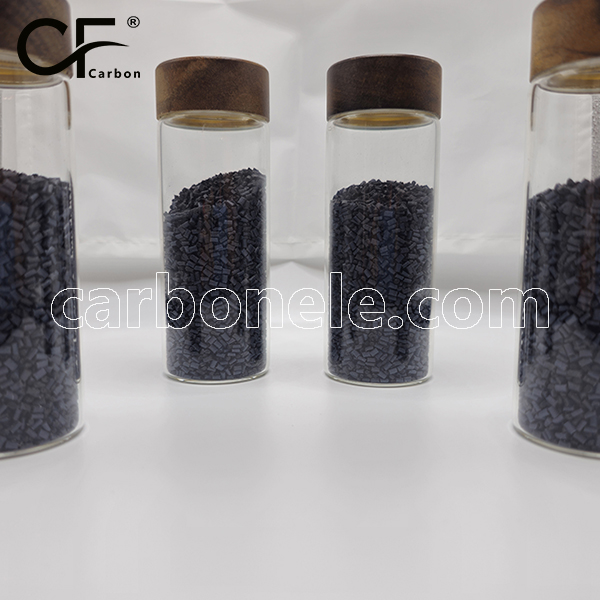

High Temperature Resistance PPS CF20 for Auto Parts

In the automotive industry, material performance affects vehicle safety. PPS CF20 is favored for its heat and strength, being used in engine heat shields and underbody plates. It improves engine reliability and vehicle safety. Carbon (Xiamen) New Material supplies high-quality PPS CF20, enhancing driving experience and industry development.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model Number: PPS-CF-BCA2

What’s PPS CF20?

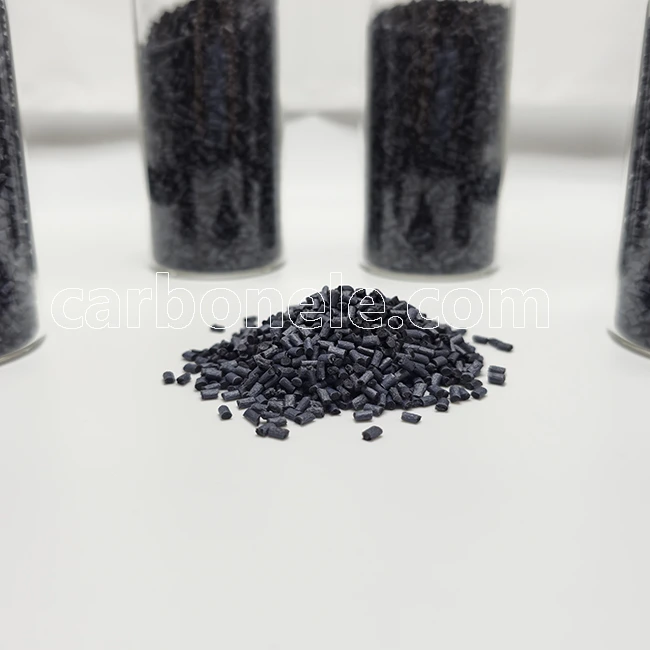

PPS CF20 is a type of composite material. It combines PPS resin with 20% carbon fibers, offering high strength, heat resistance and other excellent properties.

1. High Temperature Stability:

– PPS CF20% exhibits excellent thermal stability, maintaining its physical properties in high-temperature environments. Its continuous use temperature typically reaches up to 250°C, with short-term use temperatures up to 300°C.

2. Outstanding Mechanical Properties:

– The inclusion of carbon fibers significantly enhances the material’s rigidity and strength, providing high tensile strength and impact resistance. Generally, the mechanical strength of this material is much higher than that of unreinforced PPS.

3. Excellent Chemical Resistance:

– PPS with 20% carbon fiber filled offers high resistance to most chemicals, including acids, bases, and solvents, making it suitable for use in harsh chemical environments.

4. Low Water Absorption:

– This material has an extremely low water absorption rate, which helps maintain its mechanical performance and dimensional stability, especially in humid conditions.

5. Good Electrical Insulation Properties:

– PPS CF20 provides excellent electrical insulation, making it suitable for electrical and electronic applications and effectively preventing electrical failures.

6. Good Dimensional Stability:

– Due to its low thermal expansion coefficient, PPS with 20% CF filled maintains good dimensional stability with temperature changes, which is particularly important for precision parts.

