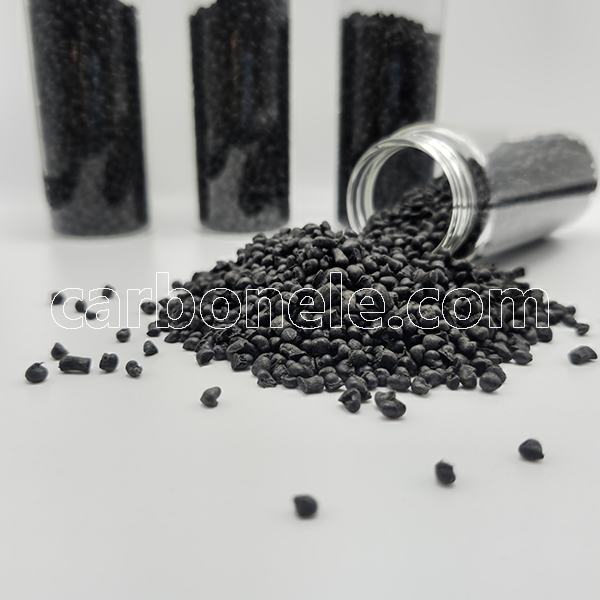

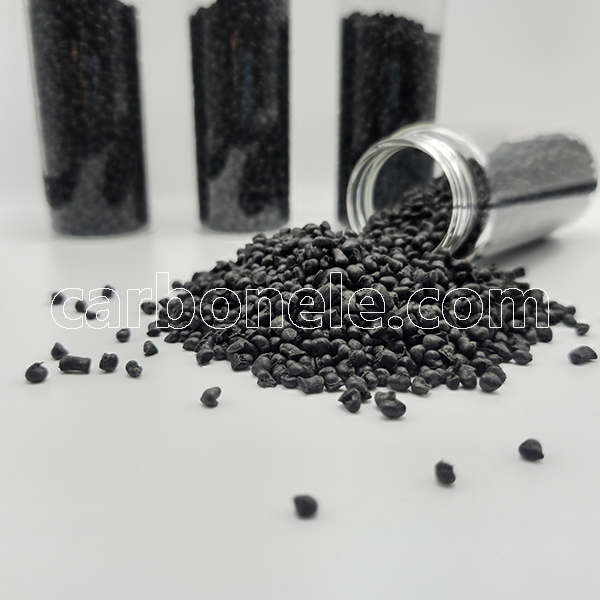

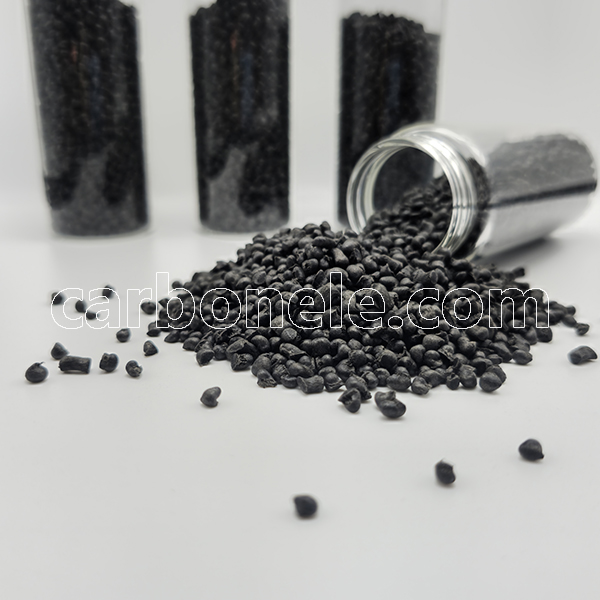

Low Friction Coefficient PPA CF20 Granules

PPA CF20 with a low friction coefficient combines the structural advantages of PPA resin and carbon fiber reinforcement with specific additives or processing techniques to achieve reduced friction characteristics, making it suitable for demanding applications where smooth operation and durability are paramount.

