity for these tools, which must keep performance in many hostile conditions. Imagine that in a violent tennis game your tennis racket must survive several impacts of striking the ball, hence the use of PP-CF30 guarantees the stability and longevity of the racket.

High strength PP-CF5 for manufacturing helmets

Consumer electronics’ lightweight revolution

In the realm of consumer electronics, PP-CF30’s low weight qualities also have great value. The quest of mobility by customers has made lightweighting of structural elements like electronic device housings a major design issue. PP-CF30 not only lightens items but also preserves their durability, which is clearly a huge advantage for electronic equipment aiming at thin and light design and excellent performance.

Infinite possibilities with PP-CF materials

PP-CF20 and PP-CF30, composite materials comprised of carbon fiber and polypropylene, are altering our world with their low weight, high strength, chemical resistance and weather resistance. They not only offer significant promise in the realms of autos, aeroplanes, sports equipment and consumer electronics, but also continue to boost the growth of materials research. With the continuing development of technology, we can expect that PP-CF materials will play their distinctive worth in more areas in the future, bringing more convenience and surprises to our lives and work.

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...