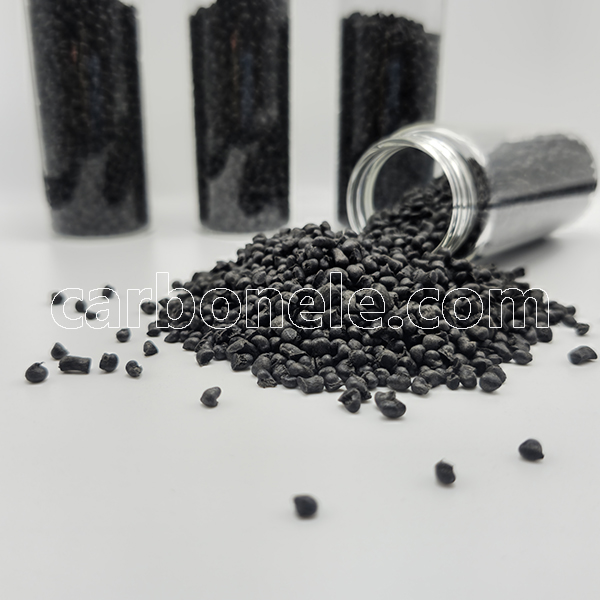

Wear Resistance CF30 PPA Pellet Raw Materials for Sprockets

CF30 PPA has characteristics like high tensile strength, excellent heat resistance, low thermal expansion, good chemical resistance, etc., making it useful in various applications.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model: PPA-CF-BCA3

- Fillers: Carbon fiber

Characteristic of CF30 PPA

1. High Tensile Strength: Carbon fiber boosts PPA’s tensile strength, resisting deformation under load, vital for strong structures.

2. Excellent Heat Resistance: PPA and carbon fiber are thermally stable, withstanding high temperatures without degradation.

3. Low Coefficient of Thermal Expansion: PPA and carbon fiber combo means low expansion, keeping dimensions stable in varied temperatures.

4. Good Chemical Resistance: PPA resists chemicals like automotive fluids. Carbon fiber doesn’t affect this, fitting harsh settings.

5. Electrical Conductivity: PPA is insulating, but carbon fiber can add some conductivity for ESD protection needs.

6. High Stiffness: Carbon fiber makes the material stiffer, resisting bending and flexing, good for shape – holding parts.

7. Wear Resistance: Carbon fiber gives great wear resistance, enduring friction, extending lifespan in moving or rubbing parts.

8. Dimensional Stability: Low thermal expansion and fiber reinforcement keep CF30 PPA’s dimensions steady in changing conditions.

Successful Case

CF30 PPA was utilized to manufacture sprockets for conveyor belt systems in a leading industrial machinery company. These sprockets were installed in a factory’s heavy-duty conveyor line, tasked with moving large, heavy materials across the facility. The sprockets, made from CF30 PPA, demonstrated remarkable durability and strength, withstanding the constant friction and heavy loads without significant wear. Their excellent heat resistance ensured stable performance even in the hot environment of the factory. The low coefficient of thermal expansion maintained precise alignment with the conveyor chain, reducing maintenance needs. Additionally, the sprockets’ chemical resistance protected them from the corrosive effects of industrial oils and chemicals. As a result, the conveyor system’s efficiency and reliability improved, leading to increased productivity and cost savings for the company. This successful application of CF30 PPA sprockets set a new standard for material selection in industrial settings.

Applications of CF30 PPA

| Application Field | Specific Usage Examples | Corresponding Advantage Descriptions |

|---|---|---|

| Electronics and Electrical Appliances Field | – Electronic connectors: Used in connectors on computer motherboards and in mobile phones. – Switch components: Making the shells and keys of electrical switches. – Relay housings. |

– Good dimensional stability ensures stable shape and performance during frequent insertions and removals, guaranteeing reliable electrical connections. – High temperature resistance and wear resistance can withstand repeated operations and heat generated during equipment operation, ensuring normal work. – It has good mechanical protection, chemical resistance and stable electrical properties to protect the key internal components. |

| Automotive Industry Field | – Engine peripheral components: Such as pipe connectors in the cooling system and sensor housings. – Automotive interior parts: The skeleton structures of some control buttons and handles in high-end models. |

– High temperature resistance can resist the erosion of coolants, engine oil and other media and withstand the vibration of the engine. – High strength ensures a solid structure, and it can be processed to have a good texture appearance to meet the interior requirements. |

| Aerospace Field | – Small structural parts: Small brackets and connectors inside aircraft. | – It can achieve lightweight while meeting certain strength requirements and has comprehensive performance such as high temperature resistance, adapting to the aerospace environment. |

| Industrial Manufacturing Field | – Mechanical transmission parts: Small gears, sprockets, etc. – Industrial sensor housings. |

– It has good wear resistance and self-lubricating properties (in some cases), which can replace some metal materials, reduce costs, reduce weight and have low operating noise. – It can withstand dust, chemical corrosion and temperature changes, providing reliable protection for sensors. |

If you’d like to buy Wear Resistance CF30 PPA Pellet Raw Materials for Sprockets or understand more carbon fiber reinforced thermoplastic polymers (CF-RTPs) produced by Carbon New Material Xiamen , please feel free to contact us at any time.

Learn more about CF-RTP Composites, please click here.

Get to Know Carbon Fiber

Carbon fiber features high strength with its tensile strength exceeding that of many traditional materials, high modulus resulting in little deformation under force, low density making it lightweight, good high-temperature resistance, chemical stability, as well as electrical and thermal conductivity. According to strength, it can be roughly divided into general-purpose types (T300 grade), high-strength types (T700 and T800 grades), and ultra-high-strength types (T1000 grade and above), each having different application focuses.

Why Choose Us?

Carbon (Xiamen) New Material Co., Ltd. stands out for its expertise in CFRTPs. We possess cutting-edge tech, ensuring top-notch product quality. Our dedicated team offers personalized service and strict quality checks. Choose us for reliable materials and a seamless cooperation experience.

How to Buy?

If you want to obtain information such as product specifications, performance, and price, choose a suitable product according to your own needs. Meanwhile, you can ask the manufacturer to provide samples for testing to ensure that the material meets your usage requirements. If you are interested in purchasing this composite material, please contact the manufacturer Carbon (Xiamen) New Material directly.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.