High Strength PA66-CF60 for Suspension System

PA66-CF60 has high strength (about 70% higher tensile strength than standard nylon 66), is lightweight due to high carbon fiber content, has excellent thermal resistance up to 230°C, outstanding chemical resistance, good electrical insulation for safety in electronic devices, low water absorption for stable performance in humid environments, and good processability.

- Model number: PA66-CF-BCA6

- Brand: CARBONELE

- Base resin: Nylon 66

- Reinforcing filler: Carbon fiber

- Free samples: 3-25kgs

- Molding process: Injection/extrusion molding

Introduction to PA66-CF60

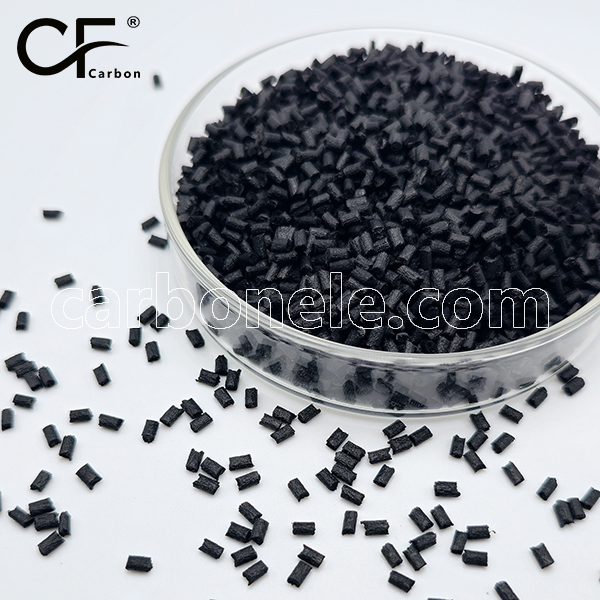

PA66-CF60 is a high-performance thermoplastic composite material, utilizing nylon 66 as the base and 60% short carbon fibers as the filler. This material demonstrates outstanding mechanical properties, thermal stability, and chemical resistance, making it widely applicable across various industries, particularly in fields that require high strength and durability.

Composition

1. Base Material: Nylon 66 (PA66) provides excellent wear resistance and thermal stability, serving as a solid foundation for the composite material.

2. Filler Material: The addition of 60% short carbon fibers significantly enhances the strength and rigidity of the material, markedly improving its tensile and flexural strength.

Performance Advantages

1. High Strength: The tensile strength of PA66-CF60 is approximately 70% higher than that of standard nylon 66, allowing it to withstand greater external forces.

2. Lightweight: The high carbon fiber content enables the material to achieve significant weight reduction while maintaining strength, making it suitable for lightweight design requirements.

3. Excellent Thermal Resistance: With a heat distortion temperature of up to 230°C, this material is well-suited for high-temperature working environments.

4. Outstanding Chemical Resistance: It shows good resistance to various chemicals, extending its service life.

5. Good Electrical Insulation: In electronic devices, it effectively prevents leakage and short circuits, enhancing safety.

6. Low Water Absorption: The material maintains stable performance in humid environments, minimizing performance degradation due to moisture absorption.

7. Good Processability: As a thermoplastic, this material is easy to mold and process, making it suitable for mass production.

Application Fields

PA66-CF60 is widely used in automotive, electronics, machinery, and aerospace sectors, particularly suitable for applications requiring high strength and high-temperature resistance.

Successful Use in Automotive Components

In automotive manufacturing, the use of lightweight and high-strength materials is crucial. The PA66-CF60 composite material developed by Carbon (Xiamen) New Material has been applied in the suspension system of a new electric vehicle, bringing significant breakthroughs to the automotive industry.

The goal of this project was to replace traditional metal materials with PA66-CF60 to reduce the weight of the suspension system while enhancing its strength. Through precise calculations and testing, engineers found that using PA66-CF60 resulted in a 30% weight reduction of the suspension system, while flexural strength increased by approximately 60%. This significant weight reduction not only improved the vehicle’s range but also enhanced driving stability.

In actual road tests, the suspension system performed excellently in high-temperature and humid environments, showing no signs of deformation or degradation. After prolonged performance evaluations, the low water absorption and good chemical resistance of the material ensured the reliability of the suspension system under various environmental conditions.

The successful implementation of this project provided the automotive manufacturer with a competitive edge in a fiercely competitive market and offered new material options for future electric vehicle designs. By utilizing PA66-CF60, Carbon (Xiamen) New Material helped clients achieve a perfect combination of performance and efficiency, contributing to the sustainable development of the automotive industry. With the growing demand for high-performance materials, PA66-CF60 is expected to be applied in more automotive components.

If you would like to learn more about carbon fiber filled NYLON composites, please click here.

The performance of carbon fiber reinforced and modified thermoplastic composite raw materials will vary due to factors such as different matrix resins, the content and type of carbon fibers, and production processes. If you want to know the specific performance, please contact us directly.

Get to Learn More

Thermoplastic composite materials produced by different manufacturers may have different emphases and variations in performance. The performance of carbon fiber reinforced and modified thermoplastic composite raw materials will vary due to factors such as different matrix resins, the content and type of carbon fibers, and production processes.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.