Enhanced Mechanical of PP-CF40

- Model number: PP-CF-BCA4

- Matrix Resin: Polypropylene (PP)

- Reinforcing Filler: Carbon fiber

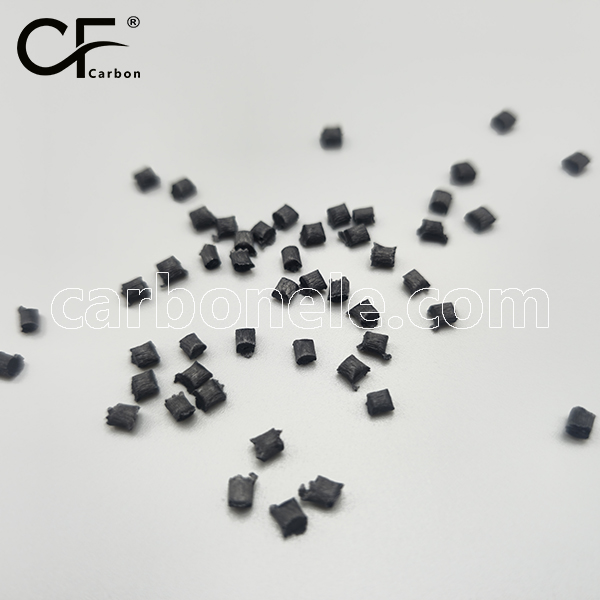

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PP-CF40 Introduction: 40% Carbon Fiber Reinforced Polypropylene

PP-CF40 is a composite material created by blending polypropylene (PP) with 40% carbon fiber (CF). Polypropylene, a well-established plastic known for its low cost, lightweight nature, and chemical resistance, has certain limitations in terms of strength and thermal stability. The incorporation of carbon fiber effectively addresses these deficiencies, significantly enhancing the mechanical properties of PP-CF40 and expanding its applicability across various sectors.

The Role of Carbon Fiber

Carbon fiber consists of extremely fine fibers composed primarily of carbon atoms, offering high strength while remaining lightweight. Consequently, the integration of carbon fiber with polypropylene not only bolsters the strength and rigidity but also preserves the material’s lightweight characteristics. Specifically, the “40” in PP-CF40 denotes that 40% of the composition is carbon fiber while the remaining 60% comprises polypropylene. This synergy results in substantial performance enhancements.

Key Features of PP-CF40

Enhanced Strength and Rigidity: A prominent characteristic is that PP-CF40 exhibits significantly greater strength compared to standard polypropylene. While unmodified polypropylene tends to be relatively soft and malleable, incorporating carbon fiber transforms it into a harder and more durable material capable of enduring higher pressures—making it suitable for manufacturing components requiring elevated strength.

Lightweight Composition: Despite its enhanced strength attributes, PP-CF40 remains remarkably lightweight due to the inherent properties of carbon fiber. It boasts an exceptional strength-to-weight ratio that renders it particularly advantageous for applications necessitating both lightness and robustness—such as those found in automotive or aerospace industries.

Improved Thermal Resistance: Although traditional polypropylene displays suboptimal heat resistance prone to softening at elevated temperatures, adding carbon fiber enables PP-CF40 to retain its structural integrity under higher thermal conditions. This quality allows for utilization in high-temperature environments like engine components or industrial machinery.

Chemical Corrosion Resistance: Retaining polypropylenes’ commendable chemical resistance capabilities against various acids, bases, and organic solvents ensures that PP-CF40 maintains stability even within harsh chemical settings—a feature highly valued within the chemical industry.

Antistatic Properties: The conductive nature inherent to carbon fibers imparts antistatic qualities to PP-CF40; this attribute proves essential for electronic component applications sensitive to static electricity by effectively mitigating static charge accumulation thereby safeguarding equipment from electrostatic damage.

Practical Applications of PP-CF40

Given these superior performance characteristics, PP-CF40 finds extensive application across multiple industries:

In Automotive Manufacturing: Commonly utilized for producing parts such as bumpers, instrument panels,and interior fittings; its combinationof light weightand high-strength contributes towards reducing overall vehicle mass while improving fuel efficiency.Additionally,it’s heat-resistant properties renderit suitableforengine-relatedcomponents.

Aerospace Sector: In aviation where weight reductionis paramount ,PP CF40 emergesas an idealmaterialfor criticalaircraftand spacecraftcomponentsdueits remarkablestrength-to-weightratio.Sports Equipment Production : High-performance sports gear including bicycles ,helmets ,tennis rackets etc.,benefitfromthelightweight yet sturdycharacteristics of PP CF40 greatlyenhancinguserexperience.

Electronic Devices: Thanks totheantistaticpropertiesofthiscomposite ,it hasalso secureditsplacein electronics .Static electricity poses significant risks toelectroniccomponents; henceusing PP CF40mitigatespotentialissuesbypreventingchargeaccumulation ensuringstableoperationofdevices .

Industrial Machinery Components : PP CF40 also plays a crucial role in industrial applications that demand high pressure and chemical corrosion resistance, particularly in environments where intense mechanical stress is anticipated. Its strength and chemical resilience are outstanding.

Conclusion

PP-CF40 is a composite material made by blending polypropylene (PP) with 40% carbon fiber (CF). This material, known for its low cost, lightweight nature, and chemical resistance, has limitations in strength and thermal stability. The addition of carbon fiber enhances the material’s mechanical properties and expands its applicability across various sectors. PP-CF40 exhibits enhanced strength and rigidity, making it suitable for manufacturing components requiring elevated strength. Its lightweight composition allows it to remain remarkably lightweight, making it suitable for high-temperature environments like engine components or industrial machinery. PP-CF40 also offers improved thermal resistance, allowing it to maintain its structural integrity under higher thermal conditions.

It also maintains chemical corrosion resistance, ensuring stability even in harsh chemical settings. The conductive nature of carbon fibers imparts antistatic properties, making it essential for electronic component applications sensitive to static electricity. PP-CF40 finds extensive application across various industries, including automotive manufacturing, aerospace, sports equipment production, electronics, and industrial machinery components. Its lightweight yet sturdy characteristics contribute to reducing vehicle mass and improving fuel efficiency. The composite’s antistatic properties also secure its place in electronics, mitigating potential issues by preventing charge accumulation.

If you want to get more information about PP-CF40, you can vist our Youtube.

Click here to contact us.

PP-CF40 granules

PP-CF40 granules are tiny pellets composed of polypropylene and five percent carbon fiber for reinforcement. The enhanced strength and rigidity offered by carbon fibers are combined with the lightweight and chemical-resistant qualities of polypropylene to create this composite material.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.