These properties make PPS + CF20 advantageous for applications in extreme conditions involving high temperatures, chemical exposure, and mechanical stress.

An Application Case in Auto Parts

In today’s automotive manufacturing industry, the performance of materials directly affects the safety and outstanding performance of vehicles. PPS 20%CF carbon fiber reinforced composite materials are gradually becoming the favorite of the industry due to their excellent high-temperature resistance and high-strength characteristics.

Recently, the world-renowned automotive manufacturer boldly introduced 20% CF PPS in its new high-performance sports car. The engine heat shield and underbody protection plate of this sports car are both made of PPS + CF20% material. The engine heat shield effectively isolates the heat generated by the engine under high-temperature operating conditions, preventing the erosion and damage of high temperatures to other components. Due to the superior high-temperature resistance of PPS CF20, this application greatly improves the reliability of the engine and ensures the stability of the vehicle in extreme driving environments.

At the same time, the use of 20%CF PPS material for the underbody protection plate also brings a significant safety improvement. The high-strength characteristics of this material enable the protection plate to effectively resist external impacts such as stones and road debris, reducing potential damage to the underbody components. This not only improves the durability of the vehicle but also provides additional protection during high-speed driving or in harsh road conditions.

Carbon (Xiamen) New Material as the supplier of PPS + CF20%, ensures the consistency and high quality of the materials. During the production process, the company strictly controls every link, from raw material procurement to final product testing, to ensure that each piece of 20% carbon fiber reinforced PPS meets the strictest performance standards. Its high-quality materials not only enhance the product performance but also bring consumers a safer and more reliable driving experience.

Through this technological innovation, the application of PPS + 20%CF in the field of automotive manufacturing shows its great potential and also provides valuable experience for the application of materials in other high-demand fields in the future. The successful application of this material undoubtedly injects new impetus into the development of the automotive industry.

How to Control the Quality of PPS CF20 Effectively?

1. Stringent raw material control: Select high-quality carbon fibers and PPS resins as starting materials, ensuring their purity, fiber length and the performance indicators of the resin meet the requirements.

– For example, conduct detailed inspections on carbon fibers to ensure their tensile strength and modulus of elasticity meet the standards.

2. Optimized manufacturing process: Adopt advanced and precisely controlled production processes, such as injection molding, compression molding or hot-press molding.

– For instance, precisely control the parameters of temperature, pressure and time during the molding process to achieve good fiber distribution and resin infiltration.

3. Strict quality inspection: Conduct comprehensive quality inspections at all stages of production, including raw material inspection, process inspection and finished product inspection.

– Such as using professional equipment to test the mechanical, thermal and chemical properties of the composite materials.

4. Employee training: Ensure that operators have rich knowledge and skills and strictly follow operating procedures.

– Regularly organize training to keep employees informed of the latest production technologies and quality control requirements.

5. Environmental control: Maintain a clean, dry and suitable temperature in the production environment to avoid the influence of external factors on the material performance.

6. Continuous research and development and improvement: Continuously explore new formulations and processes to enhance the performance and quality of the materials.

Learn more about carbon fiber filled PPS compounds, please click here or watch videos on YouTube.

Should you be interested in PPS CF20 compounds or other CFRTPs, please contact me without hesitation.

Features of Short Carbon Fibers

1. Enhanced mechanical strength, increasing the durability of materials. 2. Lightweight, reducing the overall weight of products. 3. Good electrical conductivity, suitable for electronic applications. 4. Chemical resistance, enabling use in harsh environments. 5. Improved thermal stability, allowing for higher temperature operation.

R&D Team

Carbon (Xiamen) New Material has an outstanding R&D Team. Comprising experts and innovators, they are passionate and dedicated. Their diverse skills drive cutting-edge research, creating revolutionary materials. The team's synergy leads to remarkable achievements.

Laboratory Scenario

It is equipped with advanced experimental equipment and instruments for the research, development, testing and analysis of materials. It has professional technicians with professional knowledge and skills in related fields. It pays attention to the control of the experimental environment, such as temperature, humidity and cleanliness, to ensure the accuracy and reliability of the experimental results. It follows strict experimental processes and quality control standards to guarantee the quality and performance of the products. It may carry out various experimental projects, including material synthesis, performance testing and process improvement, to continuously promote the research and development and innovation of new materials.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.