Main benefits of PPA-CF (Polyacrylamide – Carbon Fiber Reinforced Plastic)

PPA-CF (Polyphthalamide Carbon Fiber) combines the high-performance properties of PPA (Polyphthalamide) with the reinforcement of carbon fibers (CF). This results in a material that offers a combination of both high mechanical strength and excellent thermal properties. Below are the main benefits of PPA-CF:

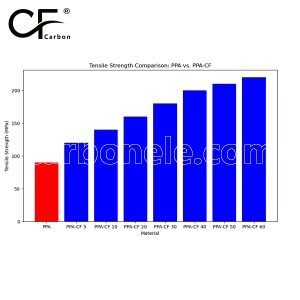

Improved Mechanical Properties

- High Strength and Stiffness: The addition of carbon fiber significantly increases the material’s tensile strength and modulus, making it ideal for applications that require high load-bearing capacity and rigidity.

- Enhanced Impact Resistance: While PPA is already strong, the carbon fiber reinforcement provides better resistance to impacts and mechanical stresses.

Superior Thermal Stability

- High Heat Deflection Temperature (HDT): PPA CF exhibits excellent heat resistance, with the carbon fiber content further improving its ability to withstand high temperatures without deformation.

- Low CTE (Coefficient of Thermal Expansion): The carbon fibers help reduce the expansion or contraction of the material when exposed to temperature variations, which is crucial for maintaining dimensional stability in thermal cycles.

Dimensional Stability

- The carbon fiber reinforcement minimizes the risk of warping, shrinkage, and expansion, ensuring that PPA CF parts maintain their shape and size under both high-temperature and high stress conditions.

Wear and Abrasion Resistance

- Reduced Wear: Carbon fibers help improve the wear resistance of PPA CF, making it suitable for applications involving friction or sliding contacts, such as automotive parts, gears, or bearings.

- Extended Service Life: The added carbon fibers reduce wear and tear, which increases the material’s service life, especially in demanding industrial environments.

Electrical Conductivity

- Enhanced Conductivity: Carbon fiber reinforcement can make PPA CF electrically conductive to a certain degree, which can be useful in applications where static dissipation or EMI shielding is required.

Chemical Resistance

- PPA, in general, offers strong resistance to various chemicals, including oils, fuels, and solvents. The addition of carbon fibers does not significantly affect this property, ensuring PPA CF retains its chemical resistance even in harsh environments.

Lightweight

- While PPA CF has significantly improved mechanical properties compared to standard PPA, it is still relatively lightweight, making it a good choice for applications in industries like automotive, aerospace, and electronics where weight reduction is crucial.

Better Processability

- Injection Molding: PPA CF is highly suited for injection molding, making it easier to process into complex shapes with high precision. This is important in industries that need to produce large volumes of parts efficiently.

- Consistency: Carbon fiber reinforced PPA exhibits better flow during injection molding, providing consistent results with minimal warping and shrinkage.

Electrical and Thermal Conductivity (Selective)

- The carbon fiber can introduce selective electrical and thermal conductivity depending on the fiber content. This can be beneficial in applications like electrical connectors, heat dissipation parts, and high performance structural components.

Environmental Resistance

- UV Resistance: PPA-CF materials tend to resist UV degradation better than non-reinforced polymers, allowing them to perform well in outdoor applications.

- Moisture Resistance: Carbon fiber reinforcement can help minimize the moisture absorption of the material, which is critical in environments with varying humidity.

Common Applications of PPA-CF:

- Automotive: Lightweight, high-strength parts like gears, connectors, and housings that can withstand high temperatures.

- Aerospace: Structural components that require high thermal stability and low weight.

- Electronics: Parts requiring dimensional stability, wear resistance, and electrical conductivity.

- Industrial: Bearings, bushings, and other parts subjected to heavy loads and high temperatures.

If you want to get more information about PPA-CF, you can vist our Youtube.

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...