Lightweight PP CF20 For Engine Covers

PP CF20 is a thermoplastic composite featuring polypropylene with 20% carbon fiber reinforcement. It excels in lightweight strength, heat resistance, corrosion resistance, impact resistance, and processability. Widely used in automotive, electronics, aerospace, and industrial sectors, it offers reliable solutions for high-performance applications.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model No.: PP-CF-BCA2

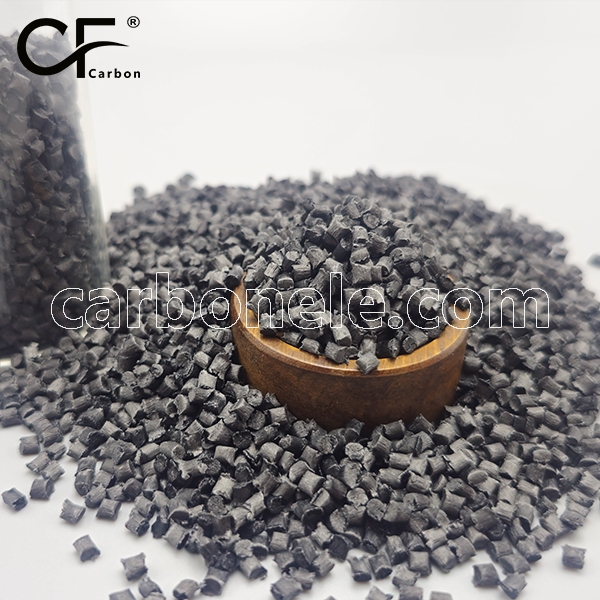

- Reinforcing Filler: Chopped carbon fibers

What’s PP CF20?

PP CF20 typically refers to a material specification, specifically Polypropylene Copolymer with a 20% chalk filler. This type of material is used in various applications where a balance of properties such as stiffness, impact resistance, and cost-effectiveness is required. The addition of chalk (calcium carbonate) as a filler can modify properties like density, stiffness, and dimensional stability of the polypropylene copolymer.

What characteristics does PP carbon fiber 20% exhibit?

PP CF20%, or Polypropylene Carbon Fiber 20% Composite, is a thermoplastic composite material comprising polypropylene as its matrix with 20% carbon fiber reinforcement. It possesses several key characteristics that make it outstanding in various applications:

1. Lightweight and High Strength: PP CF20% exhibits an excellent strength-to-weight ratio. The addition of carbon fibers significantly enhances the material’s strength and stiffness while maintaining a relatively low density, making it an ideal choice for manufacturing lightweight components.

2. Excellent Heat Resistance: Due to the high thermal stability of carbon fibers, PP CF20% demonstrates good heat resistance, suitable for applications requiring prolonged exposure to high temperatures.

3. Superior Corrosion Resistance: The inherent chemical stability of polypropylene, combined with carbon fiber reinforcement, provides PP CF20% with excellent resistance to various chemicals and corrosive environments.

4. Excellent Impact Resistance: The reinforcing effect of carbon fibers significantly improves the material’s impact resistance, enabling it to withstand sudden loads and impacts, thereby reducing the risk of component damage due to accidental collisions.

5. Excellent Processability: PP CF20% exhibits good processability and moldability, allowing for the manufacture of complex-shaped parts and components through processes such as blow molding and injection molding, while maintaining material consistency and stability.

In summary, PP CF20% is widely used in industries such as automotive, electronics, aerospace, and industrial equipment due to its lightweight, high strength, heat and corrosion resistance, excellent impact resistance, and good processability. It provides reliable material solutions for various engineering applications. With ongoing technological advancements and expanding application areas, PP CF20% is poised to play an increasingly important role in the field of composite materials.

Specific applications in the automotive industry

PP CF20 (Polypropylene with 20% Carbon Fiber Reinforcement) manufactured by Carbon Xiamen New Material has emerged as a game-changer, offering numerous benefits and innovative solutions.

One notable application is in the manufacturing of lightweight engine covers. Traditionally, these covers were made from heavier materials, adding unnecessary weight to the vehicle and affecting fuel efficiency. However, by using PP CF20, automakers have been able to significantly reduce the weight of the engine covers without compromising on strength and durability.

The carbon fiber reinforcement within the polypropylene matrix provides enhanced mechanical properties, allowing the covers to withstand the high temperatures and vibrations within the engine compartment. This ensures long-term performance and reliability.

Another area where PP CF20 has made a significant impact is in the production of interior components such as dashboard structures. The material’s combination of strength and lightweight nature helps to improve the overall safety of the vehicle while also contributing to better fuel economy.

For example, a leading automotive manufacturer replaced the conventional plastic dashboard frame with a PP CF20 component. This not only reduced the weight of the vehicle but also improved the structural integrity of the dashboard, providing better protection to the occupants in the event of a collision.

PP CF20 is being used in suspension parts. The enhanced stiffness and fatigue resistance offered by the carbon fiber reinforcement enable these parts to handle the continuous stress and strain of the vehicle’s movement, improving the handling and ride quality.

PP CF20 has proven to be a valuable material in the automotive sector, enabling manufacturers to create lighter, stronger, and more fuel-efficient vehicles without sacrificing safety or performance. Its continued development and application are likely to drive further advancements in automotive engineering.

Please click here to learn more about CFRTPs by watching videos, or visit our offical homepage to pick up to more information on carbon fiber reinforced thermoplastic polymers.

Strict Quality Control System

- A complete quality control process has been established. From raw material procurement to product delivery, every link is subject to strict testing and monitoring to ensure the stability and reliability of product quality. Taking the PA6 CF product as an example, its various performance indicators are better than industry standards, winning high trust from customers.

Advanced Laboratory Equipment

1. Performance Testing Equipment Equipped with universal material testing machines, dynamic mechanical analyzers (DMA), thermogravimetric analyzers (TGA), differential scanning calorimeters (DSC), thermal conductivity testers, electrical property testers, etc., to comprehensively evaluate various properties of the materials. 2. Microstructure Analysis Instruments Including scanning electron microscopes (SEM), transmission electron microscopes (TEM), X-ray diffraction analyzers (XRD), etc., for observing and analyzing the microstructure and phase distribution of the materials.

Excellent After-sales Service Team

Carbon (Xiamen) New Material offers all-round, prompt, and professional after-sales support. A dedicated team responds within 24 hours. They solve problems remotely or on-site and provide installation and maintenance training. Feedback is used to improve service. The company also establishes long-term relationships with customers by providing regular maintenance checks and updates, ensuring the longevity and optimal performance of its products.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.