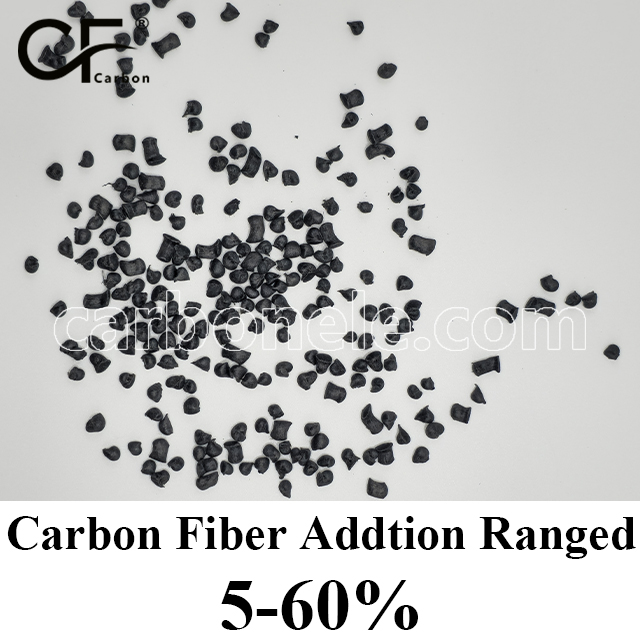

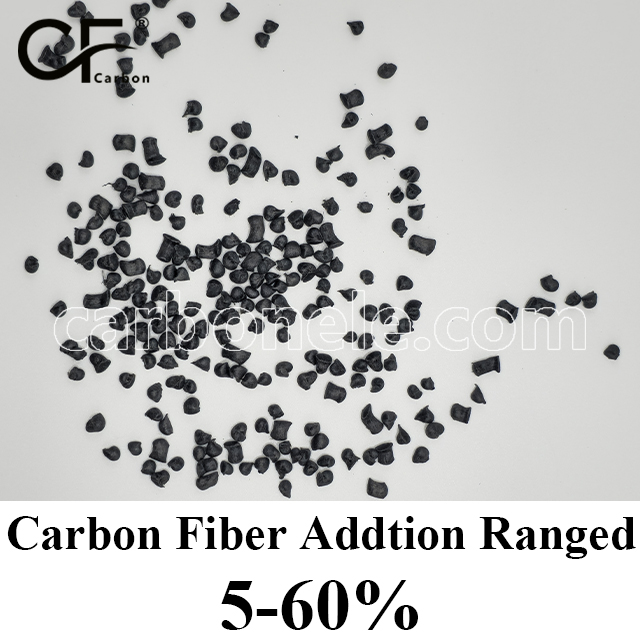

High Impact Resistance PC CF10 10% Carbon Fiber Polycarbonate Resins

PC CF10 is a polycarbonate composite with 10% carbon fibers. It has advantages like high strength, good heat resistance, low expansion, conductivity, wear resistance, and is lightweight. It’s chosen for better performance and durability over similar materials.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model Number: PC-CF-BCA1

What is PC CF10?

The 10% carbon fiber filled polycarbonate resins consist of polycarbonate as the base material and 10% of carbon fibers as the reinforcing component. Polycarbonate is a thermoplastic polymer known for its high strength, transparency, and heat resistance. The addition of 10% carbon fibers enhances the mechanical properties such as strength, stiffness, and impact resistance of the polycarbonate. The carbon fibers provide reinforcement, making the material more suitable for applications that require high performance and durability.

Why to choose 10% carbon fiber filled polycarbonate resins?

PC CF10 is a polycarbonate (PC) composite material containing 10% carbon fibers. Compared with other similar materials, it has the following advantages:

– High strength and rigidity: The addition of carbon fibers significantly enhances the strength and rigidity of PC, enabling it to withstand higher loads and stresses.

– Good heat resistance: PC itself has relatively high heat resistance, and the presence of carbon fibers further improves the thermal stability of the material, allowing it to maintain performance at higher temperatures.

– Low expansion coefficient: The low thermal expansion coefficient of carbon fibers helps reduce the dimensional changes of PC CF10 when the temperature changes, improving the dimensional stability.

– Good electrical conductivity: The electrical conductivity of carbon fibers gives PC CF10 certain conductive properties, which can be used in occasions that require anti-static or conductive properties.

– Wear resistance: The reinforcing effect of carbon fibers improves the wear resistance of PC CF10, giving it a longer service life in friction and wear environments.

– Lightweight: Compared with metal materials, PC CF10 has a lower density, enabling lightweight design and reducing the weight of products.

One Case in Modern Construction Industry

In the modern construction industry, PC 10%CF plays a crucial role, particularly when used in architectural facades such as sunshades. These applications demand high-performance materials.

PC resins with 10% carbon fiber reinforced, developed by Carbon (Xiamen) New Material, exhibit exceptional impact resistance and excellent dimensional stability. Under conditions of strong winds or accidental impacts, sunshades made from conventional materials might crack or deform. In contrast, polycarbonate + 10% carbon fibers can withstand significant impacts, maintaining its integrity and functionality. Additionally, its superior dimensional stability ensures that the sunshade remains unaffected by fluctuations in temperature and humidity, thereby preserving the aesthetic appeal and overall performance of the building facade.

A prominent commercial building has utilized PC CF 10 for its sunshades. Over an extended period of use, these sunshades have proven resilient against severe weather conditions, including intense storms and extreme temperature variations, without any signs of damage, deformation, or dimensional changes. This performance enhancement not only boosts the building’s safety and durability but also reduces maintenance costs, ensuring long-term stability and operational efficiency of the building.

Another Case in Electronic Devices

In the field of electronic devices, PC – CF10 has an outstanding performance. Take the shell of high-end laptops as an example, which has quite high requirements for the performance of materials.

PC + CF10% has good impact resistance and excellent heat dissipation. In daily use, laptops will inevitably be knocked. However, PC CF10 can effectively resist the impact and protect the internal components. At the same time, its excellent heat dissipation performance can ensure that the computer does not overheat during high-intensity operation.

A well-known brand of high-end laptops adopts 10%CF PC provided by Carbon (Xiamen) New Material Co., Ltd. as the shell material. After long-term use, there are no obvious scratches and deformations on the computer shell, and the heat dissipation effect is still good, which greatly improves the user experience.

Please click here to learn more about carbon fiber filled PC compounds,

If you had any questions or interest in PC carbon fiber composites, please feel free to contact us.

What is Polycarbonate?

Polycarbonate is a multifunctional, resilient thermoplastic renowned for its high impact tolerance, optical transparency, and heat resistivity. It is frequently utilized in a variety of applications such as eyewear lenses, safety screens, and construction materials. PC is manufactured by the polymerization of carbonate monomers, yielding a material that is both lightweight and robust. It can be readily shaped and fabricated, rendering it appropriate for diverse industrial and consumer goods. Owing to its capacity to endure high temperatures and physical impacts, PC is frequently selected for exacting environments and applications.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.