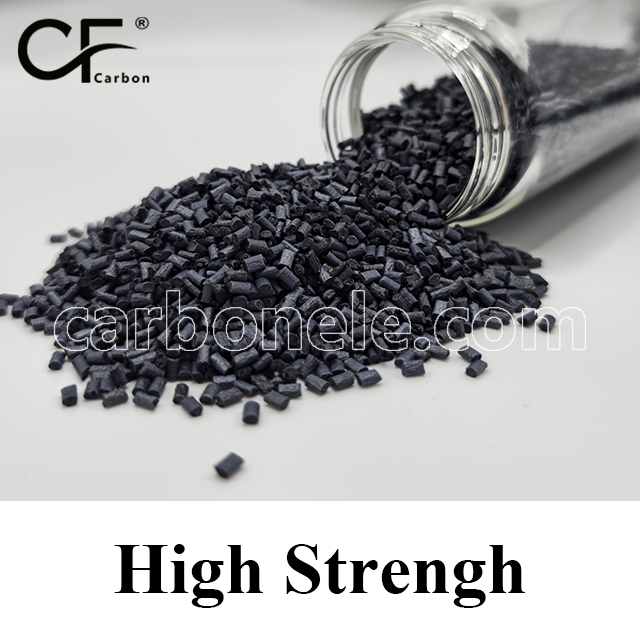

High Quality Weather Resistance TPU CF10 Composites

TPU CF10 is an innovative composite. It combines TPU’s flexibility with 10% carbon fibers’ high strength. It has excellent wear, impact and chemical resistance. With good stability and low-temperature flexibility, it suits various conditions. Outstanding in mechanical and thermal properties, it’s ideal for high-quality products, used in sports and auto parts.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model number: TPU-CF-BCA1

What’re TPU CF10% compounds?

TPU CF10 is an advanced composite material. It is composed of thermoplastic polyurethane (TPU) reinforced with 10% carbon fibers. It possesses features such as high strength, wear resistance, anti-twist property, and good rebound performance. It performs exceptionally well in manufacturing high-performance products like running shoe soles, enhancing the performance and durability of the products.

TPU + 10% CF composites in running shoe soles

10% carbon fiber reinforced TPU composite TPU CF10% has shown remarkable characteristics and broad application prospects in today’s era of pursuing high-performance materials, .

In sports equipment manufacturing enterprises, TPU CF10 has found its application. These enterprises have always been committed to providing top-level equipment for professional athletes to enhance their performance and comfort.

To manufacture a new type of high-performance running shoe sole, they chose TPU CF10 composites. The high strength and excellent wear resistance of this material enable it to withstand the long-term and high-intensity running impact and friction. At the same time, the addition of carbon fibers gives the sole good anti-twist and rebound performance, allowing athletes to feel stable support and efficient energy feedback at every step.

Moreover, TPU CF10 also has good weather resistance and anti-aging performance, which can maintain stable performance whether in hot summer or cold winter.

It is worth mentioning that this excellent material is elaborately developed and produced by Carbon (Xiamen) New Material. With their advanced technology and strict quality control, they ensure the excellent quality of TPU CF10.

Once this running shoe was launched, it was loved and praised by a large number of athletes. It not only improves the athletes’ sports performance but also brings them a more comfortable running experience. It is believed that in the future, the 10% carbon fiber reinforced TPU composite TPU + CF10 will exert its unique advantages in more fields and bring more convenience and surprises to technological innovation and people’s lives.

Benefits of 10% carbon fiber filled TPU resins in running shoe soles

For the manufacture of a new type of high-performance running shoe sole, they chose TPU CF10 without hesitation. This material demonstrates astonishing high strength, capable of easily withstanding the tremendous impact force and continuous friction generated by athletes during long-term and high-intensity running. With each contact of the sole with the ground, it can tenaciously cope without obvious wear or deformation.

Not only that, the integration of carbon fibers endows the sole with outstanding anti-twist performance. During complex and diverse running movements, the sole can flexibly adapt to various twists and rotations of the foot, providing stable and consistent support for athletes and effectively reducing the risk of injury.

Meanwhile, its rebound performance is extremely excellent. When athletes take each step, the sole can quickly store and release energy, converting the impact force into forward propulsion, thereby significantly improving running efficiency and reducing physical energy consumption.

Furthermore, TPU CF also has excellent weather resistance. Whether in the sweltering heat of midsummer, the sole will not become soft or deformed due to high temperatures, affecting performance; or in the bitter cold of winter, it will not become stiff or brittle due to low temperatures. It always maintains stable elasticity and toughness, providing reliable guarantee for athletes’ training and competitions under various climatic conditions.

The anti-aging performance is also a significant highlight. After long-term use and frequent friction, the sole can still maintain its original performance and appearance, without aging, cracking and other problems, greatly extending the service life of the running shoes and saving athletes the cost of replacing equipment.

If you’re interested in this type of materials, please feel free to contact us.

Read more info on TPU reins with 10% carbon fiber combined, please click here.

TPU in Shoe Soles

TPU has become a popular choice for shoe soles. It offers several advantages. TPU resins provide excellent cushioning, reducing the impact on feet during walking or running. It is highly durable and resistant to wear and tear. Also, TPU soles offer good traction, preventing slips. The flexibility of TPU allows for a comfortable fit. TPU in shoe soles enhances performance and comfort for users.

Short Carbon Fiber Features

1. High Strength: Short carbon fibers possess remarkable tensile and compressive strength, allowing for reinforcement in various materials. 2. Lightweight: Despite their strength, they contribute minimally to the overall weight of the composite. 3. Thermal Conductivity: They offer good heat transfer capabilities, making them suitable for applications where thermal management is crucial. 4. Electrical Conductivity: Some short carbon fibers can provide electrical conductivity, opening up possibilities in electronics and other related fields.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.