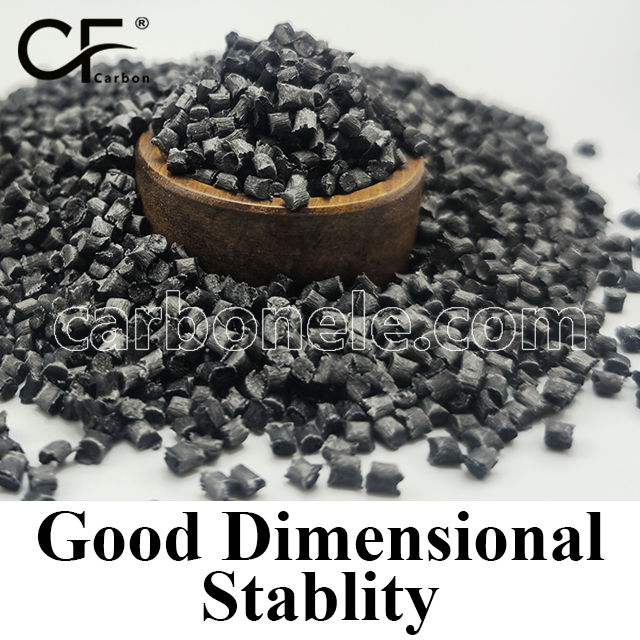

High Strength TPU CF20 for Snowboards

The performance characteristics of TPU CF20 include: High strength, providing solid support. Significant lightweight. Excellent shock absorption. Outstanding wear resistance. Unique elasticity for terrain adaptation. Good temperature resistance. Strong chemical resistance for stable performance.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model No.: TPU-CF-BCA2

What does TPU CF20 feature?

The performance characteristics of TPU CF20 mainly include the following aspects:

1. High strength: It has outstanding strength far exceeding that of ordinary materials, providing a solid and reliable structural support for related products.

2. Significant lightweight characteristics: Significantly reduces the weight of the product while ensuring performance, contributing to the improvement of the overall portability and flexibility.

3. Excellent shock absorption capacity: It can effectively absorb and buffer the energy brought by external shocks, ensuring safety and stability during use.

4. Outstanding wear resistance: It can withstand frequent friction and wear, prolonging the service life of the product.

5. Unique elastic characteristics: Enable the product to adapt well to various complex and diverse terrains and maintain stable performance in different environmental conditions.

6. Excellent temperature resistance: It can maintain stable physical and chemical properties within a wide temperature range, and can operate normally in both high and low temperature environments.

7. Strong chemical resistance: It has excellent resistance to a variety of chemical substances and is not easily subject to chemical corrosion, thereby maintaining stable and reliable performance in various chemical environments.

An application case in the sports field

Carbon fiber reinforced thermoplastic TPU (TPU CF20) is gradually becoming a disruptive material in modern industrial design,, bringing about a revolution in performance and application. A notable practical application case comes from Carbon (Xiamen) New Material, which successfully applied TPU CF20 to the manufacturing of high-end sports equipment.

The recently launched 20%CF TPU thermoplastic material by Carbon (Xiamen) New Material has played a significant role in the manufacturing of high-performance ski boards due to its outstanding strength and lightweight characteristics. The application of TPU CF20 on such ski boards demonstrates its excellent shock absorption capacity and wear resistance. The core layer of this ski board is made of TPU 20%CF, which not only effectively reduces the overall weight of the ski board but also significantly enhances its impact resistance, enabling athletes to achieve a more stable performance in complex snowy environments.

After adopting TPU CF20, ski board manufacturers reported that the lifespan of the ski boards has significantly increased, and at the same time, their sports performance has also been significantly improved. Due to the elastic characteristics of TPU CF20, this ski board can better adapt to various terrains, providing a smoother and more comfortable gliding experience. In addition, the temperature resistance and chemical resistance of the TPU 20% CF material make this ski board perform stably even in extreme climates, further expanding its application scope.

The introduction of the TPU CF20% material has brought new possibilities to the manufacturing of high-end sports equipment. Carbon (Xiamen) New Material Company, through this innovation, has demonstrated its leading position in the field of high-performance composite materials. Ski enthusiasts will benefit from the excellent performance brought by this material and enjoy a more extreme sports experience.

Difference between CF20 TPU and common TPU

The material composition is different. TPU CF20 contains 20% carbon fiber reinforcement, while common TPU does not contain carbon fiber.

In terms of performance, due to the addition of carbon fiber, the strength of TPU CF20 is significantly improved, while the strength of common TPU is relatively low.

In terms of weight, TPU CF20 is usually lighter to achieve lightweight, while common TPU is heavier.

In terms of wear resistance, TPU CF20% performs better, while common TPU is slightly inferior.

In addition, the impact resistance of TPU + CF20 is better than that of common TPU, and it can better cope with external impacts.

TPU CF 20 is superior to common TPU in multiple performance aspects.

Read more information on Carbon fiber reinforced thermoplastic TPU composites or other CF filled thermoplastic compounds, please click here or watch relevant videos on our YouTube account.

If you are interested in 20% carbon fiber combined TPU resins, please do not hesitate to contact us at any time.

TPU & TPU CF20

The differences between TPU CF20 and common TPU: Composition varies. TPU CF20 has 20% carbon fiber, not in common TPU. Performance-wise, TPU CF20 has higher strength. It's lighter and more wear-resistant. Also, its impact resistance is better. In short, TPU CF20 outperforms in many aspects.

Classification of CF

Carbon fibers can also be classified as: High-temperature treated carbon fibers (HTT): Associated with high modulus types of fibers, requiring a final heat treatment temperature above 2000°C. Intermediate-temperature treated carbon fibers (IHT): The final heat treatment temperature is typically equal to or above 1500°C and is often associated with high-strength type fibers. Low-temperature treated carbon fibers (LHT): The final heat treatment temperature does not exceed 1000°C. These materials have lower modulus and strength.

Advanced Laboratory

The carbon fiber reinforced thermoplastic composites laboratory of Carbon (Xiamen) New Material Co., Ltd. is equipped with advanced instruments. It has a professional research team dedicated to R&D. With synthesis and detection equipment, it follows scientific processes and emphasizes safety. The achievements help the company and advance the industry.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.