- Model: PPA-CF-BCA2

- Filler: Carbon fiber

- Manufacturer: Yes

- OEM: Acceptable

- Free sample: Available

- Molding process: Injection /extrusion

What’s PPA CF20?

PPA CF20 granules refer to a specific type of composite material composed of Polyphthalamide (PPA) resin blended with 20% Carbon Fiber (CF), typically in granular form. Here are some key aspects and considerations regarding PPA CF20 granules:

1. Composition: PPA CF20 granules consist of PPA resin as the matrix material reinforced with 20% by weight of carbon fiber. This composition is chosen to achieve a balance of mechanical strength, stiffness, and other performance characteristics suitable for various applications.

2. Mechanical Properties: The inclusion of carbon fiber significantly enhances the mechanical properties of PPA resin. Carbon fiber is known for its high tensile strength, stiffness, and resistance to deformation under load. Therefore, PPA CF20 exhibits improved strength and stiffness compared to unfilled PPA resin.

3. Lightweight: Despite the addition of carbon fiber, PPA CF 20 remains relatively lightweight. This characteristic is beneficial for applications where weight reduction is important without compromising on mechanical performance.

4. Applications: PPA CF20 granules are utilized in industries where high-performance materials are required, such as automotive (for structural components, engine parts), aerospace (for lightweight structures), electronics (for housings and connectors), and industrial manufacturing (for machinery and equipment).

5. Processing: PPA CF20 granules are typically processed using injection molding or extrusion techniques to manufacture components and parts with complex geometries. The granular form allows for efficient handling and melting during processing, ensuring uniform distribution of carbon fiber within the PPA matrix.

6. Properties: In addition to enhanced mechanical properties (strength, stiffness), PPA CF20 also offers good chemical resistance, thermal stability, and dimensional stability. These properties make it suitable for applications exposed to harsh environments or fluctuating temperatures.

7. Customization: Manufacturers can tailor the properties of PPA CF 20 granules by adjusting the ratio of PPA resin to carbon fiber content or by incorporating additives to meet specific performance requirements for different applications.

Why to choose a low friction coefficient PPA CF20 granules?

1. Friction Characteristics: The low friction coefficient of PPA CF20 can be attributed to several factors:

– **Carbon Fiber Alignment**: Proper orientation and distribution of carbon fibers within the PPA matrix can reduce frictional forces between sliding surfaces.

– **Surface Smoothness**: Carbon fiber reinforcement often leads to a smoother surface finish, which can help minimize frictional resistance during sliding or rubbing motions.

– Self-lubricating Properties: Some formulations of PPA CF 20 may incorporate additives or modifiers that act as internal lubricants, further reducing friction between contacting surfaces.

2. Applications: PPA CF 20 with a low friction coefficient is particularly advantageous in applications where sliding or moving components require reduced wear, energy efficiency, and smooth operation. Examples include:

– **Automotive**: Bearings, bushings, gears, and sliding components in automotive engines and transmissions.

– **Industrial**: Conveyor systems, machine components, and equipment where friction reduction enhances performance and longevity.

– **Consumer Products**: Household appliances, electronics, and sporting goods where smooth operation and durability are critical.

3. Benefits: Choosing PPA CF20 with a low friction coefficient offers benefits such as improved efficiency, reduced maintenance costs due to lower wear rates, quieter operation, and enhanced reliability in various mechanical systems and applications.

Content Block 1

Morbi iaculis at quam vel faucibus. Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio. Duis vel pulvinar dolor, at lacinia tellus.

Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Suspendisse lacinia quam a elit lobortis tempor

Content Block 1

Morbi iaculis at quam vel faucibus. Ut semper ipsum ex, quis aliquet justo pretium a. Suspendisse scelerisque metus augue, a interdum leo iaculis sed. Vivamus sit amet nunc odio. Duis vel pulvinar dolor, at lacinia tellus.

Pellentesque habitant morbi tristique senectus et netus et malesuada fames ac turpis egestas. Suspendisse lacinia quam a elit lobortis tempor

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.