High Strength PC CF20 for Electric Bicycle Frames

PC CF20 developed by Carbon (Xiamen) New Material is ingeniously applied in the frame of new electric bicycles in urban transportation, offering remarkable advantages like excellent strength, lightweight, and outstanding heat and corrosion resistance, significantly enhancing their performance and reliability.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model Number: PC-CF-BCA2

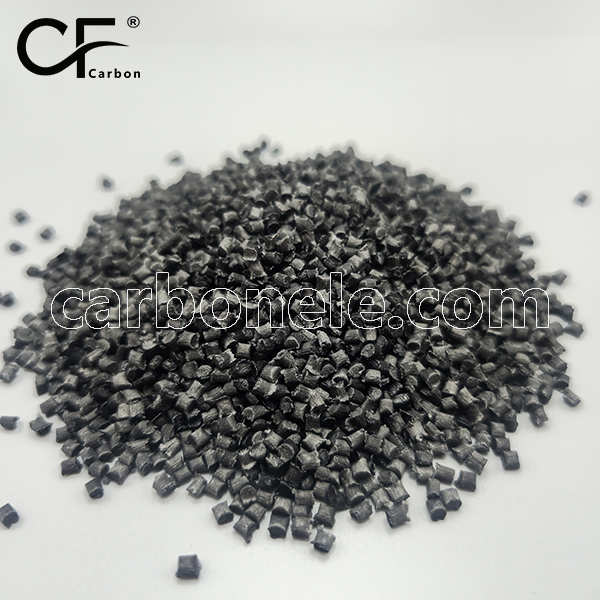

What’s PC CF20?

The 20% carbon fiber reinforced polycarbonate composite material (PC CF20) is a material composed of polycarbonate as the matrix and 20% carbon fiber as the reinforcement.

It has many excellent properties. In terms of mechanical properties, its tensile and flexural strengths are greatly enhanced, significantly stronger than pure polycarbonate (tensile strength of about 63 MPa, flexural modulus of about 2300 MPa). The notch impact strength first increases and then decreases with the increase of carbon fiber, and there is a carbon fiber content value at which the impact strength reaches the maximum. Compared with glass fiber reinforced polycarbonate under the same conditions, its other properties are better.

This material also increases antistatic properties. When the carbon fiber content is 10%, the surface resistivity can reach 9.0×10 ω/sq, and it can be used as an antistatic material. In addition, the addition of carbon fiber improves the processability of polycarbonate, which can significantly improve its viscosity and fluidity, but as the carbon fiber content increases, the fluidity will gradually decrease.

This composite material is widely used in aerospace and military fields, such as low outgassing components, components resistant to space debris impact, components resistant to space radiation, etc.; it is also used in the manufacture of special parts; it can also be used in products such as tent poles and golf bag poles in the field of sports and leisure.

Its specific properties may vary due to factors such as production processes and other added components. In practical applications, it is necessary to select the appropriate material and ratio according to specific needs and usage environments.

Application of PC CF20 in New Electric Bicycles

In the bustling and noisy urban transportation field, the PC 20%CF carefully developed by Carbon (Xiamen) New Material has been ingeniously applied to the frame manufacturing of new electric bicycles, showing a series of remarkable advantages.

The PC CF20% has extraordinary and excellent strength characteristics. Compared with traditional materials, it can withstand greater impact force and pressure. Even in the complex and changeable driving process, encountering extreme situations such as severe bumps and unexpected collisions, the frame can be tough and hardly deformed or damaged. This undoubtedly builds a solid safety barrier for cyclists. For example, when cyclists rush over raised road bumps at high speed or unfortunately fall accidentally, the frame can still maintain its original complete structure, strongly avoiding various hidden dangers that may endanger the personal safety of cyclists.

The lightweight characteristic of PC 20% CF can be regarded as a dazzling highlight. This feature significantly reduces the weight of the entire electric bicycle, allowing cyclists to experience unprecedented ease and flexibility when manipulating the vehicle. Especially in the urban road environment where traffic is congested and frequent stops and sharp turns are required, its advantages are even more prominent. For example, for female cyclists with relatively weak strength and elderly cyclists with slightly slower reactions, they can also control the vehicle effortlessly and freely shuttle through the streets and alleys.

PC CF20 also has outstanding heat resistance. In the scorching hot summer, even if long-term riding causes the frame temperature to continue to rise, it can still firmly maintain stable mechanical properties and will not show any softening or strength decline. This means that even in long-distance riding in extremely hot weather, the frame can remain highly reliable from beginning to end.

In addition, its good corrosion resistance is even more outstanding. The frame can stubbornly resist the erosion of rainwater, the infiltration of moisture, and the erosion of various chemical substances. Whether riding in the rainy and humid season or in coastal areas with a high salt content, the frame can consistently maintain a good appearance and excellent performance over a long period of time, greatly reducing maintenance costs and maintenance frequency.

To sum up, the ingenious application of PC CF20 in the frame of electric bicycles, with its unparalleled strength, lightweight and convenient lightweight, stable and reliable heat resistance and indestructible corrosion resistance and other advantages, has brought a revolutionary qualitative improvement to the overall performance and reliability of electric bicycles.

Learn more about PC Carbon Fiber compounds, please click here. If you would like to watch videos about CFRTPs, please visit our YouTube.

Should you have any interest in this type of composites, please don’t hesitate to contact us, please.

What're PC Resins?

PC resins, or polycarbonate resins, are a type of thermoplastic polymer. They are known for their high strength, toughness, and transparency. PC resins have excellent heat resistance, allowing them to withstand high temperatures without significant degradation. They also offer good electrical insulation properties and are resistant to chemicals and UV radiation. These characteristics make PC resins widely used in various industries, such as electronics, automotive, construction, and healthcare, for manufacturing components like lenses, shields, and housings.

Characteristics of CF

1. High Strength: Chopped carbon fiber provides exceptional tensile strength, making it suitable for reinforcing materials. 2. Low Weight: It is lightweight compared to many traditional reinforcing materials while maintaining high performance. 3. Excellent Thermal Conductivity: Helps in dissipating heat efficiently, making it useful in applications where heat management is crucial. 4. Chemical Resistance: Resistant to a wide range of chemicals, ensuring durability in harsh environments. 5. Electrical Conductivity: Can provide electrical conductivity, useful in applications where this property is needed. 6. Dimensional Stability: Offers good dimensional stability, reducing the risk of warping or distortion.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.