Best Price Per KG PBT CF40 China Supplier

PBT CF40 is a specialized thermoplastic. It combines high performance and durability. The carbon fiber reinforcement boosts its properties. Key features include mechanical strength, thermal stability, chemical resistance, and dimensional stability. It’s used in automotive, electrical, industrial, and consumer goods. Consider factors for best price and quality.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

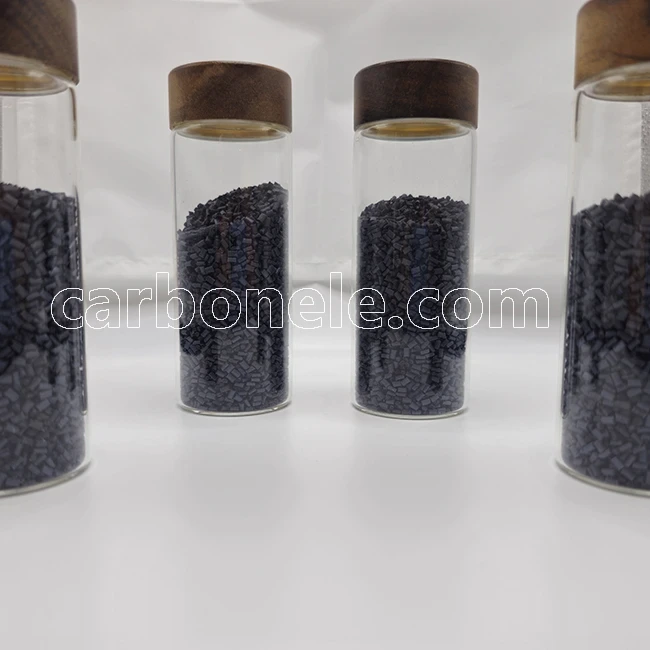

- Color: Black

- Free Samples: ≤25kgs

- MOQ: 100kgs

- Port: Xiamen

- Model No.: PBT-CF-BCA4

What’s PBT CF40?

PBT CF40 is a specialized type of thermoplastic polymer known for its high performance and durability. PBT stands for Polybutylene Terephthalate, a crystalline polymer known for its robustness and resistance to wear and tear. The “CF40” designation typically indicates a specific formulation or grade of PBT that includes carbon fiber reinforcement, enhancing its mechanical properties.

Key Characteristics:

1. Mechanical Strength: PBT CF40 incorporates carbon fibers, which significantly boost its tensile strength and rigidity. This makes it highly suitable for applications requiring high structural integrity.

2. Thermal Stability: The material exhibits excellent thermal resistance, maintaining its properties even at elevated temperatures. This stability ensures that it performs reliably in various thermal environments.

3. Chemical Resistance: PBT CF40 is resistant to a broad range of chemicals, including oils, greases, and solvents. This property makes it ideal for use in harsh chemical environments.

4. Dimensional Stability: The carbon fiber reinforcement contributes to minimal thermal expansion and contraction, ensuring precise dimensional stability even under fluctuating temperature conditions.

5. Low Moisture Absorption: PBT CF40 has low moisture absorption rates, which helps maintain its mechanical properties and dimensional stability in humid conditions.

Applications:

1. Automotive Industry: Its high strength and thermal resistance make PBT CF40 ideal for automotive components, including engine parts, structural components, and interior parts. It helps in reducing weight while enhancing performance and durability.

For instance, imagine a high-performance electric car. The battery casing is made of PBT CF40. This ensures the battery is protected from the heat generated during charging and discharging, while also withstanding the vibrations and impacts from the road. The lightweight nature of the material contributes to improved energy efficiency and range of the vehicle.

2. Electrical and Electronics: The material is used in electrical and electronic components due to its excellent insulation properties and resistance to electrical interference. This includes connectors, housings, and circuit boards.

3. Industrial Equipment: PBT CF40 is employed in various industrial applications where high mechanical strength and chemical resistance are critical, such as machinery parts and housings for equipment.

4. Consumer Goods: It is also used in consumer products that require a combination of strength, durability, and aesthetic quality, such as in some high-end consumer electronics.

Cost and Quality Considerations

Finding the best price for high-quality PBT CF40 involves considering several factors:

1. Supplier Reputation: Opt for suppliers with a proven track record of delivering high-quality PBT CF40. Check for certifications and customer reviews.

2. Bulk Purchasing: Buying in bulk can often reduce the per-unit cost. Consider this if you have ongoing needs for the material.

3. Material Grade: Ensure that the PBT CF40 you are purchasing meets the specific grade and quality standards required for your application. Some suppliers offer different grades that vary in performance and price.

4. Market Trends: Keep an eye on market trends and fluctuations in raw material prices, as these can affect the cost of PBT CF40.

5. Supplier Negotiations: Engage with multiple suppliers to negotiate the best price. Sometimes suppliers offer discounts or better terms for large orders or long-term contracts.

PBT CF40 is a high-performance material renowned for its mechanical strength, thermal stability, and chemical resistance, making it suitable for a wide range of demanding applications. To obtain the best price while ensuring high quality, consider reputable suppliers, bulk buying options, and ongoing market trends.

Learn more about carbon fiber reinforced PBT compounds, please click here or watch videos on CFRTPs on YouTube.

Why to Choose us?

Integrating research and development, manufacturing and sales, relying on an adept R&D team, the modern and advanced production facility and scrupulous pre-sale and after-sale services, Carbon (Xiamen) New Material is devoted to furnishing superior-quality carbon fiber reinforced thermoplastics, creating all-inclusive one-stop services and offering all-round comprehensive solutions of CFRTP products. Recently, we have successfully developed innovative products that meet the specific needs of diverse clients, showcasing their commitment to excellence and customer satisfaction.

Stringent Quality Control System

Carbon (Xiamen) New Material has adopted a thorough quality inspection process from raw material selection to finished product dispatch. High-precision tests are conducted in raw material procurement. Each production stage is closely watched and sampled. Non-destructive testing is used to identify flaws in the final products. This meticulous method, along with continuous improvement based on quality data analysis, guarantees that every factory-outgoing product meets or exceeds the strictest industry standards. A notable example is their zero-defect record for a specific high-demand product line.

Abundant Industry Experience

Years of involvement have bestowed Carbon (Xiamen) New Material with vast production and trade expertise. It provides supplies for major projects, boosting its capabilities and reputation. Actively taking part in global events, it stays updated on trends and acquires information for growth. By capitalizing on this experience, the company can predict market changes and proactively modify its strategies and product ranges to remain pertinent and competitive. A remarkable project they participated in established new industry benchmarks for quality and delivery.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.