Engine Intake Manifold Raw Material PPS LCF50

PPS LCF50 has excellent properties. It offers high temperature resistance up to 260°C, outstanding mechanical strength, low water absorption, chemical corrosion resistance, dimensional stability, and good electrical insulation.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model: PPS-LCF-BCA5

- Filler: Long carbon fiber

I. Material Composition and Performance Advantages

PPS LCF50 is mainly composed of polyphenylene sulfide (PPS) and long carbon fiber with a content as high as 50%. This unique material has a series of remarkable performance advantages that are truly eye-catching.

1. Excellent high temperature resistance: PPS-LCF50 can still exhibit excellent mechanical properties in extremely high temperature environments. Its heat resistance is as high as 260°C. Even in extremely hot working scenarios, it can maintain a good state stably. Whether in high-temperature industrial furnaces or in the high-temperature parts of engines, PPS LCF50% can handle it calmly and provide reliable protection for various high-temperature applications.

2. Outstanding mechanical strength: The strong reinforcement effect of carbon fiber has greatly increased the tensile strength and compressive strength of PPS LCF50. Under high loads, it can still show amazing stability. This strong mechanical strength makes PPS LCF50 an ideal material for manufacturing high-load mechanical parts. Whether it is bearing huge tensile forces or resisting strong pressures, it is as firm as a rock and provides solid support for various engineering applications.

3. Low water absorption: The LCF50-PPS material hardly absorbs water at all. This characteristic ensures its high stability in humid environments. No matter how humid the surrounding environment is, it can maintain its own performance without being affected. In humid climates or in application scenarios that need to come into contact with water, PPS LCF 50 can perform stably and provide an ideal choice for various equipment and components that need to operate in humid conditions.

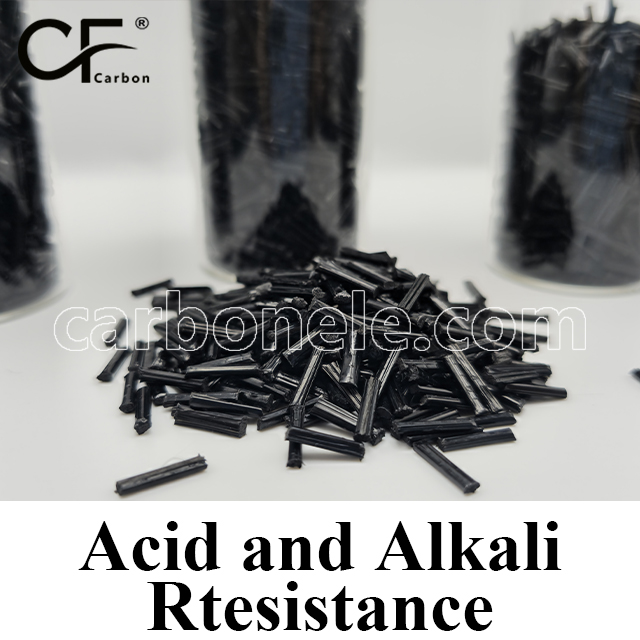

4. Excellent chemical corrosion resistance: PPS LCF50 has excellent corrosion resistance to various chemicals such as acids, alkalis, and salts. In harsh chemical environments, it can still function safely. Whether in a corrosive environment of strong acids and alkalis or in a marine environment with high salinity, PPS-LCF50 can maintain good performance and is very suitable for use in various harsh chemical environments.

5. Outstanding dimensional stability: The dimensional change of the material is extremely small at high temperatures, which is crucial for maintaining the shape and size of precision parts. In high-temperature working environments or in complex manufacturing processes, PPS LCF50% can ensure dimensional accuracy. Whether manufacturing high-precision electronic devices or producing precision mechanical parts, LCF50% PPS can provide reliable dimensional stability protection for them.

6. Good electrical insulation performance: PPS+LCF50 has excellent electrical insulation characteristics and can effectively prevent short circuits and interference. In electrical and electronic applications, it can provide safe and reliable insulation protection for electronic devices and electrical equipment. Whether inside high-temperature electronic devices or in occasions that require good electrical insulation performance, LCF50-PPS can play an important role.

