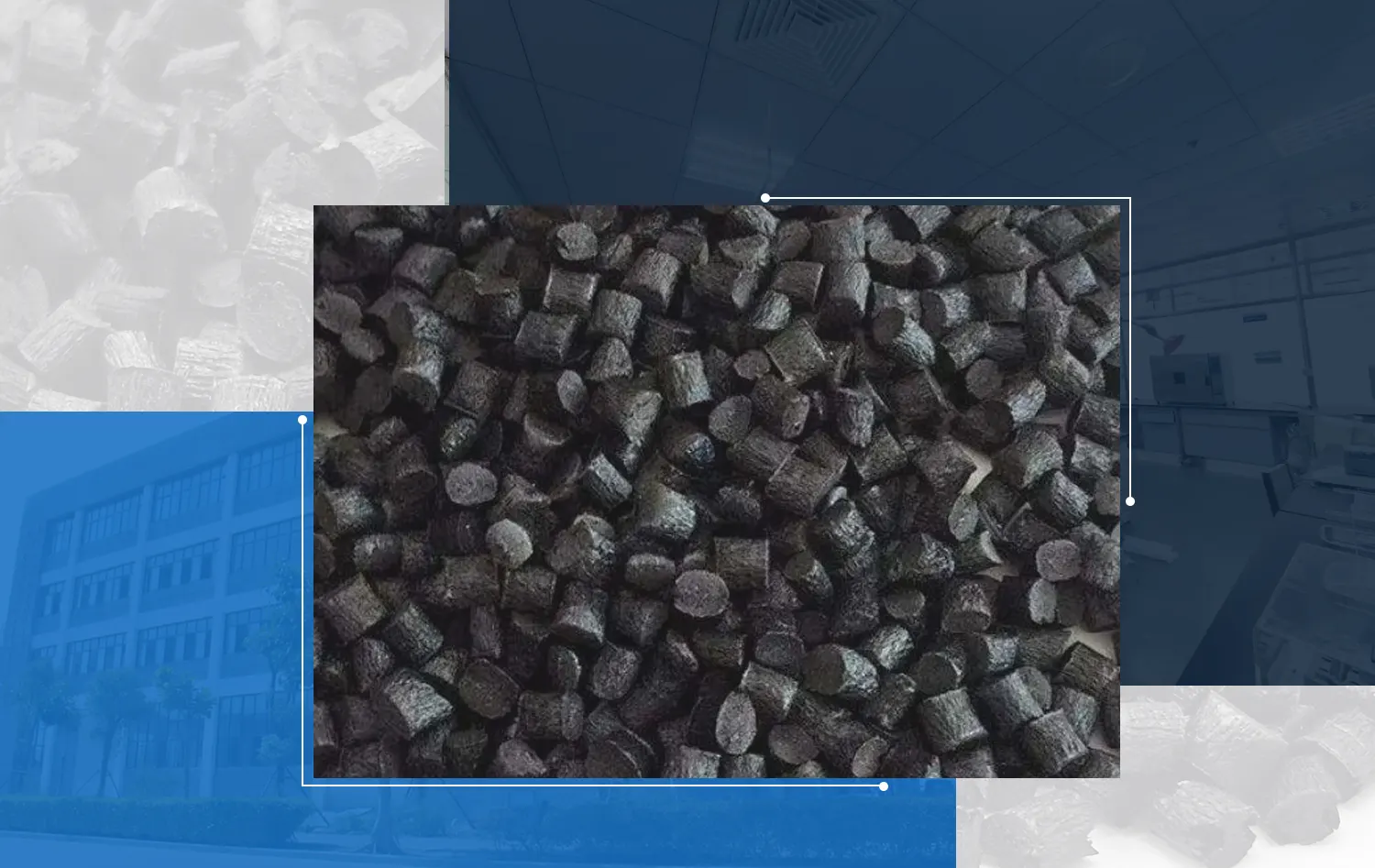

Extrusion PA6 CF 30 For 3D Printing

PA6 CF 30, a thermoplastic composite material, is a leading choice for applications in chemical processing equipment, automotive, aerospace, and industrial machinery. Its high toughness, fatigue resistance, and excellent wear resistance make it ideal for moving parts. PA6 CF 30 also exhibits excellent tribological performance, making it suitable for applications involving moving parts. Carbon Xiamen New Material offers customization options and technical support to meet or exceed expectations.

- Matrix resins: Nylon PA6

- Model number: PA6-CF-BCA3

- Types: Virgin/recycled

- Molding process: Extrusion molding

- Filler: Carbon fibers

- Manufacturer: Yes

- OEM/ODM: Acceptable

Why to choose extrusion grade PA6 CF30 for 3D printing?

