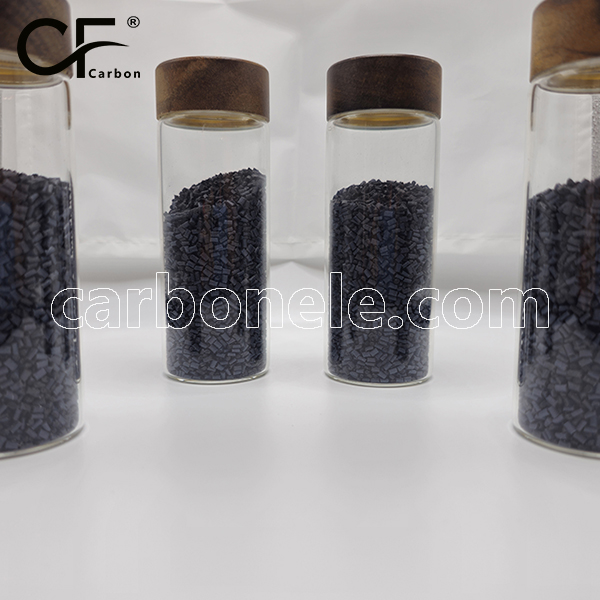

High Strength Talc Filled PPS CF Pellets PPS-CF-Talc

High Strength Talc Filled PPS CF Pellets combine PPS, CF and talc. CF boosts strength for heavy loads, talc improves stability and flow. Widely used in electronics, automotive etc., it’s a great engineering choice.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model: PPS-CF-BCA3

- Fillers: Carbon fiber

What’re High Strength Talc Filled PPS CF Pellets?

High Strength Talc Filled PPS CF Pellets are a specialized engineering material with notable features and diverse applications.

PPS (Polyphenylene Sulfide) is renowned for its good chemical resistance, thermal stability, and inherent mechanical strength. When carbon fiber (CF) and talc are incorporated into it, its performance is elevated to a new level.

The addition of carbon fiber plays a vital role in enhancing the strength. It reinforces the structure of the pellets, increasing their tensile strength and making them capable of withstanding heavy loads. This allows the pellets to be used in applications where high structural integrity is demanded.

Talc, on the other hand, brings its own advantages. It can improve the dimensional stability of the material, reducing shrinkage during processing and enhancing the surface finish of the final products. Moreover, it also contributes to better flow properties during manufacturing processes.

These pellets are widely utilized in multiple industries. In the electronics industry, they can be used for making casings that need to be both strong and have good heat dissipation. In the automotive field, they are suitable for parts like brackets and small structural components, ensuring durability and stability under various conditions. Overall, High Strength Talc Filled PPS CF Pellets are a valuable choice for many engineering projects.

| Industry | Application Parts | Advantage Demonstration |

|---|---|---|

| Electronics Industry | Equipment Casings | High strength for protection, good heat dissipation for stable operation of equipment. |

| Automotive Industry | Brackets, Small Structural Components | Ensures durability, maintains structural stability, adapts to various working conditions. |

| Mechanical Manufacturing | Some Load-bearing Structures | Can bear heavy loads, has dimensional stability, facilitates processing and assembly. |

If you’d love to get more on carbon fiber materials – Talc Filled PPS CF Pellets or more CFRTPs, please click here or directly contact Carbon New Material.

Contact Us

If you want to obtain information such as product specifications, performance, and price, choose a suitable product according to your own needs. Meanwhile, you can ask the manufacturer to provide samples for testing to ensure that the material meets your usage requirements. If you are interested in purchasing this composite material, please contact the manufacturer Carbon (Xiamen) New Material directly.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.