II. Application Fields of PPS LCF60

PPS LCF50 is widely used in many important fields, and its application range is astonishing.

– Automotive industry: In the automotive industry, PPS LCF50 is widely used in manufacturing key parts such as engine components and exhaust system components. Due to its high temperature resistance and high strength characteristics, it can provide reliable performance guarantees for cars in harsh working environments. In the high-temperature engine compartment, engine parts made of PPS LCF50 can withstand the tests of high temperature and high pressure to ensure the normal operation of the engine. In the exhaust system, exhaust system components made of PPS LCF50 can resist the corrosion of high-temperature exhaust gas and extend the service life of the exhaust system.

– Aerospace field: In the aerospace field, PPS LCF50 also has important applications. It is used in high-tech products such as aircraft structural parts and satellite components. It is favored because of its lightweight and high temperature resistance properties. In the vast sky and the vast universe, PPS LCF50 can provide stable performance support for aircraft and satellites under extreme environmental conditions. Its lightweight characteristic helps to reduce the weight of aircraft and improve fuel efficiency; while its high temperature resistance performance can ensure that the structural parts of aircraft and satellites can still maintain good performance in high temperature environments.

– Electronic and electrical field: In the electronic and electrical field, PPS-LCF50 is suitable for electronic device casings, electrical insulation parts, etc. With its good electrical insulation performance and excellent high temperature resistance characteristics, it provides reliable protection for the safe operation of electronic equipment. Inside high-temperature electronic devices, the electronic device casing made of LCF50-PPS can effectively protect electronic components and prevent overheating and short circuits. In electrical insulation parts, the excellent electrical insulation performance of PPS LCF50 can ensure the safe operation of electrical equipment and prevent leakage and interference.

– Industrial equipment field: In the field of industrial equipment, LCF50-PPS is used to manufacture high-load mechanical parts and gears and is widely concerned because of its strong wear resistance. In industrial production, high-load mechanical parts and gears need to have extremely high wear resistance and strength, and PPS LCF50 just meets these requirements. It can maintain good performance for a long time in a high-load working environment and provide strong support for the efficient operation of industrial equipment.

III. Application Case

At the beginning of this year, Carbon (Xiamen) New Material successfully applied LCF50-PPS to the engine intake manifold of a high-end sports car. This intake manifold faces many severe challenges and needs to withstand the tests of high temperature, high pressure and chemical corrosion. The high temperature resistance and high strength of PPS LCF50 can just meet these harsh requirements.

Specifically, when the engine is working, the temperature is as high as 250°C. Traditional materials are often difficult to be qualified in such a high temperature environment, but PPS LCF50 performs extremely stably in this environment. During the use of the intake manifold, LCF50-PPS not only maintains good structural strength but also effectively reduces the intake air temperature, thereby significantly improving the overall performance of the engine.

According to detailed test data, the high temperature tolerance of this material has extended the service life of the intake manifold by 30%. This means that the intake manifold made of PPS-LCF50 can maintain good performance for a longer time, reducing engine failures caused by damage to the intake manifold and improving the reliability and durability of sports cars. At the same time, PPS LCF50% also reduces heat loss by 15%. This advantage not only improves the thermal efficiency of the engine, reduces fuel consumption, but also reduces thermal pollution to the environment.

These advantages not only greatly improve the performance of sports cars but also reduce maintenance costs, bringing significant economic benefits to manufacturers. Therefore, the PPS+LCF50 composite material of Carbon (Xiamen) New Material has won wide recognition and praise in the industry and has become a crucial part of high-end car manufacturing.

If you want to obtain more information about carbon fiber reinforced and modified thermoplastic composites by watching videos, please click here. Thank you.

How to Purchase?

Acquire information on product specifications, performance, prices and so on. Select an appropriate product based on your own requirements. Additionally, you can request the manufacturer to supply samples for testing to make sure the material meets your usage needs. If you are interested in buying this composite material, contact Carbon (Xiamen) New Material, the manufacturer, directly.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.