PA6 CF 30, or Carbon Fiber Reinforced Nylon 6 with 30% carbon fiber, is particularly well-suited for 3D printing for several key reasons:

1. Enhanced Mechanical Properties: The addition of 30% carbon fiber significantly improves the tensile strength and stiffness of PA6. This results in parts that are much stronger and more rigid compared to standard nylon. This makes it ideal for producing high-performance components that need to withstand substantial mechanical loads.

2. Reduced Warping: Carbon fibers help to lower the thermal expansion coefficient of PA6, which means that the material is less prone to warping and shrinkage during the cooling process. This stability helps in achieving high precision and dimensional accuracy in printed parts.

3. Improved Wear Resistance: The carbon fiber reinforcement enhances the wear resistance of PA6, making it suitable for parts that experience friction and abrasion. This is particularly beneficial for components like gears and mechanical parts that require durability and long-term performance.

4. Good Printability: PA6 CF 30 maintains a balanced flow during the printing process, which helps in achieving consistent layer adhesion and reducing common printing issues like clogging or poor layer bonding. It can be printed at relatively high speeds without sacrificing quality, which can improve overall production efficiency.

5. Thermal Stability: The material’s thermal stability is enhanced due to the carbon fibers, which helps in maintaining structural integrity at higher temperatures and during thermal cycling. This property is crucial for parts that will be exposed to varying thermal conditions in their applications.

These characteristics make PA6 CF 30 a preferred choice for applications requiring both strength and precision, such as aerospace, automotive, and industrial machinery components.

Which auto parts are made of PA6 CF30 by 3D printing?

In the automotive industry, vehicle manufacturing enterprises choose to use PA6 CF 30 composite material to meticulously create a lightweight wheel bracket. PA6 CF 30 is a nylon composite material containing 30% carbon fibers, which has always been renowned for its extraordinary and outstanding strength, extremely rigid stiffness, and remarkable high-temperature resistance characteristics.

It should be known that traditional wheel brackets are often manufactured using metal materials. Admittedly, metal materials are strong and durable, but they inevitably significantly increase the overall weight of the wheels.

The automotive enterprises have shown ingenuity and developed a prototype of the wheel bracket using 3D printing technology. Relying on the remarkable high-strength characteristics of PA6 CF 30, this wheel bracket demonstrates more excellent durability when bearing loads. At the same time, it has successfully significantly reduced its own weight. With the aid of this advanced 3D printing technology, they were able to ingeniously achieve extremely complex geometric shapes in the design stage, and such complex shapes were simply an unattainable dream in traditional manufacturing methods.

The final wheel bracket not only significantly reduces the weight of the vehicle body, thereby greatly improving the fuel utilization efficiency, but also greatly enhances the vehicle’s handling performance and safety guarantee level.

After a series of extremely strict tests, this wheel bracket has astonishingly excellent performances under various environmental conditions. In actual use, the vehicle’s power performance has been significantly improved, and the commendable durability of the wheel bracket has also successfully passed the numerous tests of practice. This remarkable successful application case clearly highlights the huge potential of PA6 CF 30 composite material in the field of 3D printing and provides a new and extremely valuable solution for the research and development of lightweight and high-performance components in the future automotive industry.

Learn more about carbon fiber reinforced nylon 6 composites, please click here.

If you are interested in our products, please do not hesitate to contact us.

Extrusion PA6 CF 30 For 3D Printing Guide

PA6 CF 30 manufactured by Carbon Xiamen New Material, a thermoplastic composite material, is a leading choice for applications in chemical processing equipment, automotive, aerospace, and industrial machinery. Its high toughness, fatigue resistance, and excellent wear resistance make it ideal for moving parts. PA6 CF 30 also exhibits excellent tribological performance, making it suitable for applications involving moving parts. Carbon Xiamen New Material offers customization options and technical support to meet or exceed expectations.

Three Main Features of CF

The main reasons why carbon fiber is suitable for 3D printing include: High strength: Carbon fiber has a very high tensile strength, which can reach 2 to 7 GPa, and can enhance the strength and stability of 3D printed components. For example, continuous carbon fiber can be inlaid in thermoplastic using the continuous filament fabrication (CFF) technology to form the "backbone" of the printed component, resulting in a hard, strong and durable effect. It is an economical and effective solution, and 3D printed composite components can be used to replace traditional metal components because it can achieve similar strength with only a small part of the weight. Light weight: The density of carbon fiber is small. Its specific gravity is lighter than that of aluminum and less than 1/4 of that of steel. Its density is approximately 1.5 to 2.0 grams per cubic centimeter. This enables the 3D printed products to reduce the overall weight while ensuring strength and achieve lightweighting. Excellent dimensional stability: The thermal expansion coefficient of carbon fiber has the characteristics of anisotropy, and its dimensional stability is good, which helps to improve the accuracy and quality of 3D printed products.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.